Electrochemical water desalination system reduces EOR costs

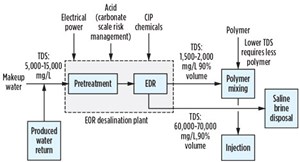

An electrodialysis reversal (EDR) system, that requires minimal pretreatment with innovative hydrocarbon anti-fouling ion exchange membranes, was packaged in rugged skids with advanced process controls. The EDR plant can: 1) desalt EOR produced water from up to 20,000 mg/L, total dissolved solids (TDS), down to 500-5,000 mg/L for reinjection; and 2) reduce polymer requirements to decrease chemical costs in polymer flood operations. EDR desalts via an electric field—dissolved ions in the produced water are moved across ion exchange membranes, desalting one stream while concentrating a smaller volume discharge. The TDS in the produced water can be desalted to any concentration that provides optimal performance specific to the reservoir.

Depending on the presence of scaling ions, the concentrated stream can achieve TDS concentrations of 80,000 to 150,000 mg/L or, in the case of offshore oil and gas, the concentrated stream can be eliminated through a novel process. EOR operators may add polymers and other chemicals to increase the viscosity of injected water and enable increased oil recovery.

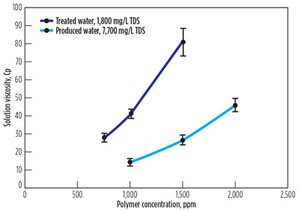

Testing proved that EOR polymers present in the produced water, that returns to surface, do not foul or pass through the EDR membranes, but instead remain in the desalted water for reuse. In fact, some polymers are “reactivated” in the desalted output, with viscosity increasing by almost double during desalination, and thereby enabling some “recycling” of original polymer. More importantly, results proved that lower TDS of the injected water can result in up to 65% polymer cost-savings, which is a major contributor to operating costs (i.e. $2 million to $10 million/year expense for 1,000 to 4,000 m3/day injection). Polymer consumption increases with TDS, to reach a target viscosity goal. Therefore, desalting the injected water can result in net savings, if desalination costs are lower than the incremental polymer consumption savings, delivering 30%-to-40% ROI.

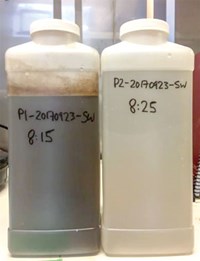

To test the theory, an off-site pilot was first completed in advance and to prepare for on-site work. Produced waters up to 20,000 mg/L, TDS, with oil-in-water present up to 600 ppm, were tested. Pre-filtration consisted of proprietary media filtration to remove suspended solids to less than 20-μm particle size. No pretreatment for the oil was required, which was confirmed during subsequent pilot testing. This is due to the resiliency of the anti-fouling ion exchange membranes, EDR stack design to prevent plugging, and intelligent cleaning systems that detect and react to remove fouling or partial plugging prior to irreversible events.

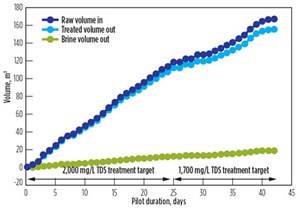

After the off-site work passed technical and economic hurdles, an on-site pilot was then constructed and delivered to a live EOR oil field. It operated for 60 days with 100% reliability, unattended overnight, and achieved all technical goals, including rugged operations in temperatures as low as -14°C and winds up to 100 km/hr. The EDR system met the desalination objective of 2,000 mg/L TDS with 90% desalted water recovery achieved and was subsequently tested to desalt to lower TDS targets. Polymer addition testing also was completed on a range of desalted produced water TDS concentrations, demonstrating up to 65% polymer reductions and the resulting operational cost-savings.

These results and economic analysis show an optimum TDS desalting point, which relates to the EDR plant size and cost, and the amount of polymer required to reach the desired viscosity. In the pilot case, this optimal point was about 1,700 mg/L TDS output.

PRODUCED WATER DESALINATION

Desalinating produced water offers EOR sites an option that optimizes the salinity of injection water for improving extraction of original oil in place (OOIP), while also enabling water reuse for future waterfloods. However, EOR waters are unique and not a fit for all desalination technology.

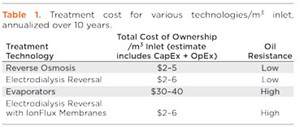

The most popular desalination technology on the market is reverse osmosis (RO), which pushes water through semipermeable membranes at pressures up to 1,000 psi and creates low-salinity (<500 mg/L) water. The challenge facing conventional RO technology in EOR is the oily nature of produced water that contains hydrocarbons including solvents. RO membranes are susceptible to swelling and damage in oils and solvents, as well as fouling in the presence of other organics. It is possible to remove hydrocarbons by pre-treatment, yet this can be cost-prohibitive. Nevertheless, the authors recognize that reverse osmosis is an excellent technology, and the best economic option for seawater and brackish desalination if brine disposal is available.

