Sustainability: A collaboration to protect the environment

The African proverb — “if you want to go fast, go alone, if you want to go far, go together” well explains the need for the use of collaborations to address the many complex technical challenges facing today’s emerging CCUS industry. While high capital costs and risks associated with regulatory, legal, and economic uncertainties often drive the formation of some CCUS collaborations, others are driven by the need to allocate technical responsibilities amongst participating parties to overcome a specific set of these challenges.

The resulting sharing of knowledge and experience allows participating companies to expand capabilities and optimize efficiencies without diluting core competencies. As a result, these technically driven collaborations are providing more complete and cost-competitive solutions to help operators overcome complex CCUS challenges.

One such technical collaboration was formed in January 2023, when MicroSeismic Inc. (MSI) and EverAware LLC (EverAware) agreed to share their expertise, knowledge and processes to develop comprehensive subsurface and surface continuous monitoring solutions. These solutions are designed to satisfy the growing need by operators and governments to mitigate environmental risks associated with geological carbon sequestration. The initial goal of the collaboration is to jointly address the Monitoring Reporting and Verification (MRV) Plan requirements defined in Part 98, Subpart RR, of the EPA’s “Mandatory Reporting of Greenhouse Gases Rule 40.”

By combining MicroSeismic’s passive seismic imaging technologies with EverAware’s IoT monitoring and data analytics capabilities, the collaboration provides industry with a turn-key solution that addresses key surface and subsurface MRV requirements. Just as importantly, the services also provide comfort to local communities on the safety of CCS operations, allowing for a continuing social license to practice.

MICROSEISMIC INC. OVERVIEW

MSI is a leading global energy and environmental monitoring service company. The company was founded in 2003, with a mission to bring passive seismic technology to the oil field. MSI’s original vision of monitoring applications included CO2 sequestration, sinkhole detection, enhanced geothermal systems, production and disposal wells, reservoir stimulation, and wellbore stability in tectonically active areas.

Driven by the explosive growth in production from unconventional reservoirs during the mid-2000’s, MSI became the world’s largest independent frac monitoring company, having monitored more than 50,000 frac stages for over 200 companies in 18 countries while maintaining an industry-leading safety record of zero LTI’s for more than 2.5 million hours of field activity.

Since then, MSI has been able to capture much of its early vision by expanding the use of passive seismic technologies into subsidiaries that now provide monitoring of carbon storage (CO2SeQure®) and Enhanced Geothermal Systems (MicroThermal Energy™), as well as early warning of impending sinkhole collapse (KarstAlert®). MSI acquires data in the field, then processes and analyzes that data to deliver meaningful and timely solutions to its expanding client base. MSI and its founders have been recognized by the industry for their innovative technology. Recently, MSI was awarded three grants from the DOE to accelerate development of the CO2SeQure business.

EVERAWARE LLC OVERVIEW

EverAware is a digital transformation service company that utilizes cost-effective smart sensors, meters, gateways, advanced data analytics, and the cloud to continuously monitor operations, equipment, and environmental conditions for detecting anomalous data patterns indicative of performance issues, imminent equipment failures, or fugitive leakage of emissions or liquids. The company’s goal is to provide continuous IoT monitoring solutions to identify potential problems and threats in real time, so they can be addressed quickly to minimize downtime, optimize efficiencies, reduce operating costs, and mitigate damage to the environment by agile, in-situ, carbon emission monitoring.

EverAware was formed in May 2021 as an international venture with South Korea’s Net Zero Holdings Group, Inc., and ulalaLAB Inc. to blend their leadership in carbon neutrality strategy, IoT monitoring and data lake technologies with global upstream operational expertise, to provide cost-effective and continuous user-friendly energy and environment monitoring solutions.

Net Zero Holdings Group, Inc. (NZH), was established in 2004, and is South Korea’s first and front-running investment & innovative solution provider in the energy industry and now acting as a leading Net-Zero industry partner for the South Korean government, local municipalities throughout Southeast Asia, and industry. Howard H.W. Park, the founder of NZH, is renowned for his efforts to help public and private entities manage their energy transitions from traditional fossil fuel-based operations to green renewable energy alternatives, using carbon-neutral energy solutions, including organic waste to biofuels.

