ShaleTech Report: Tuning unconventional reservoir performance with geoscience-guided completion strategies

In the appraisal phase, unconventional operators diligently acquire core samples and comprehensive log suites in vertical wellbores. Their goal is to select optimal target zones for landing lateral development wells. Very quickly, it is time to drill the first lateral, test the planned completion design, and prove the acreage. Few operators pause at this point to take measurements in the lateral, other than the obligatory measurement-while-drilling gamma ray, and perhaps a mud gas log. Consider a scenario where production is underwhelming: was the completion design suboptimal? Or did the lateral land in a less than optimal formation?

Alternatively, considering the success case, one might ask, did they nail the completion design? Or did they just get lucky with the geology? A common way to answer this is to construct more wells following the same blueprint and measure the average performance of the group to remove the influence of local geological variations.

Data acquisition challenge. The lack of hard data at this critical juncture represents a major missed opportunity to shorten the learning curve and boost project net present value (NPV). Forward-thinking operators acquire comprehensive datasets before, during and after stimulating the first lateral wells. They repeat the exercise in later wells when testing major revisions to the completion design.

Quantifying reservoir properties along the lateral sets realistic expectations for differences in well performance. Hydraulic fracture monitoring with geophones or fiber optics helps operators evaluate conformance to the designed well spacing. Granular measurements of production—at the level of perforation clusters—validate completion effectiveness and identify waste. Together, these data enable clear benchmarking of completion performance and provide feedback to iterate improvement on future wells.

Pausing drilling, to acquire logs in a lateral, runs contrary to industry values of operational efficiency, yet there are many opportunities, where such data aid the construction of more effective wells. Appropriately, recent technology innovations honor the drive for efficiency, reducing time and risk to acquire data in laterals while broadening the range of options for lateral well evaluation.

INNOVATIVE LOGGING SERVICE

One of these options, ThruBit* through-the-bit logging services, provides a full suite of high-quality open-hole logs in the least possible time at the lowest possible risk. Deployed as part of a planned wiper trip after reaching total depth, logging adds only a few hours to well construction time. Slim 21/8-in. wireline tools descend through the drillstring and exit through a portal in the bit. After verifying tool functionality, the wireline is withdrawn, and logs are recorded in memory mode while tripping out. During logging, drillers maintain full well control with the ability to circulate as needed and rotate pipe. All logging tools are retrievable in the eventuality that the drillstring becomes stuck. In normal operations, the tools are retrieved by wireline upon reaching the casing shoe, and data can be verified without tripping pipe all the way to surface.

The through-the-bit logging services provide a full range of open-hole measurements that are combinable in a single descent. Complementing the standard density, neutron, spectral gamma ray, and resistivity measurements, the platform includes an advanced multi-mode dipole sonic tool to fully characterize 3D-anisotropic rock mechanical properties and minimum horizontal stress along the lateral (closely related to frac pressure, and henceforth referred to in this article simply as “stress”). High-definition micro-electrical imaging tools for both water-base and oil-base mud systems precisely determine the stratigraphic position of the well, characterize facies changes, and quantify natural fractures. The combination of Pulsar* multifunction spectroscopy service and other through-the-bit logging services is possible today by wireline real-time conveyance. Moreover, Schlumberger is currently field-testing this combination in through-the-bit logging scenarios. This combination enables quantification of mineralogy, porosity, total organic carbon, and three-phase saturation.

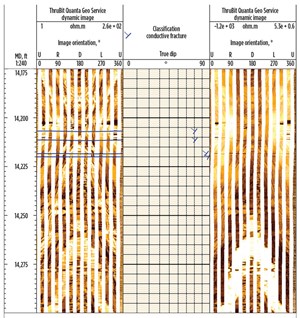

Benchmarking well performance. A Williston basin operator drilled a lateral targeting the upper Three Forks formation, with a data acquisition program appropriately designed to benchmark well performance, Fig. 1. The through-the-bit formation microimager was run to characterize facies and natural fractures, in combination with the through-the-bit acoustic service, which was run to determine rock mechanical properties and stress. The operator executed a geometrically spaced completion design, and after six weeks of flowback and production, deployed a horizontal well production logging system to measure the production of each perforation cluster.

Key insights were gained with applicability to future wells in the play. Significant facies variability of the Three Forks formation, visible in the micro-electrical image, correlated strongly with natural fracture density and variation in stress interpreted from the advanced dipole sonic log. A layer consisting of hard, nodular facies associated with high stress and open natural fractures was identified as especially important. Breakdown was successful despite the high stress, likely due to planes of weakness provided by the natural fractures. The horizontal production log revealed that wherever the well intersected the top of the layer, all perforations were productive—primarily of water, which was interpreted as being drawn from below via the natural fracture network.

Horizontal production logs give a detailed and often sobering view on the effectiveness of hydraulic fracture completions in contrast to what may be a positively biased picture from chemical tracers. Tracers are relatively easy to deploy, providing information on stage contribution—with the limitation that each tracer represents several perforation clusters. A single stimulated cluster may produce tracer when flowing back the well, confirming production for the entire stage or stages. In contrast, a 2011 study of hundreds of production logs revealed more than one-third of perforation clusters across North America do not contribute to production. This equates to billions of dollars expended on fluid and proppant that did not have the intended impact.

