DOE/NETL methane emissions research moves forward

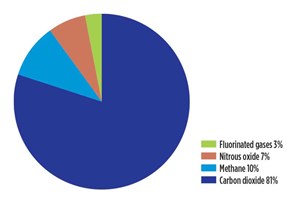

Compared to carbon dioxide (CO₂), methane (CH4) accounts for a significantly smaller percentage of all U.S. greenhouse gas emissions. Methane’s lifetime in the atmosphere is much shorter than CO₂, but CH4 is more efficient at trapping radiation in the atmosphere than CO₂. Pound for pound, the comparative impact of CH4 is greater than CO₂ as a greenhouse gas, Fig. 1.

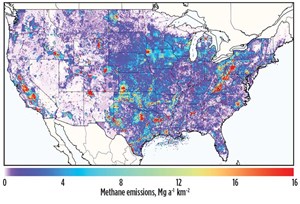

To help quantify the problem, DOE/NETL research and development on methane emissions, to date, has focused on measurements and modeling, to quantify emissions of methane from the extensive U.S. natural gas production system, including emissions from the gas transportation infrastructure, from shale gas operations, from marginal (small producer) wells and from abandoned wells. The R&D also has included funding to develop next-generation methane leak detection technology, combining remote sensing and artificial intelligence capabilities in a system that can operate from an aerial platform. Discussions below cover representative DOE/NETL methane emissions R&D projects that are part of a larger, on-going research initiative, to understand and quantify methane emissions from a number of sources, Fig. 2.

METHANE EMISSIONS FROM NATURAL GAS TRANSPORT SYSTEMS

The U.S. has the most extensive natural gas production, gathering, processing, storage, and pipeline delivery system in the world. However, legacy pipeline infrastructures, many of which are more than 50 years old, are facing operational challenges. DOE’s Natural Gas Infrastructure Program (NGI) is focused on developing next-generation pipeline materials and on enabling new technologies for detecting and mitigating against methane emissions and enhancing the cyber-physical security and resilience of the natural gas pipeline infrastructure. DOE is pursuing R&D on improving the reliability of gathering, compression, transmission and storage system components; creating sensor platforms capable of identifying and quantifying operational risks and methane emissions, and advancing technologies for repairing pipeline damage without disruption of service.

Key program objectives include:

Short-term:

- Quantify the methane emissions from the natural gas industry to improve the U.S. EPA Greenhouse Gas Inventory estimation approaches and inform the NGI Program’s research strategy.

- Quantify the operational efficiency of the natural gas value chain to identify opportunities for improvement that will enhance the efficiency and reliability of the delivery of the natural gas to the public.

Mid-term:

- Develop advanced materials for the interior of natural gas pipelines to resist corrosion and extend the operational range to multiple-products.

- Develop sensors that can be imbedded in future natural gas pipelines to monitor changes in material properties and inform service reliability assessments prior to failure (pipeline explosion).

Long-term:

- Develop the “next generation” natural gas pipeline with longer interior corrosion resistivity, capable of moving multiple-product types, and enabling a self-aware sensing system to alert operators of potential issues prior to unexpected service interruptions.

- Maintain a state-of-the-industry and science knowledge of safety, reliability, and operational efficiency opportunities to maximize the long-term value proposition of natural gas.

- Ensure future natural gas delivery requirements for safety, reliability, and operational efficiency and availability to realize the economic value of natural gas to grow the U.S. economy.

The following lists a few of the key research thrusts within the NGI Program:

- Sensor Devices and Enabling Materials Technologies

- Advanced Materials for Natural Gas Pipelines

- Natural Gas Infrastructure Analysis

- Field-Based Measurements of Methane Emissions from Natural Gas Infrastructure

- Identification, Characterization, and Communication of Operational Efficiency Improvement Opportunities

- Procedures for Systemic Pipeline Monitoring and Leak Detection

QUANTIFYING METHANE EMISSIONS FROM SHALE OPERATIONS

The goals of this project were, among others, to determine the leakage rates of methane from Marcellus shale gas activities at a process level. Methane emissions in the Marcellus shale region were differentiated between “newer” sources, associated with shale gas development, and “older” sources associated with coal or conventional natural gas exploration.

Extensive shale gas exploration and production in the Marcellus region has caused concern about potential environmental impacts on water resources, land and the atmosphere. The overall effects of shale gas development have not been characterized extensively, including the nature and magnitude of the following pollutant emissions:

- Fugitive releases, such as methane and/or VOC leaks at the wellhead, compressor stations, or gas processing facilities

- Emissions associated with support equipment, such as drilling rigs or diesel trucks that service gas wells

- Emissions associated with active venting or well completions

- Discharges or migration of process water used in hydraulic fracturing

- Evaporation of additives used in hydraulic fracturing fluid from holding ponds.