UlalaLAB was established in 2011 and is South Korea’s leading intelligent data lake solution provider for industrial IoT devices and sensors, data interface, real-time monitoring, visualization, and ML / AI analytics. They have monitoring installations in 10 countries globally and maintain a goal of assisting individuals and companies to make better decisions and remain focused on the most valuable tasks.

MEETING THE MRV CHALLENGE

The key drivers in forming the collaboration were a shared vision on the use of continuous monitoring to protect the environment and a recognition of the high synergy existing between each company’s data collection, data analytics, and data visualization processes, (Fig. 1). The collaboration was able to exploit the complementary expertise in these processes and optimize the use of equipment, field support, data transmission, data retrieval, data analytics and reporting. The cost-savings resulting from this optimization enable the collaboration to provide turn-key continuous monitoring solutions that are comprehensive, integrated, technically excellent and cost effective.

Subpart RR requires operators of CCUS facilities to submit a proposed MRV Plan to meet the EPA requirements during the project approval process. Such plans must ensure that CO2 injected into storage reservoirs is permanently contained within targeted geologic formations, that it is moving as anticipated in the subsurface, and that any unexpected, induced seismicity, CO2 plume migration or leaks to the atmosphere are detected early, so that appropriate responses can be taken. Approval of the MRV Plan from the EPA is required before the start of field operations, as well as to qualify for the 45Q tax credits associated with carbon storage.

By leveraging their combined capabilities, the collaboration partners have developed industry’s only turn-key continuous monitoring solution that addresses all of the following critical requirements of a successful MRV Plan:

- Confirm the injected CO2 is staying within the target formation,

- Monitor caprock integrity, and identify potential pathways of CO2 leakage,

- Track the CO2 plume, as it grows during the injection process,

- Detect early indicators of escaping CO2 at the surface, within shallow aquifers and from fugitive emissions associated with facilities,

- Ensure CO2 injection rates and pressures do not induce seismicity, thereby mitigating the hazard to local infrastructure.

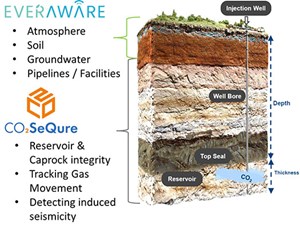

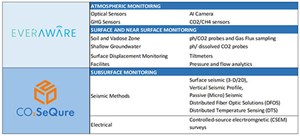

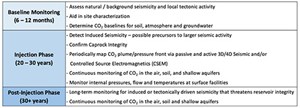

The technical division of responsibilities within the collaboration is shown in Fig. 2. MSI is responsible for subsurface monitoring needs, including tasks associated with determining caprock integrity, tracking the movement of injected gas, and detecting induced seismicity. EverAware is tasked to monitor the environmental conditions in the atmosphere, soil, groundwater, shallow aquifer, and surface facilities.

The challenge of monitoring such a wide array of environmental factors over a large volume of the earth for the decade’s long-life cycle of a sequestration project is not to be taken lightly. Furthermore, the likelihood of near-term regulatory changes and technical innovations within this relatively new industry, as it matures, is high. The technical focus and nimbleness of the partners in this collaboration ensure that their solution will continue to evolve in response to the industry’s needs. The current list of resources in the collaboration’s toolbox is listed in Table 1. While there is a clear delineation of services to be provided in this list, the sharing of resources within the Collaboration provides clients with a seamless and fully integrated monitoring product.

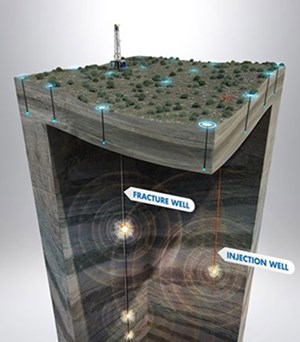

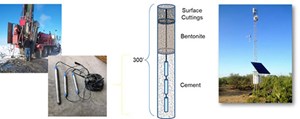

MicroSeismic’s subsurface monitoring solutions are contributed through its subsidiary, CO2SeQure and uses their BuriedArray® technology to provide continuous monitoring throughout the lifecycle of a CCUS Project. As illustrated in Figs. 3 and 4, multi-component geophones are permanently cemented in shallow (usually <300 ft) boreholes, spaced at intervals that are custom designed for each project. Each buried array station is equipped with telecommunication devices that collect and transmit the data to a central processing facility for real-time analysis. The recording and telecommunications hardware is powered by wind and solar, and it functions autonomously, except for semi-annual maintenance visits.

