|

Vol. 231 No. 2 |

|

|

PRAMOD KULKARNI, CONTRIBUTING EDITOR

|

Inject electricity and pump more oil?

Electrical stimulation to cure an aching back or grow hair over a bald spot seems within the realm of possibility. But to increase oil production and reduce watercut? You’ve got to be kidding, right? Despite the snake oil overtones, serious efforts have been underway in Russia, the United States and Canada to improve the production of viscous reservoirs through electrical stimulation. In 2008 and late 2009, there have been laboratory and field trials with reported successful results.

Most enhanced oil recovery methods have relied on hydraulic methods. Various fluids (natural gas, CO2, nitrogen, water and/or steam) are injected to displace the oil in place. These methods have typically achieved increases of 15–20% in oil production. In addition to these hydraulic methods, researchers have conducted experiments to test a variety of energy fields (thermal, ultrasonic, magnetic, high-frequency and electromagnetic) to change the properties of the oil in place or the residual water.

Stimulation by electro-osmosis. In 2008, E. A. Ivliev with the St. Petersburg State Marine Technical University in Russia reported on an electro-osmotic method to improve the operating efficiency of oil wells.1 K. P. Tikhomolova had already published a paper on this method in 1993. Electro-osmosis causes protons to drag water molecules from one side (anode) to the other (cathode). According to Ivliev, it is possible to create an electro-osmotic flow most efficiently by setting up the bottom of a well as a bipolar electrode.

Ivliev tested this method in a laboratory setup wherein 100 mA of current flowed between the electrodes. He reported: “Within 1.5 minutes after the beginning of the electro-osmotic treatment, oil began to appear. After 35 minutes, the power supply was switched off; in the process, the liquid filtration rate decreased approximately by a factor of 10, and output of oil completely ceased.”

There is, of course, a world of difference between a laboratory simulation and practical results. There are no reports of field tests for the Russian electro-osmotic method.

Enhanced recovery using direct current. Investigations of electro-osmosis and related processes in the US go back to lab experiments by George V. Chilingar and his students at the University of Southern California starting in the 1960s. A leading petroleum geologist, Chilingar is credited with the development of geological methods leading to the discovery of major fields in Iran, Saudi Arabia and offshore Thailand.

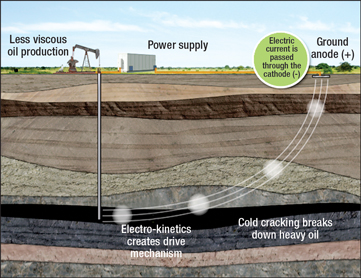

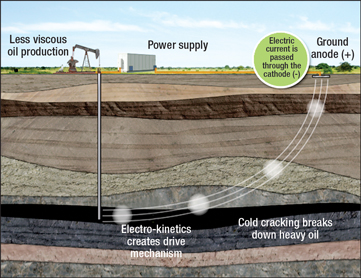

Recent efforts to commercialize the application of direct current for enhanced oil recovery in heavy oil reservoirs began at General Electric and are now being spearheaded by Electro-Petroleum Inc. (EPI). J. K. Wittle, the company’s chief technology officer, has authored several SPE papers on the topic, one of them co-authored by Chilingar, and has contributed to its field implementation.2 EPI implements its proprietary Electrically Enhanced Oil Recovery (EEOR) process by passing direct current between cathodes in the producing reservoir and anodes at either the surface or depth, see figure.

According to EPI, five mechanisms, collectively called electro-kinetics, aid the production enhancement process: Joule heating raises the reservoir temperature and lowers the crude’s viscosity. Electro-migration enables charged particles to migrate from the anode to the cathode. Eletro-phoresis clears pore throats and improves permeability. Electro-osmosis dewaters expansive clays and increases apparent reservoir permeability. Electro-chemically enhanced reactions cause “cold cracking” of the heavy crudes, resulting in simpler hydrocarbon products with lower viscosity.

EEOR field implementation. EPI first demonstrated EEOR in California’s Santa Maria Basin over a period of six years. The demonstration reservoir is 100-ft-thick unconsolidated sand at a depth of 2,800 ft. EPI’s process was tried after unsuccessful steamflooding and cyclic steam injection. The baseline production was 5 bopd of 8.1°API crude with a 45% watercut. Upon EEOR application, EPI has reported a tenfold increase in heavy oil production and a 12% watercut reduction.

In October 2009, EPI reported the results of a pilot test at Deloro Resources’ Wilkie Field in Saskatchewan. EPI retrofitted an existing horizontal well and was able to improve the API gravity and reduce the viscosity of the oil by about 50%. No production improvement was reported, but the company stated that several issues with the existing well configuration limited potential flowrate. The joint venture now plans to address these issues and will proceed with the development of new wells custom designed for the EEOR process. According to EPI, its process has costs similar to those of steamflooding with no depth limitations, does not require either a water supply or a working fluid, and has a smaller carbon footprint.

Technological evolution. Electrical methods for enhanced recovery demonstrate the typical growing pains of technological evolution. Just as in its biological counterpart, this process involves multiple parallel paths, offshoots and frequent dead ends. How electrical methods of increasing production will evolve in future oil fields remains to be seen.

LITERATURE CITED

1 Ivliev, E. A., “Enhancement of the operating efficiency of oil wells by electrical treatment of the bottom-hole area,” Surface Engineering and Applied Electrochemistry, 45, No. 1., 2009, pp. 21–25.

2 Wittle, J. K., Hill, D. G. and G. V. Chilingar, “Direct current electrical enhanced oil recovery in heavy-oil reservoirs to improve recovery, reduce water cut and reduce H2S production while increasing API gravity,” SPE 114012 presented at the SPE Western Regional and Pacific Section AAPG Joint Meeting, Bakersfield, Calif., March 31–April 2, 2008.

|

In EPI’s electrical stimulation process, current is passed from an anode on the surface to the cathode at the bottom of the well.

|

|

|

Pramod Kulkarni is a Houston-based technology writer and editor. With a BS degree in electrical engineering from Utah State University, an MA degree in journalism from the University of Iowa and an MBA from the University of Houston, he has over 25 years of experience in writing focused on oil and gas exploration, drilling, completion and production.

|

|

|

|