Evaporators are another technology available for treating produced water, and they reach even higher concentrations of brine and equivalently greater quantities of treated water for reuse. However, they generally cost nearly 5- to 10-fold greater per unit of water treated, when compared with a RO unit. They are also larger, heavier, and more energy-intensive, making them a poor fit for offshore EOR.

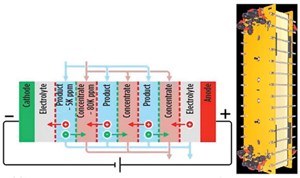

The solution involves leveraging a 40-year-old, low pressure electrodialysis reversal (EDR) membrane technology used for desalination. EDR underwent recent innovations in membrane composition, stack design, and process controls that enable its use on produced waters without extensive pre-treatment. Electrodialysis reversal (EDR) avoids the use of pressure difference across membranes, which is one contributor to fouling in a RO system, in favor of driving desalination by applying electricity across ion exchange membranes to separate ions by charge, Fig. 1.

Since conventional EDR membranes will swell and fail in the presence of oily wastewater, the authors employed hydrocarbon-resistant ion exchange membranes, which were developed and tested to specifically withstand hydrocarbons and solvents through novel cross-linked polymer composition, including both ion conductivity and ductility. They also exhibit the added benefit of selectively removing multivalent ions and were, therefore, selected for this work after testing other membrane options.

When desalinating saltwater, operators will need to consider what to do with their concentrated, higher-salinity brine left over. Since it has significantly reduced volume compared to the raw produced water stream, it may be more economic to send for disposal, Table 1. Alternatively, it is possible to pair any of the above treatment options with zero liquid discharge technology, such as crystallizers, to produce freshwater and residual solids.

EQUIPMENT SETUP

After off-site trials on three produced water sources, ranging in salinity from 5,000 to 20,000 mg/L, were successfully concluded and economics confirmed, a fully integrated and automated pilot plant was designed, constructed and delivered to site. It consisted of full-scale components to be used in future plants, and was operated for 60 days, 24 hr/day, including unattended night operation. The plant operated reliably and continuously through major process upsets, including oil-in-water spiking from 50 to 1,000 ppm, and two severe weather events, including winds in excess of 100 km/hr and freezing conditions. Saltworks Technologies of Vancouver, Canada, completed the design, construction and operation of the pilot plant; however, the plant test plan and installation were completed in partnership with the oil and gas site owner.

The plant was outfitted into two 40-ft shipping containers for mobility to future trial sites. One shipping container included a pre-treatment system, small wet-lab, operator desk, and spare parts storage. The second shipping container consisted of the electrodialysis desalination system, tanks, electrical panels, and controls. Allen-Bradley PLCs provided system automation, with all programming completed using the ControlLogix software platform. A remote operating and alarm notification system was installed by means of a 3G cellular link, Fig. 2.

Proprietary media filtration was used for pre-treatment, which could be back-washed and aggressively chemically-cleaned without degradation. The pre-treatment goal was to reduce particle distribution to less than 20 μm (goal 15 μm), which prevents clogging in inlet manifolds built within the electrodialysis stack. Oil and hydrocarbon products do not need to be removed, however, coagulation of larger hydrocarbons and oil can occur within both the pre-treatment and electrodialysis stack. Coagulated oil that may accumulate over long periods of time was readily removed by either a backwards flush, or a more aggressive pH 11 wash, if necessary. The high pH wash fluid was recycled and re-used multiple times. Backwash fluid was filtered via bag filters and sent to the inlet of the plant and retreated.

Desalination was completed by a full scale electrodialysis stack under anaerobic conditions. A Saltworks Flex EDR Organix E200 stack, with Ionflux ion exchange membranes, was employed. Ionflux ion exchange membranes were selected, due to their resilience to oil, hydrocarbons and oxidants (i.e. bleach cleans). Electrodes were coated with titanium and protected from calcium fouling via an “electrode blocker” that removes the need for chemical softening and enables operation on high-hardness saline waters. Flowrates were limited to 5m3/day, due to pre-treatment capacity and, as a result, only 15% (or 40 layers) of the potential 300 total membrane layers were installed in the full scale electrodialysis stack.

Current density, which is a measure of “salt flux” out of the treated water through the membranes, was varied from 40 to 200 A/m2. The electrodialysis stack was kept clean and descaled by use of self-cleaning automation that used active monitoring and machine learning to refine and inform cleaning cycle options, including ion current reversal, hydraulic flushing, and chemical cleaning.