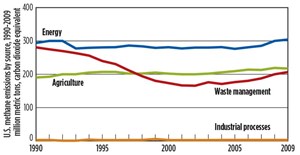

Emission and leak rates of methane and other gases from shale gas activities are, in many cases, estimated rather than directly measured. Quantifying the magnitude of these emissions and understanding their sources at a process level is important to ensure industrial compliance with regulatory agencies, promote public health, and improve public understanding of the risks associated with the shale gas industry. The magnitude of methane emissions from Marcellus shale gas operations should be compared to other possible sources of fugitive methane, such as landfills, agricultural sources, abandoned coal mines, and gas wells, Fig. 3. Quantifying the methane emissions from other regional sources will aid in understanding the net influence of shale gas operations on methane emissions.

Accomplishments. The program, conducted by Carnegie Mellon University, measured concentrations of methane and the tracer by analyzing data for individual plumes at 30 sites. Multiple plumes were detected for each location, and the average emission for each site was determined by computing the WAFLER (weighted average facility level emission rate). One challenge of the tracer flux method is to separate intentional plumes (e.g., the released tracers and methane from the sampling site) from any other potential plumes. This is accomplished by releasing two tracers, and identifying concurrent plumes of both tracers with the correct mass ratio of the tracers. The team also verified the location of the plumes with measured wind speed and direction data. The largest emissions were observed at a compressor station during a blowdown event.

Results from field sampling showed that conventional wells tend to have methane emissions twice that of unconventional wells. The older equipment associated with conventional wells may be one reason for the higher rate, as newer equipment and detection methods are utilized for the new shale gas wells. Based on samples taken, researchers see higher methane emissions at flowback sites than producing wells (either shale or conventional). Emissions are also slightly higher at shale wells than conventional wells; however, the raw emission rate does not account for differences in production between the shale and conventional sites. In general, shale gas wells are larger (multi-well pads) than conventional wells, and also have higher gas production. When normalized against production, shale gas wells (both flowback and producing) emit < ~1% of total production.

Field measurements are beginning to reflect the distribution of emissions across sites, with higher emissions at a few wells and many sites with low emissions. The largest emissions were observed at a compressor station during a blowdown event. Total leakage at each site appears to be correlated with facility size; however, this relationship only describes 55% of the variability between sites. It appears that other factors influence methane leakage rates, as well.

Current status. In southeastern Pennsylvania and West Virginia, total methane production is dominated by newer, high-producing shale wells. But, emissions are almost equally split between new wells and older, less-productive conventional wells.

In northeastern Pennsylvania (NE PA), the normalized emission rate was typically small, with 87% of sites having normalized emissions less than 1% of production, similar to the emission rates observed at shale gas wells in the southeastern portion of the Marcellus shale in Pennsylvania and West Virginia. Oil and gas operations in northeastern Pennsylvania are dominated by newer shale gas wells. Thus, unlike the southwestern portion of the Marcellus shale, there is not a significant contribution from emissions from older conventional wells.

QUANTIFICATION OF METHANE EMISSIONS FROM MARGINAL (SMALL PRODUCER) WELLS

The objective of this research was focused on measurement of methane emissions from marginal well sites at various basins across the United States. The goal was to collect and evaluate representative, defensible and repeatable data from marginal wellsites and draw quantifiable conclusions on the extent of emissions from marginal wells across oil and gas producing regions of the U.S., and to compare these results to published data available on the emissions from non-marginal wells.

Accomplishments. This study will provide a robust, “apples-to-apples” assessment of methane emissions from marginal vs. non-marginal wellsites, based on the quantity and condition of equipment and components within these populations and related operational information. To accomplish this, detailed operating conditions, such as frequency, equipment type, and component counts will be analyzed in conjunction with oil and gas production data for each site, production region, and as a whole.

Recognizing these challenges, GSI proposed to collect and evaluate representative, defensible and repeatable data from each type of well (marginal vs. non-marginal, oil vs. natural gas). These data, together with data from existing sources, will be compiled, evaluated for usability and representativeness, and analyzed to answer two key questions:

- What conclusions can be drawn reliably regarding the relative methane emissions among significant marginal and non-marginal wellsite populations, based on existing available information?

- What are the key gaps in understanding the relative frequency and magnitude of emissions from marginal vs. non-marginal wellsites?

Current status. Once these questions are addressed, GSI will develop a focused, detailed scope of subsequent field investigations, as appropriate, to address critical data gaps. Study conclusions also will focus on identification and implementation of appropriate best management practices, so that the U.S. can continue to rely on traditional oil and gas resources for clean, secure and affordable energy while enhancing environmental protection.

QUANTIFYING METHANE EMISSIONS FROM ABANDONED WELLS

There are an estimated 1.2 million abandoned oil and gas wells nationwide, according to the U.S. Environmental Protection Agency (EPA). Many wells were drilled decades before it was necessary to obtain permits, making it difficult to find them using public records and maps. Additionally, many of these wells were never plugged or sealed when production ceased.

