FPSOs, reliability and gas turbine air intake filtration

PETE MCGUIGAN, Filtration & Energy Solutions Division, Parker Filtration Group

Even while forecasts suggest that peak oil may occur by 2030, a clear production boom is underway in key markets, such as Brazil. bp’s recent discovery at the Bumerangue prospect, in Brazil’s deepwater Santos basin, marks its largest find in over two decades. It is a significator indicator of the ongoing global demand for oil and gas.

However, as in bp’s case, the market is characterized by the development of fields that are moving steadily further offshore and into ever-deeper waters. Consequently, the application of Floating Production Storage and Offloading (FPSO) vessels is now central to continued fossil fuel production in the region.

Although the Brazilian oil and gas sector is dominated by state-owned oil major Petrobras, other operators also continue to place orders for FPSO vessels, for use in the Brazilian market, Fig. 1. Recently, for example, Shell Brasil contracted for an FPSO vessel for the Gato do Mato oil field—located some 200 km (124 mi) south of Rio de Janeiro— from Japanese firm MODEC. To be moored in a 2,000-m (6,562-ft) water depth, the FPSO, once operational, will be capable of producing some 120,000 bopd, as well as significant quantities of associated gas. It will be the 19th FPSO to be developed by MODEC for the Brazilian market and the second delivered to Shell for operation off Brazil.

Operating FPSOs far from shore presents several unique challenges for owners and operators, where the remote location places even more emphasis on equipment reliability. For example, the MODEC Gato do Mato vessel, which is currently under construction, has a 25-year design life. Onboard equipment will, therefore, also need to have a similar operational lifetime.

One of the most critical pieces of machinery on an FPSO vessel is the gas turbines that provide mechanical drive for compressors and pumps, as well as providing electrical power when coupled to a generator. It is, therefore, clear that considerable design weight must be placed on ensuring turbine reliability. Central to turbine reliability is effective combustion air intake filtration.

THE FPSO AIR QUALITY CHALLENGE

The marine environment is extremely harsh for the high-precision advanced gas turbines that provide critical power and mechanical drive for FPSO vessels. Gas turbines ingest huge volumes of air and any airborne contaminants that find their way into the delicate internals represent a significant operational issue.

The salt (NaCl and KCl) that is found airborne in the marine environment, having been churned up from the sea, is particularly challenging, and it is no exaggeration to call salt a turbine killer. When salt is in a liquid phase, it can stick to turbine blades but will also attract and adhere to other contaminants like dust and grit that are found in the airstream. This process can generate sticky mud-like substances that can clog filter media and rapidly increase the system pressure loss, delta P, reducing efficiency and increasing heat rate.

Any contaminant migrating through the filter and getting downstream can adhere to the GT compressor blades, rapidly diminishing aerodynamic performance and again impacting the efficiency of the asset. Certainly, any drop in efficiency has a cost implication, but reduced efficiency also implies a substantial increase in carbon emissions, an area of increasing concern for the operators of oil and gas production equipment. In addition, a drop in efficiency potentially represents imminent downtime. When turbine internals are contaminated, eventually an offline wash cycle to help restore lost performance will be necessary. In demanding FPSO applications, even short periods of downtime can add up to millions of dollars of lost production.

Beyond issues associated with fouling of the compressor blades, salt—as we all know—is extremely corrosive, and this can cause even more serious issues for an FPSO operating far offshore, possibly affecting components in the hot gas path, such as combustors and the power turbine. Because the worst effects of corrosion often take place deep inside the Gas Turbine, its effects may not be evident in monitored performance data until a component actually breaks. Such an event is catastrophic and might see a machine offline for weeks while any necessary spare parts and service personnel are located and shipped to a vessel that may be hundreds of miles offshore.

Airborne particulates also raise the threat of erosion of the turbine internals. Although this is perhaps less of a challenge far offshore, it can nonetheless create problems with loss of efficiency and premature failure of components. Similarly, hydrocarbons from flaring, for example, although less of an issue now, due to a reduction in the amount of gas flared aboard a typical FPSO today, still raise the concentration of potential contaminants in the air. Again, such materials can be ingested deep within the machine and cause significant operational issues.