Identifying fracing inefficiencies. The problem of poor perforation cluster efficiency is pervasive, persistent to the present day, and represents an enormous opportunity to improve asset NPV. In a perfect world, each cluster is the initiation point for a hydraulic fracture of uniform geometry. For operational efficiency, 4 to 15 perforation clusters are stimulated simultaneously during a stage, yet it may be naively envisioned that each cluster will receive an equal share of fluid and proppant.

There are many reasons why perforation clusters are not stimulated uniformly; however, a fundamental cause is that not all formations are equal. The ideal lateral—where the wellbore stays perfectly placed within a layer of the formation having invariable properties for two miles—rarely exists. Heterogeneity occurs first, because the wellbore drifts up and down in the stratigraphic section, and second, because genuine lateral facies changes occur within layers. Consequently, reservoir quality and mechanical properties will vary along the lateral. Considering that a successful hydraulic fracture will access a large area of the reservoir away from the wellbore, it is easy to dismiss these variations at the well.

But physics dictates that properties in the near-wellbore region exert critical control over the initiation of hydraulic fractures. A challenging—and common—situation occurs when stress varies by several hundred psi between perforation clusters within a stage. In such a case, low-stressed clusters will initiate first and will tend to take most of the slurry before high-stressed clusters break down. Another challenge occurs when natural fractures intersect some perforation clusters but not others. The slurry will go preferentially to clusters where a pre-existing failure provides the path of least resistance. In either case, the result is hydraulic fracture geometry that does not conform to the designed well spacing, which translates to unswept hydrocarbon, frac hits or both.

Several techniques help reduce the incidence of variability or mitigate its impact. Some of the most important include:

- Precise, informed geosteering, with advanced deep or azimuthal real-time measurements

- Completion with near-field diverters to help balance slurry distribution

- Optimization of the completion design, based on measurements.

Completion optimization on a well-by-well basis challenges the standard way of working. Geoscience teams must proactively interpret measurements to feed timely conclusions to the completions teams, who, in turn, use this information to plan and execute each stage. By embracing a more agile approach, where the completion tactics of each well are driven by its unique subsurface characteristics, operators can reap significant benefits.

CASE ANALYSIS 1

For example, a Delaware basin Wolfcamp operator, unsatisfied with prior well results, acquired a set of logs to perform holistic completion optimization. Targeted, nongeometric staging and perforation placement eliminated stress variation within stages. A 3D model was constructed, and various hydraulic fracturing scenarios simulated to optimize fluid type and rate, proppant type and concentration, and overall volume. A key revelation from the logs was an apparent change in clay type from heel to toe, Fig. 2. Laboratory testing of archived cuttings confirmed fluid-sensitive clays near the heel. Previously used reactive chemicals were eliminated; this, alone, netted direct savings of $400,000. Stimulation was executed smoothly at treating pressures consistent with the interpreted stress profile. First-year production came in 70% higher and with better pressure performance than the offset well.

Interestingly, the logs couldn’t be acquired in open hole, using the drillstring, because the well had to be cased, due to the threat of wellbore collapse. Instead, the through-the-bit acoustic and multifunction spectroscopy services were pumped to the bottom of the cased well. Despite the presence of casing and variable cement quality, a complete evaluation of mineralogy, porosity, hydrocarbon saturation, and mechanical properties was provided.

This example of successful evaluation of a cased lateral is not unique. Some operators plan logging in cased laterals to save rig time and further reduce risk. Increasingly in such cases, conveyance by wireline tractor provides a viable, more convenient alternative to pumping tools down, with over 93% success reaching target depth in U.S. onshore operations. Tractoring requires neither pumps nor open-toe perforations, thus it greatly simplifies pressure control and crane requirements. It also enables logging weeks before the frac spread is due on location.

While cased hole logs affirmatively deliver reservoir and mechanical properties in the lateral, they lack in one key area: geologic evaluation. Micro-electrical image logs provide the best characterization of natural fractures and faults but require direct formation contact. A lateral well may intersect thousands of natural fractures, providing the ideal opportunity to collect rich statistics on their density, orientation and aperture for discrete fracture network (DFN) modeling. These data are complemented by fracture length observations from 3D far-field sonic measurements, which use reflected acoustic energy from the dipole sonic tool to identify reflectors, tens of feet away from the borehole.

Understanding the interaction between stimulation and the natural fracture network is important to achieve consistent stimulated reservoir volume honoring the chosen well spacing. A complex function of stress magnitudes, net pressure, and relative orientation, a hydraulic fracture meeting a natural fracture may exhibit several different behaviors, which are explicitly considered in Kinetix* reservoir-centric stimulation-to-production software, where the DFN model provides the environment to simulate hydraulic fracturing in the context of realistic natural fractures.

