Digital solutions for subsea pipelines, cable protection and life extension

Digital technology development continues at a rapid pace in our personal lives and business environments. This transformation is increasing functionality and accessibility while creating significant gains in productivity, efficiency and visibility, and enhancing the decision-making process. With growing competition in energy markets, and more demanding field development conditions, the offshore oil and gas industry is investigating new digital solutions to increase efficiencies throughout a field’s lifetime.

Subsea pipelines and cables are critical infrastructure. Their continued reliable performance is essential to avoid costly repairs, replacement or even premature abandonment. Digital solutions that provide insight through continuous monitoring can address existing design validation and performance assurance challenges, presenting new opportunities for integrity management of these vital assets and the realization of new operating efficiencies.

CHALLENGES AND OPPORTUNITIES

It is estimated that over 100,000 km of oil and gas pipelines and cables are in service, in subsea operations. In today’s low-price environment, operators need to extend the intended design life to maximize asset value and return on investment.

For new offshore developments, performance demands on subsea pipelines are growing, as the industry increasingly relies on cost-effective solutions, such as long tie-backs between new reservoirs and existing offshore production facilities. In both brownfield and greenfield applications, if the key factors impacting the integrity of these pipelines can be monitored, they provide operators with extremely valuable visibility, enabling knowledge-based decision-making on several aspects, including: 1) reliability and safety; 2) operational parameters; 3) risk mitigation; and 4) life extension and inspection frequency. The goal of all these initiatives is to reduce capex and opex.

The key factors driving the design and longevity of a pipeline or cable can vary, depending on its installation and service conditions. For example, if the pipeline or cable is being used in dynamic applications, such as for riser sections or flowline spans, then measuring motion and bending would quantify load and fatigue exposure, giving a realistic appreciation of the safety factors and system longevity. Similarly, if the pipeline is transporting corrosive or erosive materials, then measuring wall thickness degradation over time would also enable predictions of life expectancy.

Typically, the design and service performance of subsea pipelines and cables has, for the most part, been verified by ROV/AUV surveys and pigging, in accordance with planned service schedules. These functions provide a snapshot of the condition of the pipe or cable but offer limited measurable data, only providing a single point of reference of what is happening, as opposed to a motion sensor that can provide millions of data points.

Based on the levels of determined risk per pipeline, cable or per field, without the vast array of data points provided by a motion sensor, operations teams will need to set increased survey and maintenance schedules. This is a significant commitment in terms of cost considering the vessels, ROV and survey equipment required for deployment each time. In the case of pigging, this also can include a potential need for permanent field infrastructure to be installed for pig retrieval.

While continuous monitoring of key factors would provide the insight to enable operators to gain reassurance or make informed decisions in relation to integrity management, it has not yet become commonplace on subsea pipelines and cables. Historical, negative experiences of users include difficulty attaching and deploying the necessary hardware; limited battery life; data inaccuracy; and the overall cost of monitoring hardware.

NEW APPROACH

Recognizing the value that monitoring provides, Trelleborg’s offshore operation is applying the firm’s in-depth knowledge of pipeline and cable protection in harsh dynamic conditions. The aim of the R&D initiative is to address the challenges limiting wider accessibility and adoption of monitoring on subsea pipelines and cables in critical locations, by simplifying ROV installation and increasing reliability and endurance.

The analysis yielded a new approach to pipeline and cable monitoring, by developing innovative digital observation technology. The new systems can be integrated into nearby ancillary protection products, such as bend stiffeners or buoyancy modules, or attached via a stand-alone clamp system, negating the need for specialist support. Its goal at the outset was to engineer reliable, cost-effective sensing technologies that are easily accessible, deployable and recoverable, containing data that are then validated and processed.

Aligned with Trelleborg’s existing protection technologies and application areas, the initial monitoring solutions are part of the Mimir Digital Intelligence product line. They are specifically designed to capture data on motion and bending strain, which commonly cause damage and fatigue to pipes and cables in subsea environments, including:

- Vortex-induced vibration caused by current flow.

- Slug-induced vibration created by variations in density of production fluid flow.

- Dynamic risers connecting to floating platforms, particularly toward topside terminations and touch-down points.

- Axial walking and buckling on HPHT flowlines.

- Pipeline and cable seabed stability.

CASE STUDY

In 2017, Trelleborg’s offshore operation collaborated with a major operator to develop a solution to monitor motions of an existing flowline experiencing intermittent vibration. It was apparent from ROV surveys, that the motion was detrimental and presented unforeseen risk to the operator. Unfortunately, due to its intermittent nature, the extent of motion was difficult to quantify, as the ROV could only provide a snapshot in time.

