Drilling

Webcast

Drilling Innovations & Technology Forum: Summer 2020

June 24, 2020

Schlumberger, Enventure

During this 60-minute live webcast, we will discuss the following topics: 1) “Blade Family – 3DC Cutter Technology”, with presenter, Wiley Long, Product Champion, Schlumberger. 2) “The Same Drift Monodiameter Clad/Liner System in Solving Drilling and Well Infrastructure Challenges”, with presenter, Matthew Godfrey, Lead Project Engineer, Enventure Global Technology.

Article

May 2020

In the current market, priorities must be rethought, if the industry is to survive, and the importance of wellbore placement to overall profitability must be recognized. Running solid-state gyro technology for improved wellbore placement is one way to achieve financial and operational goals.

Article

April 2020

Wellbore placement accuracy remains critical to successful offshore operations, particularly where there is a high risk of wellbore collision. Companies implementing gyro technology can mitigate such risks and improve the separation factor between their wells.

Article

April 2020

Operators are using cloud-based well barrier illustrations, with the two-barrier philosophy, as the logical starting point to manage their well integrity and reduce risk.

Article

April 2020

To operate a well is to operate responsibly—but more must be done on sustainable design and balanced portfolios to achieve a net-zero future.

Article

April 2020

Augmented and virtual reality systems reduce rig time usage and mitigate uncertainties, while improving accuracy of rig surveys for offshore solids control and fluid management installations.

Article

March 2020

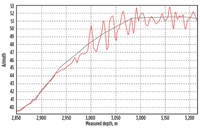

A novel, high-density logging technology illuminates areas of high tortuosity in the wellbore to improve production equipment placement and reduce downhole damage.

Article

March 2020

A hybrid UBD/MPD solution for an unconventional gas exploration project proves to mitigate hazards, improve safety, and make future drilling campaigns economically viable.

Article

February 2020

In today’s environment, the need to expedite wellbore construction has been supplanted by the requirement to drill boreholes more intelligently. A real-time wellbore guidance technology offers operators and service companies a means of improving precision and accuracy in wellbore placement.

Article

February 2020

Improved offshore activity, coupled with significant conventional oil development programs operated by NOCs, should push drilling marginally higher in 2020.

Article

February 2020

As wellbores and drilling operations have become more complex, drill bit development must keep pace to meet increasingly difficult performance requirements.

Article

January 2020

Into the brink

News

January 17, 2020

Oil production in Angola has slumped by a third in the past decade to less than 1.4 million barrels a day, reflecting years of underinvestment in new projects.

News

January 14, 2020

The well in Angola’s Block 48 will be drilled at a new world record water depth of 3,628 m. The current world record is 3,400 m, set by Maersk Voyager’s sister drillship Maersk Venturer when it drilled the Raya-1 well for Total offshore Uruguay in 2016.

News

January 10, 2020

Maersk Drilling has been awarded a contract for the 7th generation drillship Maersk Valiant which will be employed by Noble Energy for a one-well campaign offshore Colombia.

Article

December 2019

The rig is a little taller than the driller, and the bit fits in the palm of his hand. Designed, built and operated by a team of university students, the miniature drilling system is making hole for SPE’s international Drillbotics competition. Their objective is to autonomously drill a directional well to plan, as quickly as possible, while maintaining borehole quality, and integrity of the rig and drillstring.