Enhancing preparedness: The critical role of well control system surveys

The oil and gas industry's issues with well control challenges persist throughout the complete lifecycle of a well, from drilling and workover to production. Issues like blowouts and fires loom large, with potential consequences that can be catastrophic for personnel, the environment, and equipment. In response to this ever-present risk, a proactive approach to well control preparedness becomes paramount. Companies armed with robust well control engineering and preparedness programs not only aim to prevent well control events but also strive to minimize the associated risks, thus protecting people, environment and equipment and becoming good stewards of the society.

Cudd Well Control (CWC) has established itself as a pioneering force, offering a comprehensive suite of well control engineering services. This extensive array, ranging from emergency response and contingency planning to advanced modeling techniques, forms a strategy to enhance preparedness. Within this suite of services, the Well Control System Surveys (WCSS) stand out, providing real-time insights and diagnostics that contribute significantly to a comprehensive well control preparedness program.

Multifaceted well control engineering services. CWC's suite of well control engineering services extends far beyond mere reactive measures, incorporating proactive strategies to address potential challenges comprehensively. The Well Control Emergency Response Plan serves as a strategic blueprint for swift and effective responses during crises, offering a structured approach to minimize the impact of well control events. The Blowout Contingency Plan focuses on preemptive measures to mitigate the consequences of blowouts, an ever-present concern in well operations.

Advanced techniques, like Gas Dispersion Modeling and Kick Modeling, provide operators with invaluable insights into the behavior of gases and fluid influx, enabling fine-tuning of preventive measures. Relief Well Planning and Dynamic Kill Modeling help companies prepare for blowout response. While all the engineering services can prevent well control issues, WCSS is a dynamic tool for real-time issue identification and readiness assessment.

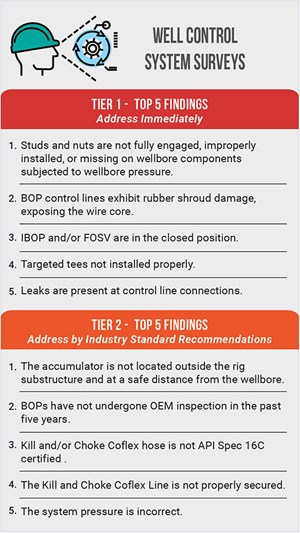

The crucial role of WCSS. Well Control System Surveys emerge as a proactive measure, capable of identifying and addressing issues to prevent potential challenges from escalating into major incidents. While traditionally performed on drilling rigs, the versatility of WCSS extends to workover, snubbing, coiled tubing, frac and various other well-related operations. The survey process involves a visual, external inspection of all well control and related equipment on site, ensuring compliance not only with regulatory standards, but also with company policies and industry best practices, Figs. 1-4.

In regions including North America, well control equipment on a drilling location undergoes a thorough visual inspection to verify compliance with standards including the American Petroleum Institute (API) Standard 53, International Association of Drilling Contractors (IADC) Drilling Manual, API RP 59 and others. This granular inspection not only identifies instances of non-compliance but also ensures that the equipment is rigged up as required, mitigating the risk of unpleasant surprises during a well control event.

Identification and resolution of issues. The strength of WCSS lies in its ability to identify and address issues on site by a competent field engineer with well control experience. This third-party survey goes beyond mere compliance checks. This proactive measure, when coupled with the expertise of personnel conducting the survey, prevents potential challenges from escalating into major incidents. By addressing issues at the root before they become critical, WCSS aligns with the overarching goal of preventing well control events rather than merely responding to them.

Regularly conducted surveys contribute to a culture of continuous improvement in well control preparedness. By identifying and rectifying issues promptly, operators and contractors significantly reduce the likelihood of well control events and minimize associated risks. This proactive approach safeguards personnel, the environment, and equipment, enhancing operational efficiency and contributing to the overall sustainability of well operations, Fig. 5.

Personnel engagement and knowledge enhancement. Beyond the critical well control equipment inspection, CWC personnel engage in meaningful dialogues with on-site teams, encompassing both operator and contractor personnel. These interactions provide a holistic understanding of the crew's well control knowledge and operational capabilities. The insights gained from these discussions are invaluable, enabling CWC to collaborate with the company in formulating crew assessment training if deemed necessary.

Crew assessment training represents a tailored approach to enhancing the well control knowledge and skills of on-site personnel. This ensures that the crew is well-prepared to handle any well control challenges that may arise, fostering confidence among operators that their teams possess the necessary expertise. This proactive engagement with personnel not only contributes to well control preparedness but also creates a collaborative and safety-oriented culture on the rig.

