Well integrity in production operations: Five trends shaping the future

Five trends in well integrity (WI) for production operations have emerged, with significant implications for the industry’s future direction. The increased focus on managing WI is being driven by heightened awareness of the latent risks and consequences of well integrity failures.

INTRODUCTION

Well integrity must encompass the entire life of a well—from its initial construction (planning, drilling, completion and testing), through its producing life (or in injection service), until the well is finally decommissioned and abandoned. This article focuses on WI in production operations and five major trends in managing WI that, the authors believe, will be integral to shaping the future direction of the oil and gas industry. A holistic view is taken that incorporates organizational, workflow (or business process), tools (IT systems), and data and information perspectives. The intent is to provide a high-level survey of industry trends and not delve into specific engineering methodologies or technology. Figure 1 highlights the production operations phase, which is the scope of this article. The selection of this focus area, however, is not intended to diminish the importance of WI outside the scope of production operations.

The increased focus on managing WI is being driven by a heightened awareness—across the industry, regulatory agencies and the general public—of the latent risks and consequences of WI failures. The recent Southern California Aliso Canyon underground storage facility’s gas injection well failure serves as a potent example of the potentially disastrous consequences. The casing failure resulted in a large natural gas release to the atmosphere for over three months, and the temporary relocation of over 10,000 local residents. It represents the largest gas leak in U.S. history, in terms of its environmental greenhouse gas emissions impact.

TREND 1

Defining well integrity ownership. Clear ownership of WI in an organization is increasingly recognized as a requirement for success. When ownership is diffused or ambiguous, everyone—and therefore no one—is truly focused on, or ultimately responsible for, rigorously monitoring and driving improvement in WI across the lifecycle of a well. Establishing clarity of WI ownership is complex, however, due to the diversity of activities and disciplines that interact during the lifecycle of the well.

A good analogy for this is an automobile, owned and operated by someone for personal use. In this scenario, who is accountable for the vehicle’s mechanical integrity? Certainly, the owner/driver plays a role, based on how well, and often, the car is inspected for proper fluid levels, tire pressure, or any apparent mechanical issues. The owner/driver is also responsible for hiring a skilled mechanic to perform any maintenance, and complete repairs or replace any worn-out equipment. The driver’s behavior also makes a difference; a large pothole in the street, for example, could damage or weaken the front-end components and put the integrity of the vehicle at risk.

But what about the role of the car’s manufacturer? The design and manufacturing quality certainly contributes to the vehicle’s safety and performance over its lifecycle. These are beyond the control of the owner/driver, once the decision to purchase the vehicle is made. So, the manufacturer is initially the “integrity” owner, which then transitions to the initial owner, when the vehicle is purchased. Similarly, if the original owner decides to sell or dispose of the vehicle, the subsequent owner(s) may suffer integrity issues that are not of their own making, if the design was flawed or the initial owner failed to maintain or operate the vehicle in a responsible manner.

Thus, in similar fashion to an automobile, multiple parties play a role in ensuring WI in production operations. The primary ownership of WI during the production operations phase moves between the wells and production operations disciplines, depending on the well status and activity at a particular time. Monitoring the well on a day-to-day basis for evidence of WI issues is typically the remit of production operations, with the frontline operators flagging issues that can be observed directly (abnormal pressures, temperatures or leaks), and the production/petroleum engineer (PE) providing surveillance, based on longer-term trends or performance. The PE also typically serves as the liaison with the wells discipline, to communicate and jointly diagnose the issue, taking into account both a downhole and surface facilities perspective. One challenging aspect of this is the dual role for the PE in balancing any conflict of interest between long-term and short-term performance and maintenance of the well.

TREND 2

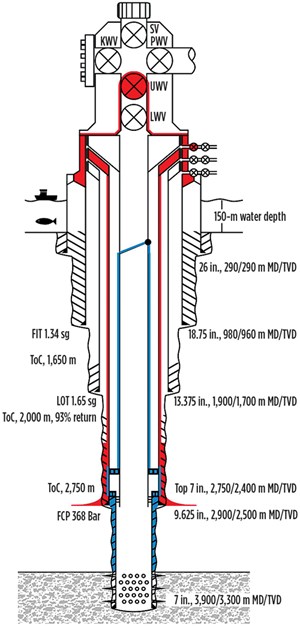

Adopting a well barrier mind-set. The design, construction and operation of wells specify and incorporate equipment and materials (such as casing, cement, tree and wellhead valves) to isolate the produced or injected fluids from the environment, and provide a pressure containment envelope. The adoption of a well barrier mind-set, as a guiding principle that permeates the design, construction and operation of wells, ensures that WI is being managed systematically. This well barrier concept—articulated in the NORSOK D-010 Well Integrity in Drilling and Well Operations standard, when it was first published in 1986—is a simple, yet powerful, way to visualize and communicate how the individual elements combine together as a system to provide an integral pressure-containing envelope for the well.

