What’s going on down there?

Investors are demanding a higher return on every dollar spent in the oil field, and oil and gas companies are scrambling to create strategies to improve production while mitigating risks in an ever-volatile market. With the WTI oil price hovering between $55/bbl and $60/bbl, and operators suggesting that an average WTI price of $50/bbl is needed to profitably drill new wells in unconventional reservoirs, the need for a step change in understanding development strategies has never been clearer.1

For nearly 20 years, developing unconventional reservoirs has reversed America’s declining production, spurred by technological advances. Central to these have been horizontal drilling and multi-stage hydraulic fracture stimulations. Despite all the advances, fracs can still deliver costly, unwanted effects—under-stimulated reservoirs, wasted materials, excess water production; bottom-line poor returns. As McManus & Young point out, these effects can lead up to a million dollars in over-expenditures per well.2 These are additional wasted costs that operators simply cannot afford to take on. What causes this waste? That is a question operators unfortunately don’t know the answer to, as well as “What’s going on down there?”, until the damage is done.

This story doesn’t have to end badly. To aid well design optimization, frac monitoring has become a diagnostic tool to examine the operational efficiencies. Diagnostic tools can uncover what’s happening “down there” in the subsurface and identify the root of the problem. A new tool is electromagnetics; the mining industry darling has found its way into onshore unconventionals, including plays like the Permian basin. This tool is brought to the industry by Deep Imaging with new insights.

THE CHALLENGES

Fracing is an old procedure, dating to the late 1940s. Yet, it still has many unknowns. An all-but-too-familiar phenomenon happens when drilling and fracing new wells (“child” wells), near older wells (“parent” wells). Coined as “frac hits,” this detrimental occurrence is the result of undesired inter-well communications between the parent well and the child well, due to hydraulic fracturing operations performed on the child well. The occurrence is exceptionally frequent, given operators’ willingness to take on the risk of pushing the envelope of frac design optimization. Frac hits have been the bane of many operators’ existence during both lease preservation and full-field development modes in unconventional operations.

In the same vein, the question still lingers, “To minimize hits or other detrimental long-term effects, how should I complete a pad?” To answer, a myriad of designs are being tried to mitigate hits on neighboring wells and pads. These designs are predicated on models that predict barriers and buffers between the active stimulation and the neighboring wells. These models need verification and tuning.

Models introduce many variables that lead to million-dollar questions. There is the risk of under-stimulating and missing production, or over-stimulating, which wastes capital and resources. What might work in one basin may not work in another. For example, over the past decade, there has been a drastic shift in completion designs. The trend has been “bigger is better.” Unfortunately, not all basins saw the same favorable shift in production. Uneconomic wells can demolish a development program.

Unconventional reservoirs are complex: naturally fractured, multi-layered, and geologically heterogeneous, for example. The complexity spans from the micro to the macro scales. To evolve completion designs in developing a field, the models must have enough information to understand, and include, the complexity. Is there a best stage length and frac design for a given well spacing? What’s the best well spacing? Is one area of a field different than another, calling for a different frac strategy? The ability to image what frac fluids are doing is needed by the designers and on-site frac engineers to answer some of these questions, and electromagnetic monitoring provides this ability.

THE TECHNOLOGY

The electromagnetic method is a non-intrusive, controlled-source method that uses a high-powered source (transmitter) to transmit a signal to multiple adjacent receivers. Using the “casing as a source” method, the transmitter cable is placed on the surface above the lateral of a horizontal well, where the transmitted signal couples with the well casing to deliver a response to receivers on the surface that originates from well depths. One operational strength of this method is that no equipment or person needs to ever interact with the well or pad. Time-based variations in the signal response are sensitive to characteristics and changes caused by fluid injection. Data processing extracts this sensitivity to image the behavior of the frac fluid.

THE FIELD OPERATIONS

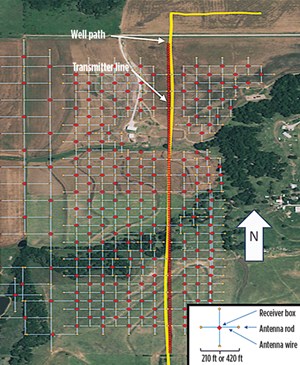

Deep Imaging field operations begin with the creation of a survey design based on client needs and expectations discussed before the operation. Prior to survey set-up, the field is scouted to assess any hazards that need to be addressed, if deemed detrimental to operations. Once survey operations commence, receiver and transmitter points are surveyed for positioning. To run operations, a staging area is required. The staging area consists of four major components: a mobile office for data monitoring and collection; two trailers for equipment storage; and a generator.

Data acquisition equipment consists of a transmitter; transmitter cable grounded at both ends; a generator to power the transmitter; and receivers. The receiver configuration consists of a receiver box connected to two sets of sensor wire that are also grounded using copper rods, and an antenna to ensure communications between the box and the mobile office.

