Completions

News

February 18, 2025

Zion Oil & Gas announced a significant operational milestone as work resumes on the recompletion of the Megiddo-Jezreel 1 (MJ-01) well in Israel. This marks a crucial phase in Zion’s ongoing efforts to unlock Israel’s onshore energy potential.

News

January 13, 2025

Atlas Energy Solutions Inc. announced the first commercial delivery of proppant sand from its Dune Express conveyor system in the Permian basin. Proppant is a necessary component in recovery of hydrocarbons from oil and natural gas wells.

News

October 23, 2024

(WO) — BiSN, the global provider of wel-lok™ sealing solutions, has achieved a significant milestone by reaching 500 commercial deployments of its bismuth-based sealing technology.

News

September 20, 2024

The addition of Flex Orbit to the EPIC product portfolio combines the open-architecture benefits of the EPIC Flex system with advanced self-orienting capabilities for precision shot placement at any desired angle or orientation for enhanced well productivity.

News

September 17, 2024

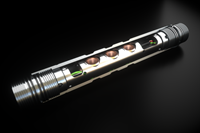

The Clear portfolio includes: ClearTrac wireline tractor; ClearCut non-dangerous goods electromechanical pipe cutters; and, coming soon, ClearShift high-expansion shifters to open and close downhole valves that include barrier isolation devices.

News

August 29, 2024

This collaboration enables E&P companies to seamlessly access TGS' licensed production, completions, and cost data via the ComboCurve platform, with fully automated data integration that requires minimal technical infrastructure.

News

July 26, 2024

Adena Power has joined Halliburton Labs, marking a new collaboration aimed at advancing energy storage solutions.

Article

July 2024

By combining RFID technology with premium packer performance and exceptional safety valve reliability, gas-lift wells can be operated with the highest safety standards for the life of the well, in the latest advancements in Annular Safety Valves (ASVs).

Article

May 2024

A unique collaborative approach to completions management demonstrates how working from a different perspective can optimize operational efficiency and improve well economics.

News

May 29, 2024

Weatherford will offer its Accuview downhole monitoring solutions with the AlphaVTM next-generation whipstock system. Notably, in 2023, Weatherford successfully introduced AlphaVTM, enabled by the Accuview platform in the North Sea for Equinor.

Article

May 2024

Far too many companies are seemingly holding back on utilizing horizontal wells to access Enhanced Geothermal Systems and risk missing a golden opportunity to extract heat from the Earth’s crust.

Article

May 2024

As fracturing intensity continues, operators are looking for additional ways to increase efficiencies. One such solution is automation in the fracturing process. Accordingly, a platform of digital software controls and hardware enables operators to pursue automation, while executing completions safely and more efficiently.

News

May 13, 2024

Patterson-UTI expects to hold a minority equity interest in Turnwell Industries LLC OPC, a company recently formed by ADNOC Drilling. Patterson-UTI expects that Schlumberger Middle East SA, a subsidiary of SLB, will also hold a minority equity interest in Turnwell.

News

May 02, 2024

The company, serving as operator with a 75% stake alongside ONHYM at 25%, has initiated drilling at the Gaufrette prospect with the spudding of the RZK-1 well.

Article

February 2024

In the fast-paced world of upstream oil & gas data, innovation and a relentless focus on continual improvement is not a choice but a necessity.

News

February 13, 2024

The acquisition of Coretrax will enable Expro to expand its portfolio of cost-effective, technology-enabled well construction and well intervention & integrity solutions, particularly across the North and Latin America, Europe and Sub-Saharan Africa and Middle East and North Africa regions.

News

January 24, 2024

An innovative cloud-based platform was developed to align all disparate data sources from a completions site into a unified, contextualized stream for real-time access, analysis and optimized reporting.

Article

December 2023

An innovative cloud-based platform was developed to align all disparate data sources from a completions site into a unified, contextualized stream for real-time access, analysis and optimized reporting.

News

October 20, 2023

The total includes 709 to drill new oil or gas wells, 10 to re-enter plugged wellbores and 80 for re-completions of existing wellbores.

News

October 03, 2023

Through an innovative combination of stimulation capability and through-completion selective intervention, the FlexRite Selective Access system delivers life-of-well versatility to multilateral installations.

News

October 02, 2023

This first-of-its-kind device addresses reservoir fluid uncertainties and allows the operator to enhance oil and natural gas recovery in wells where current autonomous technologies are limited.