Engineering and upscaling of new floating wind energy platform

These challenges are expected to be solved mainly through the following factors: 1) development of an industrialized fabrication system (prefabricating technology) for mass production; 2) design optimization from real experience data against the values obtained through conservative calculation; 3) optimization of operations and maintenance logistics through data collection and analytics of real experiences of the open-sea operation of the DemoSATH 2MW prototype; and 4) internationalization of technology through branches in markets with high floating wind potential, Fig. 1.

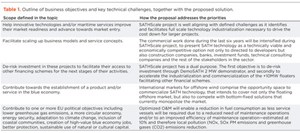

Scope of work. The SATHScale proposal was presented by Saitec to the European Commission (EC) under the call, “EMFF-BEW-2019: BlueInvest Grants: Investing in blue innovation of the blue economy window call. The specific challenges define the objective of developing and bringing to market new products, services, and business models for SMEs that could ultimately create profitable activities, Table 1.

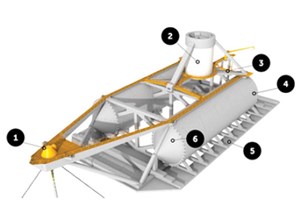

SATH technology concept. SATH floating platform is based on four fundamental principles: 1) the use of concrete; 2) the geometry of the floats; 3) the arrangement of the structure; and 4) the mooring system. If implemented properly, these innovations will offer the following competitive advantages, compared to other existing products in the market: 1) the use of concrete instead of steel to reduce the construction, operation and maintenance costs, as well as to extend its operational lifetime; 2) the construction and assembly are made entirely onshore, which reduces both investment costs and potential risks (e. g. labor, HSE, and weather windows) and towing the assembly floating to site; 3) platform draught is reduced (draught <10 m), which makes it suitable for both shallow and deep waters; 4) it provides a plug-and-play solution, with an easy connection process, so the platform can be easily installed or disconnected and taken ashore for major part repairs; and 5) it includes a single-point mooring system, which allows the platform to rotate like a weathervane facing the wind. This helps the yaw control system of the wind turbine and reduces the stresses on the mooring lines.

The main advantages of this solution over the existing, installed floating prototypes lies mainly on the following three points: 1) the use of concrete, which involves costs-savings against steel; 2) excellent resistance to extreme sea conditions; and 3) less maintenance required. SATH technology is based on the efficient use of concrete, which also provides four significant advantages:

- Reduced cost material solution, compared to steel

- The use of concrete instead of steel results in lower maintenance costs

- An adequate concrete design ensures durability significantly, extending the life of the platform well beyond what would be obtained by using steel

- Supports local content for the construction of the platform.

Thanks to the innovative single-point mooring system (Fig. 2), the efforts and required resources in the mooring lines are reduced (1). In addition, the platform, itself, is installed where it can turn to line up, to benefit from the best wind resource at the moment. The floaters have a cylindrical geometry, with an ovoid section allowing the reduction of thrust forces on the structure. This permits the draft to be small, enabling its installation and operation in a wide range of water depths. This second principle is related to the geometry of the floaters. These floaters have a cylindrical geometry, with an ovoid section that allows a dramatic reduction of the concrete shell thickness and therefore weight of the platform (4). This allows obtaining a reduced draught, enabling the platform to be installed and operated in a wide range of water depths. The arrangement of the floaters in the structural assembly (3) is also part of this second principle. The floaters orientation, both in parallel like a catamaran, provides the stability to adapt to adverse wave conditions. It is important to remark the role of the stabilizing plates (5) that are located at the bottom of the platform below water level. By taking advantage of the added mass of water due to these plates, the natural periods of oscillation of the platform are detuned from those of the sea waves. This way, motions are reduced to levels suitable for the correct operation of the wind turbine. Other considered parts are the hybrid (concrete + steel) transition piece (2) and the conical caps of the floaters (6).

SATH platform uses, as station-keeping, a single-point mooring (SPM), Fig. 3. This anchoring system, also used in the oil industry, allows the platform to rotate freely around this single point, as a weathervane, reducing the environmental forces on the platform and therefore the cost of the mooring. Besides, this helps the yaw control of the turbine to orientate the rotor plane against the wind. This principle is one of the main advantages of the SATH solution, clearly differentiating its greater value, compared to its competitors.

Cost reduction. An important reduction of costs, compared to other systems, will allow the reduction of the LCoE. SATH has a clear objective in optimizing the costs of the platform construction from the first stages of its development. The new SATH solution will have a global focus considering all sides: economic and technical. The significant cost reduction will break the market and mark a new way of energy production. In order to quantify and demonstrate the mentioned costs reduction, SAITEC recently contracted with BVG Associates for an independent assessment on the LCoE of different foundation technologies (monopile, jacket, semisub, spar and SATH). Comparing SATH to bottom fixed solutions, at 25 m the capex is similar to a monopile and SATH actually beats jacket on capex at a depth of 45 m. Furthermore, when compared to other floating technologies, SATH provides a capex reduction between 40% and 50%, which produces a reduction of LCoE of more than 10%. As a consequence, in the target market (sites with depths of more than 30 m) SATH technology can achieve a leader position.

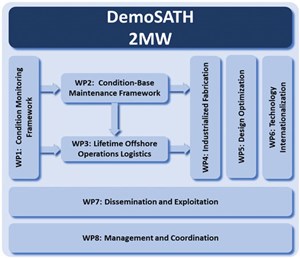

Methodology. The overall methodology is in connection with the project’s technical objectives and has been divided into clearly defined work packages that reflect the processes and practical issues. Completion of work package tasks and milestones will combine to ensure that the project reaches a successful conclusion. The project is structured in six Work Packages, including one completely devoted to “Management and coordination” and another one to “Dissemination,” including dissemination and communication activities. Figure 4 illustrates the principle behind the design of the project implementation stages, following the natural progression of a development process.