So the essence of a well-barrier mind-set is to manage WI from a systems perspective, rather than addressing issues on a component-by-component basis. To visualize this and further reinforce the concept, Fig. 2 illustrates a well barrier diagram that portrays the system by highlighting the primary and secondary pressure-containing envelopes.

This well barrier diagram style complements the more traditional wellbore schematic. The well barrier diagram is analogous to the piping and instrumentation diagram (P&ID) that provides a simplified view of the pressure-containing envelope (e.g. piping and vessels) for production facilities. Creating and maintaining well barrier diagrams, for either individual wells or groups of wells by type (necessary for large populations of well stock), is a work in progress for many operators. Adoption has not been universal, however, with some operators questioning the value relative to the effort required to develop and maintain detailed well barrier diagrams. As with all new methodologies, the relative merit will become clearer over time.

In addition to defining the well barrier envelope, determining the well barrier design, and operating pressure limits and status, are equally important. The maximum, allowable, annulus surface pressure (MAASP) is typically defined, along with the lower operating limit (MOASP), to provide some margin for error, as well as set the pressure levels at which a review of the well condition must be undertaken to determine if any action, such as shutting in the well, is required. The well barrier status is typically defined as either intact, impaired or failed. The well status is defined for both the primary and secondary barriers, with the impairment or failure of one barrier elevating the risk for a potential loss of containment, should the remaining intact barrier fail.

When a well integrity issue, or something unexpected is detected, this well integrity “anomaly” is then reviewed and diagnosed, and any remedial actions are identified and executed. This case-management approach for managing anomalies provides a robust way to continuously monitor for, and effectively respond to, threats to WI as they emerge. Over time, analysis of barrier impairment and failure data can be used to proactively identify root causes of the anomalies and, in turn, develop standardized steps to minimize anomalies and thus enhance reliability. Reporting also can be developed, which clearly communicates the well barrier status, anomaly management effectiveness and other performance management indicators to key stakeholders. Based on this, actions can then be undertaken to improve the overall performance. This workflow, underpinned by adopting a well barrier mind-set, is illustrated in Fig. 3.

TREND 3

Proactively managing WI risk. Many operators are pursuing a common goal with respect to WI—to develop and sustain a risk management process that effectively assesses and reports the relative WI risk across the companies’ entire well stock. One senior executive of an operating company called it their “Magic Button” that presents, at the press of a button, a high-level view of all WI risk. While the concept is simple to understand, developing and then sustaining this is proving to be challenging for many operators.

One key issue associated with delivering this aspiration is that the required, basic data and information must be collected, stored and maintained in a software application to allow for accurate and efficient calculations, analysis and reporting. The required data include an inventory of all well equipment; downhole materials and conditions; well construction and intervention operations reports; tests performed and results; and basic well measurements, such as pressure, temperature, produced or injected volumes and fluid composition.

These data may be available, but historically they have been collected and maintained in a variety of formats, software applications and documents. Locating the data, then reviewing and upgrading the quality of the data, and finally migrating it into a consolidated system, is a daunting, challenging task, even for one well. The quantity and quality of the data must also be sustained moving forward, with all future measurements, tests, reports, and equipment and well condition information, captured on an ongoing basis and managed in a coherent fashion to produce usable information.

Another key issue is that a risk-classification system must be developed that equates specific well conditions and hazards with the level of risk associated with that particular well condition. This classification scheme typically factors in the probability and consequences of a potential loss of containment, as well as the well-barrier status (intact, impaired or failed). The results are typically presented on a matrix, such as a 4-by-4 grid or larger, with the higher-risk wells presented in the upper right-hand corner of the matrix.

The ISO/DIS 16530 Well Integrity standard also proposes a well failure model that is intended to streamline the risk assessment process by matching typical well failure modes (e.g. tree master valve failure, annulus-to-annulus leak) with an associated action plan and response time. This approach also may allow the operator to more effectively assign appropriate response times and allocate the required resources to address the risk. Given these issues, as well as other challenges, this will remain a work in progress for many operators in the near term.

TREND 4

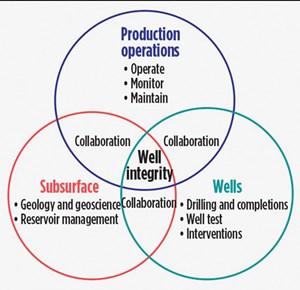

Building organizational capability. There has been a long-term trend toward increasing organizational capability in WI, driven by the emergence of WI as a technical speciality in its own right, as well as the recognized need for engagement and participation of multiple disciplines. Certainly, the ongoing industry downturn has dampened this trend from a headcount perspective. Still, the focus on building increased skills and knowledge in WI across the broader workforce remains. The subsurface, wells, and production operations disciplines each play a significant role in managing WI, Fig. 4. The level of organizational capability required for each discipline, whether awareness, practitioner, or mastery level knowledge and skills, varies, based on the specific role.