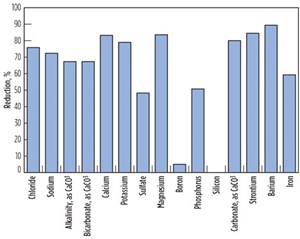

The produced water at the field test site averaged 7,000 mg/L TDS, and it was desalted to the target concentration of 2,000 mg/L TDS (Fig. 3.), and then desalted lower, approaching 1,000 mg/L TDS with the mid-pilot optimal target being 1,700 mg/L TDS, Fig. 4. Pre-filtration improved turbidity and reduced solids distribution to the target < 20 μm particle size. Approximately 90% desalted water recovery was achieved while treating the produced water, in the presence of up to 1,000 ppm oil-in-water, averaging 500 ppm. Notably, calcium, magnesium, barium and strontium, all components of hardness that have the potential to cause scale and increase oil-wetness within a reservoir, were decreased substantially in the final treated water stream. Fig. 5. The final TDS was 2,100 mg/L, which compared favorably compared to inlet produced water with an initial TDS of 7,500 mg/L.

PROJECT ECONOMICS

EOR desalination can be economic if either: 1) where lower salinity, or hardness removal, increases oil recovery in conventional water flood options; or 2) where polymer flood is employed to increase injected water viscosity and oil sweep. This work focuses on the latter.

Polymer savings will vary widely from site to site, depending on desired final viscosity and chemical make-up. For early project feasibility estimates, our data suggest that at least 50% polymer savings can be achieved for chemical flood operations, and possibly much more at higher TDS concentrations. This is because much higher injected water viscosities can be achieved at lower polymer concentrations, if a lower TDS water source is employed, or produced water is desalted to a lower TDS, Fig. 6.

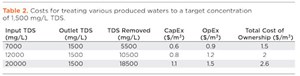

Although site economics will vary, as a guide, a typical 1,000-to-4,000 m3/day polymer injection site may consume $2 million to $10 million/year in polymer operating cost. For the sake of this work and aligned with the pilot on 7,000 mg/L TDS inlet, it is assumed that polymer costs amount to $5.5/m3 injected without desalination. The 65% polymer cost-savings could amount to $2.5/m3 in polymer savings. On the cost side of the equation, Table 2 highlights various scenarios, where different input concentrations of TDS are treated to a target of 1,500 mg/L TDS, and the change in capital and operating expenses/m3 of water treated is annualized over 10 years. The 7,000 mg/L scenario results in an estimated total cost of ownership of roughly $1.5/m3, vs the polymer cost-savings presented above of $2.5/m3.

The net result is 40% savings in total costs, based on polymer savings alone, not factoring in possible added benefits, such as increased oil production from injected water chemistry, reduced freshwater withdrawal for make-up, reduced disposal, and/or reduced injection into other parts of the reservoir that could otherwise be used from production. It is emphasized that every case is different, and at higher TDS inlets, the economics of desalination vs. polymer savings need to be checked.

Although polymer savings increase at a higher TDS inlet, capital and operating expenses also increase with greater changes in TDS concentrations. This is because EDR operates by mass flux of ions through membranes, and, therefore, a greater change in TDS increases mass flux, which increases both membrane area (CapEx) and electrical energy (OpEx). Every site will have its optimal economic “sweet spot” for desalination rate vs polymer consumption, which can be determined by off-site pilot tests (bench tests) with relative ease.

CONCLUSION

With EOR set to increase its share of global oil production in the coming years, offering economic options for operators to improve their recovery methods will help improve OOIP yields from existing wells at lower costs. In turn, this maximizes value from existing assets and lowers the net cost of production/bbl of oil. Desalinating produced water from polymer flooding EOR offers strong potential to lower the cost of production, while also reducing water use and disposal.

Until now, conventional membrane technologies faced the challenge of overcoming the harsh operating conditions and hydrocarbons found in EOR. Recent innovations in EDR have proven early success to withstand EOR in-field operating conditions and desalinate produced water with a possible 40% return on investment.

Next steps include a permanent installation operating at a higher capacity.

- Water management: New disposal well requirements (January)

- Water management: The New Mexico soap opera (November 2025)

- Improving produced water management with electromagnetic flowmeters (November 2025)

- Chemical-free scalable technology for produced water treatment (August 2025)

- Produced water: From waste to resource (August 2025)

- First Oil: Texas Supreme Court clarifies ownership of produced water in O&G leases (July 2025)

- Subsea technology- Corrosion monitoring: From failure to success (February 2024)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)