An NETL team recently organized a field campaign in northeastern Oklahoma, a region with a long tradition of oil and gas drilling. For six days in November, a team of NETL scientists, relying largely on information gleaned from various databases, traveled through mostly publicly owned lands, by vehicle and sometimes on foot, to locate abandoned wells and collect methane emission measurements from them.

Accomplishments. NETL’s boots-on-the-ground strategy worked. Researchers collected methane measurements from approximately 140 abandoned oil and gas wells in Oklahoma, easily surpassing their goal to take measurements from 100 abandoned wellsites. The team discovered that just 10% of the wells were plugged with concrete and other materials. Furthermore, about 10% of the unplugged wells registered measurable leakage rates of methane.

Patricia Saint-Vincent, an Oak Ridge Institute for Science and Education Postdoctoral Associate for NETL, said being on the ground in Oklahoma yielded unexpected, positive surprises. “We met and developed relationships with residents, who could remember locations of wells that were never documented on public records or maps,” Saint-Vincent said. “They helped us find wells that were covered by thick vegetation or debris, and would have been impossible for us to find on our own.”

“Capturing methane before it leaks into the atmosphere helps reduce the effects of climate change,” Dr. Natalie Pekney, NETL Technical Portfolio Lead, said. “The levels of methane leaking from a single well may be relatively small. However, given the large number of abandoned wells, the cumulative amount of methane they release may be substantial.” Field work at abandoned wellsites also provides valuable data about how various environmental factors, such as barometric pressure and soil conditions, influence the dispersion of leaking methane into the atmosphere.

Current status. Data from NETL’s work in Oklahoma, along with its other efforts to measure methane emissions from abandoned wells and pipelines in other parts of the country, will be shared with the EPA. The data may then be listed in the EPA’s Greenhouse Gas Inventory, which policymakers use to develop strategies for emissions reductions and to track the progress of those policies.

Developing Next-Generation Leak Detection Technology

NETL is expanding its work with the Southwest Research Institute (SwRI) to develop the next generation of methane leak detection technology, combining remote sensing and artificial intelligence capabilities in a system that can operate from an aerial platform. This approach can more effectively help alleviate methane emissions from multiple operations in the natural gas industry.

The objective of the new research is to develop an airborne, autonomous, real-time leak detection technology that applies machine learning techniques to passive optical sensing modalities to mitigate emissions through early detection.

Accomplishments. NETL has supported SwRI work on the Smart Methane Emission Detection System (SLED/M) since 2016, and key progress has been made on a system that monitors various regions of a gas pipeline facility and interacts with natural gas mitigation technologies. However, so far, SLED/M has been land-based.

According to NETL’s Joseph Renk, an additional task was recently added to a cooperative agreement with SwRI (DOE Project DE-FE-0029020 “Smart Methane Emission Detection System Development”) to develop technologies that allow the leak detection system to operate from an aerial platform or drone. NETL Director Brian Anderson said there is accelerating interest from the natural gas industry in this new technology, because of its ability to detect methane that might otherwise go undetected by the current state-of-the-art optical gas imaging equipment now used.

Fugitive emissions from compressors are one of the largest sources of methane emissions in the midstream sector of the natural gas industry. SwRI reports that 50% of fugitive emissions are from major compressor equipment, and 10% of emitting sites contributed to 50% of overall methane emissions. Existing methane detection technologies have deficiencies, including high false alarm rates. They also require operators to process the data in real time or in post-process. The SLED/M approach, combining remote sensing and artificial intelligence technologies, has demonstrated low false alarm rates and a reduction in both response time to leak detection and operational costs. In addition, the approach does not require a human in the loop, which minimizes error. SLED/M is a non-intrusive, passive technology, meaning there is no need to retrofit existing equipment and facilities, eliminating safety and operational restrictions.

Current status. Under the new work, SwRI will perform testing, collect data, and develop a machine learning-based methane detection algorithm to detect leaks from a drone, using the existing SLED/M components. SLED/M has already gained industry interest from its proven ability to detect methane, and the integration of methane quantification will provide companies an all-in-one solution that is accurate, reliable, autonomous, affordable and easily integrated with existing operator-owned equipment. As a recent Stanford study found ("https://www.elementascience.org/articles/10.1525/elementa.373/" \t), only one in nine tested methane detection technologies reliably measured the gas. There is a clear need for improved technologies.

- Advancing offshore decarbonization through electrification of FPSOs (March 2024)

- Digital transformation: Accelerating productivity, sustainability in oil and gas (November 2023)

- Technological advances increase efficiencies and flexibility (November 2023)

- Volatile organic carbon emissions in oil and gas industry: Impact and mitigation (November 2023)

- Technological innovation delivers transformative product suite to upstream sector (November 2023)

- Executive viewpoint (August 2023)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)