Automation & Control

Article

March 2021

A wired drill pipe system enables real-time data transmission and sends constant information to decision-makers during drilling and tripping. North Sea case studies demonstrate how combining multiple downhole tool technologies has improved drilling efficiency and prevented various issues.

Webcast

Beyond Automation in Well Construction

March 24, 2021

Schlumberger

Learn how we are taking well construction beyond automation and into autonomy. The great strides that have been made in well construction automation are delivering good results, but the complex and dynamic environment of well construction requires more than automation to deliver consistent performance improvements. Our expert presenters will explain how we are achieving this by maximizing the capability with Autonomous systems, both in rig operations and downhole drilling.

News

February 02, 2021

The initiative provides a framework for energy operators, service providers, equipment providers, and independent software vendors for energy services to offer interoperable solutions, including AI and physics-based models, monitoring, diagnostics, prescriptive actions, and services, powered by the BHC3™ AI Suite and Microsoft Azure.

Article

January 2021

Improve efficiencies, reduce asset downtime and protect critical knowledge with AI-based production technologies.

News

January 14, 2021

Siemens Energy AS and BPT have been successfully working together for the past two years, as part of the Oil and Gas Technology Centre’s ‘Facility of the Future’ study, developing and maturing Floating Normally Unattended Installation technology.

News

January 13, 2021

Following successful six-month operational trials on Stena Spey and Stena Carron rigs, IDS will deploy its data driven TourNet Pro drilling contractor reporting service and drilling performance monitoring service, Anova DPM, across Stena Drilling’s fleet in Q1 2021.

Article

January 2021

Well construction can benefit from available intelligent technologies, taking AI capabilities close to the action, where it encodes knowledge and captures learnings to improve drilling efficiency.

Article

January 2021

A partnership between a drilling contractor and an OFS provider is taking MPD systems, which are fully owned and operated by the drilling contractor, to the next level with unique, integrated capabilities.

Article

December 2020

When a pad well blows out, other nearby wells are in danger of blowout, posing a unique risk. Cascade failures require synergistic use of technologies and specialized expertise to properly respond to, and secure, multiple well blowouts.

News

December 17, 2020

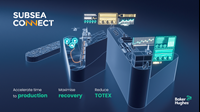

engageSubsea remote serves as an equipment inspection tool, technical support and operational management platform, and is designed to drive operational excellence and increase capital productivity for offshore oil and gas operators.

Article

November 2020

Oil and gas organizations are looking increasingly to embrace technology and improve processes to move further down the path toward transformation in a post-Covid world. To accomplish these objectives will require structure, pragmatism and agility while navigating the road ahead.

Article

November 2020

Operators cash-in near-perfect asset efficiency and long-term value

Article

October 2020

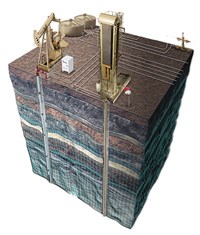

Effective reservoir management requires combining multiple engineering/geoscience disciplines to identify improvement opportunities. To optimize analysis, an AI-powered management platform was developed that delivers faster, more accurate results to maximize asset value.

Article

October 2020

A new solution offers tool-free, 8-min. setup and reduces NPT in multi-well pad operations, thereby yielding more drilling time and lowering costs.

Article

October 2020

Dependable rotary steerable systems, tied to an effective drilling engineering process through digitalization and automation, are the foundation of a new era in directional drilling.

Webcast

Oilfield Automation, Control & Monitoring: Fall 2020

October 22, 2020

M-I SWACO, Aggreko

During this 60 minute live webcast, Moderator, Joe D. Woods, President, International Pinpoint, will lead discussion on these topics: 1) “Digitizing Drilling Fluids”, with presenter, Katherine Price Hoelscher, PhD, Product Champion, M-I SWACO. 2) “Real-time Remote Monitoring Provides Improved Uptime in Oilfield Operations”, with presenters, Jesse Brazier, Remote Operations Center Manager and Joshua Haugan, Business Development Manager – North America Oil & Gas, Aggreko.

Article

September 2020

Pursuing revolutionary transformation will redefine how we work and catapult the oil and gas industry forward

Article

September 2020

Effective management of reservoir sweep, with regard to wellbore influx, is an inherent issue affecting horizontal well lengths. As an active, self-regulating technology, autonomous inflow control devices respond to viscosity changes to choke water and gas more effectively, increasing production and sustainability.

Article

July 2020

An advanced software platform takes a human-centric approach in distilling knowledge from unconventional well data.

Article

July 2020

Our industry requires technological advances during this historic downturn to make well construction and production operations safer and more efficient. But with capital expenditures likely to be severely constrained, where will the money come from? To help bridge the gap, existing digital solutions that require no capex spending can be used immediately to increase efficiencies and deliver improved performance.

Article

June 2020

Each year, the oil and gas industry could save billions in OPEX if just a tiny fraction of the world’s rod-lift and gas-lift wells had the benefit of autonomous optimization.