Complex flow assurance and finite element analyses were performed to model the phenomena. However, there were still uncertainties, leaving the operator with the decision of whether to slow production, add mitigation methods, and increase ROV inspection frequencies and durations. The challenge presented an opportunity to apply a novel, cost-effective approach.

Technology development. To solve these issues, Trelleborg’s engineering team retrofitted Mimir Motion Clamps onto the flowline, to continuously record pipe motion data for subsequent processing and analysis. As the pipeline motion was difficult to predict, it was important to have sensors capable of accurately recording data over a wide range of amplitudes and time periods. By working with advanced micro-electromechanical systems (MEMS) sensor technology, and validating data through testing, application requirements were identified accurately.

There was a unique requirement for longer battery life (5+ years) to support continuous monitoring, to ensure that the required sensor performance and sampling rate were met. The manufacturing team was charged with keeping the electronics and battery module as compact as possible. In this application, the requirement to measure small movements of the pipeline increases sampling rate and power usage, altering the approach to data logging and communications. Due to the wireless bandwidth constraints subsea, and the complexity of motion algorithms, which place a high demand on power usage, full data capture and physical recovery were the most efficient solution.

The clamp design was also a key consideration. The application would require ease of installation, using an ROV, as well as consistent clamping force throughout the service period. After service, the device would have to be recovered without sustaining damage, to enable the technology to be used repeatedly.

Calling on their existing pipe clamping experience and product knowledge, Trelleborg’s offshore operation worked closely with ROV operators to specifically develop a cost-effective clamping arrangement, to reliably perform this function. The motion clamp’s general arrangement and key features are presented in Fig. 1 and below:

- Advanced sensor technology - Modularly reconfigurable circuit board array with over 20 advanced sensors, capable of monitoring all pipeline motions and strains, incorporating a wide range of use applications.

- Independent, extended life - Designed as long-lasting, battery-powered monitoring units, capable of monitoring beyond five years, due to built-in selection of low-power electronics and cutting-edge, industrial MEMS sensors.

- Simplistic installation and removal - The motion clamp has been designed for attachment and removal by work-class ROVs, being affixed easily to the pipeline by a manipulator jaw in a single “locate-and-rotate” actuation.

- Attachment assurance - Reliable attachment to the pipeline was vital to ensure that the clamp stayed locked in position under all design conditions, for the data recording to maintain a firm datum. Engineers applied existing clamping knowledge, considering variable parameters, such as expansion, contractions, creep of coatings, temperature range, loadings and motions in the design.

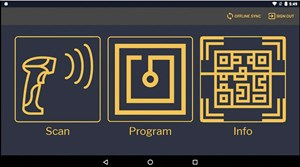

- Workflow-based app - All clamp communication; operational documentation, including visual installation documents; material information; design assurance; and factory acceptance testing were digitally provided to the operator directly with the Mimir Digital Technician App, Fig. 2. The device eliminated the need for an engineering specialist to be present.

- Electronic module pressure vessel - The pressure vessels protecting the electronics hardware were provided with safety and longevity in mind. The design also allowed repeated reuse to enable future swap-out of batteries and upgrade of the modular electronic boards.

Development of the motion clamp took place over six months, with several units deployed onto the pipeline within 12 months. Data from the first deployment have since been recovered and processed by the service provider’s offshore operation, in open collaboration with the operator. Results, so far, have proven insightful, enabling the operator to decide the next steps.

FURTHER DEVELOPMENTS

Since this application was first introduced, Trelleborg’s offshore operation has further developed the performance and functionality of their Mimir Digital Intelligence monitoring devices, to include ROV hot-swappable electronic modules. This allows the operator to retrieve the sensor or data only, negating the need to recover the entire clamp. Other developments include the further integration of Mimir Digital Intelligence technology within the existing product portfolio, while increasing the sensor portfolio and use cases.

SUMMARY

By increasing the accessibility, reliability and cost-effectiveness of subsea monitoring, these systems can become more widely adopted within the oil and gas industry, leading to insights and intelligent data, which can increase ROI by enabling life extension of the field. The increased knowledge generated from sensors enable operators to fine-tune systems and processes, with higher-quality data and information.

Furthermore, their deployment can reduce the high opex costs associated with current ROV surveys. The data gathered provide key performance insight and modelling capabilities to support subsea asset integrity management, realizing value and carbon reduction opportunities through design, increased operational efficiencies and field life extension.

- The evolution of remote-controlled FPSOs (January)

- How AI-driven asset management is channeling the sea of data into actionable insights for companies (December 2025)

- Upstream benefits: Oil and gas networks for the digital era (December 2025)

- Comprehensive cybersecurity approach protects the heart of the rig (December 2025)

- Transforming challenging well production through advanced engineering (December 2025)

- Oil and gas in the capitals: Norway sustains the industry (December 2025)

- Subsea technology- Corrosion monitoring: From failure to success (February 2024)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)