The evolving landscape of well control engineering. As the oil and gas industry continually evolves, driven by technological advancements and operational complexities, the role of WCSS becomes increasingly vital. In an era where drilling operations are reaching greater depths and encountering more challenging geological conditions, the need for real-time diagnostics and proactive measures is at an all-time high.

Integration of technology. Well Control System Surveys are not static procedures but are evolving alongside technological innovations. The integration of advanced technologies enhances the capabilities of WCSS. These technologies offer the potential for continuous monitoring of surveys (past and present), allowing operators to identify and address issues promptly, even from a remote location.

Cost savings. Well Control System Surveys can lead to tremendous cost savings by proactively identifying and fixings issues. Having a well-trained crew with properly rigged-up equipment can prevent well control incidents and minimize the associated risks. Another avenue of cost savings is possible discounts from insurance providers for performing preventative services. In addition, depending on the policy, the underwriters can cover the cost of the surveys.

CASE STUDY 1

In the dynamic landscape of North American unconventional shale plays, well control challenges can be exacerbated by the rapid pace of drilling operations. A well control event in such an environment can have far-reaching consequences. In this case study, a comprehensive well control preparedness program, including regular WCSS, was implemented.

The surveys identified potential issues with the pressure control equipment, providing the opportunity for preemptive maintenance. Additionally, personnel engagement revealed a gap in the crew's well control knowledge, leading to the development of targeted training programs. The combination of real-time diagnostics and personnel training not only prevented potential well control issues but also enhanced the overall competency of the on-site crew.

CASE STUDY 2

One North American operator conducted a comprehensive survey project. During this project, CWC surveyed all the operator’s operations (drilling, workover, coiled tubing and frac). Upon completion of the surveys, the findings were discussed with the operator, and a program was put in place to prevent the common findings. The operator then took it a step further and performed an overview assessment for each of their fields to check if more of the common findings from the surveys were present. This was a companywide project involving all stakeholders.

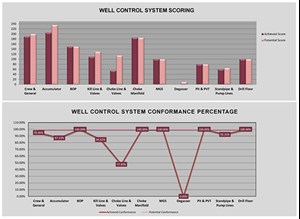

Common findings. The two charts document a variety of common findings acquired during surveys performed by CWC on the two case studies, Fig. 6.

PATH FORWARD

Looking ahead, the future of WCSS is characterized by a continued evolution to meet the challenges of a rapidly changing industry. Several key trends and advancements are shaping the trajectory of WCSS. As more sophisticated technology is being applied in well operations, there is ample data available for analysis. The incorporation of new technologies into drilling equipment, including well control equipment, enhances real-time monitoring capabilities. These devices provide continuous data streams, enabling predictive analytics and early detection of potential issues.

Electronic inspection technology. While not new, a more robust and scratch-built, fit-for-purpose, electronic inspection technology is transforming WCSS. Using cloud-based electronic inspection improves the efficiency and coverage of WCSS. This technology can provide inspection traceability and reminders on issues to be fixed/corrected.

Global standardization. As the oil and gas industry operates on a global scale, there is a growing initiative for standardization in well control practices. Well Control System Surveys are expected to align with international standards, facilitating consistency and comparability across different regions and operations.

CONCLUSION

In the dynamic and high-stakes realm of the oil and gas industry, well control preparedness is not just a regulatory requirement but a strategic imperative. Cudd Well Control's suite of well control engineering services, with Well Control System Surveys at its core, provides companies with a robust framework to enhance their preparedness. The authors attempt to outline the multifaceted challenges of well control and the pivotal role of WCSS in mitigating risks. By combining compliance checks, on-site issue resolution, personnel knowledge assessment and an examination of future trends, CWS emphasizes the holistic approach required to ensure safety, increased efficiency and sustainability of well operations throughout their lifecycle.

Continuous improvement, proactive engagement with personnel, and a commitment to well control excellence contributes to a resilient industry that prioritizes safety and environmental stewardship. As we navigate an era of technological evolution, the integration of advanced technologies with WCSS promises to redefine the landscape of well control preparedness, ensuring that the industry remains at the forefront of safety and efficiency.

Lead photo: A Cudd Well Control field engineer conducting a field survey to develop a comprehensive program that contains the best well control programs purpose-fitted for the specific drilling contractor.

- Coiled tubing drilling’s role in the energy transition (March 2024)

- What's new in production (February 2024)

- Digital tool kit enhances real-time decision-making to improve drilling efficiency and performance (February 2024)

- E&P outside the U.S. maintains a disciplined pace (February 2024)

- U.S. operators reduce activity as crude prices plunge (February 2024)

- U.S. producing gas wells increase despite low prices (February 2024)