Challenges and solutions. To make floating offshore wind cost-competitive with other energy sources, large volumes of floaters need to be produced and installed. The priority is to develop the floating design that offers best value for money. A design that performs well and can be easily mass-produced at low costs. Saitec has developed the SATH floating wind turbine solution. This new technology represents a disruptive change over current floating solutions due to the use of different construction materials (concrete instead of steel). The single mooring point and the versatility of the design that makes it adaptable to very different depths of water. Thanks to these characteristics, once implemented at commercial scale, it will allow a reduction in LCoE not only over the current floating technology but also over the fixed bottom offshore wind solutions.

DemoSATH platform (ongoing project). Although the construction process was delayed, due to the pandemic, the original planning started in September 2020 and was set for launch in mid-2021. The project is ongoing and expected to be ready for float-off—tentatively—at the end of April 2022. Figure 5 shows the ongoing construction activities of the DemoSATH Floating Offshore Wind Turbine, at the Bilbao Port facilities in the North of Spain.

Innovation potential. SATHScale proposes an innovative and mature offshore wind turbine concept to meet the objectives and scope defined in the present Blue Economy window call. It is an innovative project in the offshore market in relation to two fundamental aspects: 1) a disruptive floating platform technology in terms of market technology; and 2) technological leap within the SATH technology itself, since it will integrate: a) SATH floating foundation easily scaled-up for 10MW and larger turbines with a reduced CAPEX increase. SATH design is based on a modular division of the platform structure; b) standardization of transport methods and assembly and c) risk reduction is a key element when accessing the financing necessary for the development of this type of technology.

The full integrated concept will contribute to market entry of floating offshore wind energy and to meet the targets set by S.E.T plan in terms of installed wind energy capacity and cost.

Competitive advantages. SATHs support structure capex is, at least, 45% lower than semi-subs or SPARs. SATH is the only technology that is feasible for all water depths: shallow (25 m), deep (>25 m and up to 45 m) and very deep (>85 m), Fig. 6. SATH offers the most competitive LCoE for floating offshore wind projects in water depths of 45 m and deeper.

Market opportunities. According to various sources, estimates stand that an offshore potential wind capacity of more than 10,000 GW is available, just considering Europe, U.S. and Japan. From all of this potential, approximately 80% is located in zones where water depths exceed the maximum feasible depth for bottom-fixed solutions. In other words, offshore floating wind potential in those three regions comes to 7,000 GW.

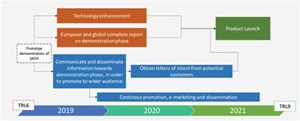

Growth. The commercialization strategy brings together the various aspects presented throughout this proposal and highlights the links between the various tasks which nerequired to bring SATH from TRL 6 to TRL 9, Fig. 7. The color code serves to differentiate between commercial tasks (blue), technical (orange) and sales (green).

SAITEC, established in 1988, is an important Spanish engineering firm with a strong innovative vocation and 230 employees. SAITEC wants to position itself in the offshore wind energy sector and it is under this premise that SAITEC has identified the business opportunity provided by the SATH platform in a market that is currently in an emerging phase, not mature, and in which SAITEC sees the opportunity to build on its internationalization process. In 2016, SAITEC Offshore Technologies was created as a spin-off company of SAITEC, with the aim to develop the wind energy market.

It has become an independent company, owning all developments to date. Therefore, SATH project is the backbone of the company, and all the resources are devoted to this project. SAITEC Offshore participates in the Toyoura wind farm, in Japan, with 10% of the shares. In a similar way, and showing the huge interest that the Japanese market represents, Saitec Offshore has already created a subsidiary company in Japan (Saitec Offshore Japan KK). SAITEC Offshore will cover the entire value chain to design the prototype, manufacture, assemble, commission, validate and test technologies.

Key partners and the path forward. Saitec Offshore is working with several Japanese partners on a proposal for an R&D project in Japan this year, focused on the certification of concrete barges. According to ClassNK, Saitec Offshore closed on Feb. 18, 2020, a collaboration agreement with RWE, world’s second biggest offshore wind developer. This collaboration agreement provides significant commercial opportunities for Saitec Offshore. It should be noted that RWE is earmarking €1.5 billion a year for investments in green energy. This collaboration agreement offers significant commercial opportunities for Saitec Offshore. Furthermore, this close collaboration also provides the possibility for Saitec Offshore to capture a massive market share. The company has signed several MOUs including:

- MOU with Worley to promote, collaborate on, and deliver offshore wind projects employing SATH technology.

- MOU with Steelite to form a JV to supply a floating system in India and initially develop a 3-MW prototype.

- MOU with Shinobuyama Fukushima Electric Power to develop a floating offshore wind firm project in Japan.

- An agreement with Taifung to be Saitec Offshore’ s commercial agent in Taiwan.

- An MOU with Univergy to develop a 400-MW wind farm in Toyoura.

- Agreement with Pacific Steel Supplies to develop projects in the Pacific Islands

- Coiled tubing drilling’s role in the energy transition (March 2024)

- Advancing offshore decarbonization through electrification of FPSOs (March 2024)

- Subsea technology- Corrosion monitoring: From failure to success (February 2024)

- Executive viewpoint: TRRC opinion: Special interest groups are killing jobs to save their own (February 2024)

- Driving MPD adoption with performance-enhancing technologies (January 2024)

- Digital transformation: A breakthrough year for digitalization in the offshore sector (January 2024)