The array is installed before the start of CO2 injection to calibrate baseline ambient seismicity in the area. Once injection begins, the continuous data stream is analyzed by an AI-driven algorithm to detect microseismic events indicative of caprock failure, or slippage on regional faults that could lead to larger magnitude induced seismicity. A “stoplight system” is established to automatically notify the operator when events surpassing certain critical levels of magnitude, frequency or location are identified. MSI has installed and operated 75 BuriedArray® systems over the last 12 years for a variety of geotechnical objectives.

EverAware’s environmental surface monitoring solutions (Fig. 5) utilize IoT-based installations that include the necessary sensors and probes for evaluating conditions in the atmosphere, the soil, and shallow freshwater aquifers. Wireless CO2 detectors are used for monitoring the atmosphere, while dissolved CO2 and pH probes are used for monitoring groundwater. The soil is monitored, using sensors that identify changes in properties, such as pH that reflects local acidization, due to CO2 contamination. AI cameras are also available for providing continuous visual monitoring of field activities around key surface facilities.

The use of IoT Plug & Play technologies enables these installations to adapt readily to changes in field conditions, changes in government regulations or advancements in technologies that will certainly occur during the life of a CCUS Project. As such, the surface monitoring installations are not static and can quickly and easily adapt by simply adding or removing sensors, meters, or gateway devices. This flexibility also allows the geometry of the monitoring installation to be modified in response to increased hazards identified by MicroSeismic’s subsurface observations.

An example of EverAware’s environmental monitoring system is shown in Fig. 6. This installation is measuring critical chemical properties in an aquaculture pond. The equipment here will be integrated into and co-located with the MSI equipment as pictured in Fig. 4.

GROWING THE COLLABORATION/ EXPANDING CAPABILITIES

To help the collaboration maximize the effectiveness of their monitoring technologies, MSI and EverAware have entered an agreement with the Climate Change Research Division of the Korea Institute of Geoscience and Mineral Resources (KIGAM). As South Korea’s unique government-funded geoscience research organization, KIGAM has contributed to resolving public safety issues as well as to national developments since its foundation as the Geological Survey of Korea in 1918.

Today, KIGAM pursues innovations and the convergence of pioneering technology to achieve world-class research and create new technologies. To achieve carbon neutrality, the Climate Change Response Research Division is conducting research in the use of large-scale offshore CO2 storage facilities, including developing key technologies associated with CCS deployment.

The parties will jointly share research associated with monitoring technologies and will secure test sites for product development. The technologies to be studied focus on the use of microseismic solutions, including fiber optics, groundwater protection, digital transformation, and artificial intelligence.

SUMMARY: A CONTINUOUS MONITORING SOLUTION FOR A CCUS PROJECT’S LIFE

Within their collaboration, MicroSeismic and EverAware have worked together to develop MRV solutions that meet the requirements, as defined today, and are positioned to expand their capabilities to include advancements in technologies to satisfy the MRV needs of tomorrow. By optimizing efficiencies and sharing support infrastructure, their products reflect the cost-savings created by the collaboration. In addition to protecting the environment by providing a full life-of-project CCUS monitoring solution, as outlined below in Table 2, the company is also well-positioned to provide preventive carbon emission maintenance through early leak detection solutions that address the methane emissions regulations included in the Inflation Reduction Act of 2022.

All in all, this collaboration is further confirmation that by going together, you really can go far!

- Coiled tubing drilling’s role in the energy transition (March 2024)

- Advancing offshore decarbonization through electrification of FPSOs (March 2024)

- Executive viewpoint: TRRC opinion: Special interest groups are killing jobs to save their own (February 2024)

- Energy Addition is what’s required (December 2023)

- Buddy, can you spare a credit? (December 2023)

- Digital transformation: Accelerating productivity, sustainability in oil and gas (November 2023)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)