For FPSOs, exposure to salt-laden sea spray and water coming from rain, mist, fog, or even high humidity is a key concern, but any materials that can find their way into the GT internals are sure to be problematic. The solution to these issues is effective air intake filtration.

DELIVERING EFFECTIVE FILTRATION

To ensure long-term performance, efficiency and longevity of an FPSO-deployed gas turbine, a filtration system needs to defend the turbine from both liquid and solid phase contaminants while restricting airflow as little as possible. Any pressure drop associated with the necessary protection introduced by the filterhouse and air intake components comes at a cost in GT performance. When designed correctly, however, this is more than counter-balanced when considered against the lifelong reliable performance of a protected machine.

The scale of this design challenge cannot be underestimated, though. Because of its hygroscopic nature, salt absorbs moisture readily and can switch between liquid and solid phases quite easily with changes in ambient relative humidity. A filtration system, therefore, needs to prevent both solid and liquid material entry to the GT, as well as manage the seasonally varying concentrations of the airborne material challenge, the size distribution of this challenge, as well as the continuous changes of state (liquid to solid and vice versa) associated with this contamination. For marine applications like the FPSO, preventing salt ingress is critical, and this precludes allowing any water to travel downstream.

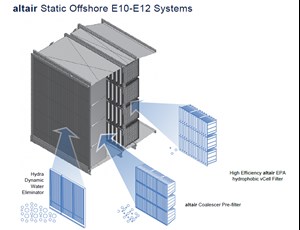

By adding multiple filtration stages, including salt protection and the use of hydrophobic filtration materials, it is very important that the solution considers the increases in pressure drop across the filter sections.

FPSO installations also face additional challenges associated with the lack of available real estate onboard such vessels. For this reason, turbine islands for FPSOs are always designed to be as compact as possible, and the air intake filtration system, as well as all other turbine ancillaries, must adopt a similar design strategy. Baker Hughes is a major provider of gas compression trains for offshore oil and gas production in Brazil, and its SeaSmart offshore packageTM is a high velocity, high-performance filtration system that manages to deliver appropriate air quality while also recognizing the extreme limitations of space onboard FPSOs for the turbine intake system. Parker Hannifin works in partnership with Baker Hughes, supplying the complete filter houses, as well as the filter elements for its SeaSmart turbine packages.

Recently, for example, first oil had been produced from MODEC’s FPSO Bacalhau, which uses Baker Hughes SeaSmart technology, located in the giant pre-salt region of the Santos basin, approximately 185 km (115 mi) off the coast, in the state of São Paulo, Brazil. Under an umbrella contract with Baker Hughes, Parker Hannifin Altair is responsible for the design and manufacture of the complete air intake filtration system, ensuring the reliability and performance of these advanced gas turbines, Fig. 2.

Parker Hannifin’s products have been serving the offshore oil and gas sector for many decades, and the performance of the various filtration system elements is built on a comprehensive testing regime. This is based on subjecting designs to real-world conditions including salt-laden water; fog and mist testing; heat ageing; acoustic testing; and much more, evaluating and improving performance characteristics, such as dust holding capacity and reducing pressure loss through expert application of aerodynamics and ongoing investment in R&D. Even the build quality and the effectiveness of edge sealing to prevent any air bypass has a part to play in maintaining turbine performance and health for an extended service life.

For FPSOs operating in a hostile environment far from shore, performance can never be compromised; the financial risks are simply too high. Choosing the right filtration system means there is one risk operators do not have to worry about.

Related Articles- Oil and gas in the capitals: Norway sustains the industry (December 2025)

- Engineering for the deep: Human support and rescue systems (November 2025)

- Engineered components are the difference between survival and failure in HPHT subsea systems (November 2025)

- Overcoming extreme challenges: Advanced chemical solutions for offshore oil production integrity (September 2025)

- First Oil: Subsea shuttle/Safe Marine Transfer’s equipment showcase brings subsea innovation front and center (September 2025)

- Full-scale test rig validates benefits of electric BOP (August 2025)

- Subsea technology- Corrosion monitoring: From failure to success (February 2024)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)