CASE ANALYSIS 2

A South Texas operator drilled a lateral and acquired a full suite of open-hole through-the-bit logs, including an oil-base micro-electrical imager, Fig. 3. Thousands of bed boundaries and natural fractures were interpreted; their dip was measured precisely and used to construct a realistic, high-resolution, 3D near-wellbore structural and DFN model with a realistic discrete fracture network. The model also was populated with interpreted reservoir and mechanical properties, and 3D hydraulic fracture simulations were run, sensitizing on variations in pumped volume. The model found that non-naturally-fractured stages had simple, planar hydraulic fractures of the planned half-length.

However, in stages of high natural fracture density, natural fractures were dilated, resulting in a complex stimulated fracture network staying close to the wellbore. The entire pump schedule was scaled up for these stages to effectively compensate reduced half-length. A stress-balanced, non-geometric staging and perforation design was employed to reduce chances of run-out hydraulic fractures and frac hits. Stimulation was executed smoothly, and the well subsequently became the operator’s best producer to date.

In the drive for efficient operations, there has been a trend toward more perforation clusters per stage, increasing the risk that variability will result in unequal stimulation. An increasingly popular and valuable technique to help manage the stimulation of multiple clusters is the use of near-field diverter technology—for example, the Broadband Sequence* fracturing service, which uses degradable multimodal spherical particles and fibers to temporarily seal perforation clusters.

A common diverter design assumes approximately half of perforation clusters in the stage will break down and take fluid at lower pressure, due to lower stress or natural fractures, thus preventing breakdown of clusters at higher stress in unbroken rock. The pump schedule is partitioned into two ramps of equal volume, with a diverter pill in-between, sized to plug one-half of the perforations in the stage. After pumping the pill, surface pressure is the main confirmation of successful diversion. The ideal response is a sharp increase as perforations are sealed, then a second breakdown as new perforations are activated, followed by treating pressure somewhat higher than that prior to diversion.

Sometimes the pressure response is not clear; typically, a second, higher concentration diverter pill will be dropped. A third pill may be dropped if required—if there is still no clear pressure signal, what is the next step? Until recently, operators had little choice but to pump the rest and hope for the best. This ambiguity has frustrated some, leading them to avoid diverters and forego the potentially significant benefits.

Such ambiguity can result from the assumption of one-half. For example, one-third of clusters may break down initially—or perhaps two-thirds. Eventually, this results in a wrongly sized pill, and equally partitioning the pump schedule eventually results in both overstimulated and understimulated clusters.

Measurements can reinforce the benefits of near-field diverters with a more rigorously engineered approach. For example, positioning perforations in two distinct groups, based on stress, helps ensure that half initiate at low pressure. The difference between low-stressed and high-stressed clusters can be engineered to target a specific pressure increase upon diversion—1,000 psi being a typical value. When geometric spacing of perforations is the priority, simply observing stress at the perforations provides vision to better partition the volumes, right-size the pill, and interpret the post-diversion pressure signal. It may also identify cases where all perforations are indeed equal, making the stage a difficult candidate for diversion.

VALUE CONFIRMED

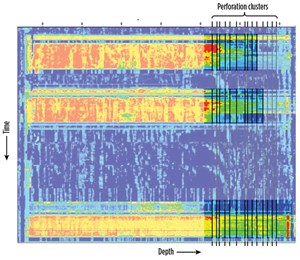

The ultimate validation that diversion is working as designed comes from real-time fiber optic measurements. The recent availability of wireline cables containing optical fibers supporting both distributed vibration sensing (hDVS) and distributed temperature sensing (DTS) makes these measurements accessible in any well, avoiding the significant investment and risk associated with a permanent fiber installation.

Figure 4 illustrates this technology deployed during a Permian basin refrac operation. Real-time vibration sensing data showed that during the first episode of pumping, fluid mainly entered the shallowest few clusters, with further sparse fluid entry to the ninth cluster. After pumping an initial diverter pill, fluid distribution improved but did not pass the tenth cluster. After pumping a second pill, successful diversion was observed, with fluid going all the way to the deepest perforations.

From where it began, the remarkable focus on drilling and completion efficiency has undoubtedly carried the shale industry a long way. But soon, operators will need to look elsewhere for the next improvement in NPV. The selective application of fit-for-purpose measurements at key points in the unconventional development cycle provides necessary vision to reduce common problems, such as frac hits, while improving production and boosting return on completion spending. Well-informed tuning of completion strategies to ensure that they are in harmony with the reservoir and its variation across the play represents an underexplored opportunity to achieve the next level in competitiveness.

*Mark of Schlumberger

- Flexibility and modularity enable tailored solutions for challenging shale plays (December 2025)

- Making shale competitive (December 2025)

- Shale: Sorry Monte Python, I’m not dead yet (December 2025)

- Below-grade well cellar enables simultaneous operations in shale plays (November 2025)

- Cleaner separation, safer future: AutoSep’s automated approach to flowback (September 2025)

- U.S. drilling slows as high operating costs, low oil prices and capital restraint motivate operators (September 2025)

- Subsea technology- Corrosion monitoring: From failure to success (February 2024)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)