Everything is set up, off-pad, to avoid affecting frac operations, where communication is maintained with the operator to know when frac stages start and end. All survey equipment is laid out on the surface of the recording field. Utility task vehicles and high-clearance vehicles allow access to the site using pre-existing roads. The application of surface operations, and the use of smaller vehicles, creates little-to-no environmental impact. How all this comes together, is discussed below.

THE FIELD STUDIES

With use of the electromagnetic monitoring, problems in well isolation and frac design have been identified in operations across Texas and Oklahoma, which have led to fluid waste and over-stimulated reservoirs. These problems resulted in loss of capital and returns, affecting the overall profitability of the operations.

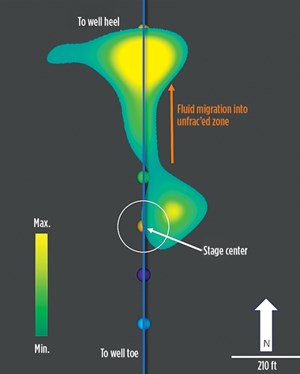

For each stage, a signal is transmitted prior to the start of fluid injection and continuously throughout the frac stage. During processing, a signal generated by background activity is subtracted to isolate only what is caused by fluid injection, where it can then be imaged, as shown in the following figures.

Over-stimulation of a well. Deep Imaging monitored a single, horizontal well frac operation, where the stage lengths had been shortened significantly. Figure 1 shows a map view of the field set-up, including transmitter and receivers.

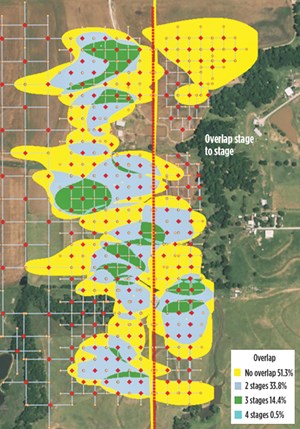

The data showed extensive stage overlap for about 50% of the stages (Fig. 2), indicating that many of the stages resulted in the stimulation of already-stimulated zones in the reservoirs. This was most likely due to the short stage lengths utilized. This re-stimulation led to expenses that could have been reduced, using increased stage spacing and reduced stage size.

Additionally, the operator reported that fluid from this frac interacted with a neighboring parent well. Deep Imaging observed this communication and was able to identify not only which stages, but also the path that the fluid took to get there.

Poor well isolation. Deep Imaging also has identified stage isolation problems using electromagnetics. Figure 3 shows signal propagation (orange arrow) invading north of the expected stage (stage center). The fluid is invading a not-yet-stimulated zone to the north of the wellbore. The frac extent could have increased over time, but due to loss of fluid, only a portion of the reservoir was stimulated. Stages have been seen to communicate along the annulus, three stages toward the heel, before entering. This is likely due to poor cement coupling leaving the reservoir untreated and with excess operational costs.

The electromagnetic technology can meet client goals of determining frac quality, identifying stimulated and non-stimulated zones, and identifying completion hazards. For more Deep Imaging studies, see Hickey et al.3,4 and McManus & Young.2

THE FUTURE

Deep Imaging’s true goal in deploying this electromagnetic method is to provide real-time imaging. By providing information on problems not readily identifiable to the frac engineer in real time, operators can use the information received to optimize their well designs on the fly, as opposed to waiting on the next redesign for future well pads. Real-time decision-making can allow operators to improve efficiency and production.

The unknown doesn’t have to be so scary, and occurrences in the subsurface impacting production don’t have to wait “until next time” to be mitigated. The electromagnetic tool is relieving the fear of the unknown, such that operators can now answer the vital question: “what’s going on down there?” WO

REFERENCES

- Rassenfoss, S., “Make or breakeven: Is unconventional oil production getting more efficient?” Journal of Petroleum Technology, May 24, 2019.

- McManus, S., and S. Young, “Novel understanding of frac fluid placement through agile electromagnetic monitoring,” in R. Gales & D. Leonard (Chairs), Applied Data Science and Novel Measurements for Unconventional Development. conference conducted at the 2019 International Conference and Exposition of SPE, Phoenix, Arz.

- Hickey, M., S. Trevino III, and M. E. Everett, “Detection and characterization of the injection of hydraulic fracturing fluid using ground-based controlled-source electromagnetics,” SEG Technical Program, Expanded Abstracts, pp. 1039-1043, Society of Exploration Geophysicists, 2015.

- Hickey, M., O. Vasquez, S. Trevino, J. Oberle, and D. Jones, “Using land-controlled source electromagnetics to identify the effects of geologic controls during a zipper frac operation–A case study from the Anadarko basin,” SPE, 2019, doi:10.2118/194313-MS.

- Shale technology: Bayesian variable pressure decline-curve analysis for shale gas wells (March 2024)

- Using data to create new completion efficiencies (February 2024)

- Prices and governmental policies combine to stymie Canadian upstream growth (February 2024)

- U.S. producing gas wells increase despite low prices (February 2024)

- U.S. drilling: More of the same expected (February 2024)

- U.S. oil and natural gas production hits record highs (February 2024)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)