Many operators already recognize the need to enhance the WI capability of Production Operations personnel and are taking action. To build more specialized skills in managing WI, some operators have created a dedicated WI engineer position, either as a central staff engineering role, or a member of the regional business asset team. The WI engineer’s role brings more WI focus and deep expertise into play, but it also results in additional staffing at the central and regional levels. The majority of operators have not invested in this dedicated WI role at the regional business level, but they instead count on the PE to manage any WI issues. This continues until the need for service or intervention work has been confirmed, and the well is handed over to the wells discipline to plan and execute the well work.

TREND 5

Developing fit-for-purpose data management systems. Historically, well integrity data management has been hampered by data isolated at asset levels, regional differences in operating conditions, and unclear accountability for data management. Integrity activities are documented in diverse places that include: the well file, maintenance systems or offline spreadsheets. The adoption of large enterprise systems, such as SAP or Maximo, has not been easy for field operations, and they are often supplemented by in-house reporting solutions.

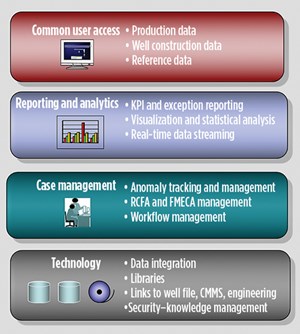

The trend toward fit-for-purpose systems has evolved from reporting tools to technology suites, providing richer case management and analytical capabilities. The overall goal is ease of use and reporting, with analytical functionality focused on well integrity performance. A typical fit-for-purpose system includes the system components illustrated in Fig. 5 and described below.

- Common user access—Gateway to the wide variety of well construction, production, and reference data stores and libraries. Secure access from anywhere, and on any device, and real-time data streamed from producing wells.

- Performance reporting and analysis—KPIs, such as sustained casing pressure, well barrier element impairment, failed integrity test, open anomalies, and wells deviating from corporate or regulatory standards. Use of a “traffic light” or similar visual metaphor for indicating performance against plan/limits. Statistical analysis to understand datasets of increasing size and complexity and enable processes, such as predictive reliability. Visualization tools for well barriers and well barrier elements (WBE).

- Case management—A uniform approach for analysis and risk evaluation for investigation and follow-up activities for anomaly events. Includes overall risk ranking as part of the case management capability of well risk status. A full set of records of status/condition of WBE, tests performed, deviations, RCFA/FMECA, change to well integrity and the result of corrective actions; standard data workflows help support major work processes.

- Technology—A technology platform to deliver reporting, analytics capabilities and the complex integrations with engineering and business systems. Library access to a wide variety of WI reference documents: company policies, regulatory well policies and reporting requirements, well construction data. Strong security control, via integration with corporate authentication systems. Knowledge management capabilities for sharing lessons learned to distributed workforce.

- Data management—Policies and procedures to utilize existing standards for equipment naming, security and retention. This includes common templates for processes, such as the addition of new or replacement equipment or asset start-up.

FUTURE DIRECTIONS

The convergence of several factors—heightened awareness of WI across multiple stakeholder groups, the emergence of WI as a technical discipline in its own right, and increasing global well populations with recognized WI issues—has clearly resulted in increased industry efforts to aggressively manage WI. This trend will continue, with increased emphasis on managing WI as a distinct strategic goal. Organizational models will better clarify and enhance the key roles in managing WI, with increased reliance on technical specialists in WI, either at the central or regional level.

The development of a more robust, risk management process will result in increased emphasis on collecting better-quality data, to support a more quantitative and precise risk analysis. The development of fit-for-purpose data management systems will be augmented with streaming data, driven by the ongoing explosion in sensor deployment (Internet of Things). Industry groups, such as NORSOK, will include more detailed data management specifications to help with the exchange of data and standardization of reporting. Material specifications will increasingly be available from vendor catalogues hosted on cloud systems. There will be greater use of integrated system modelling (reservoir, wellbore, topsides). Cross-industry collaboration will require industry convergence on data standards for integrity data interchange. The fit-for-purpose suites will increase in sophistication and provide simulation/modelling capabilities for deeper analysis.

While much progress has been made in improving WI workflows, methods and organizational capability, the future will see these trends continue to grow and mature, as the industry recognizes the importance of managing well integrity. ![]()

- Coiled tubing drilling’s role in the energy transition (March 2024)

- What's new in production (February 2024)

- Using data to create new completion efficiencies (February 2024)

- Digital tool kit enhances real-time decision-making to improve drilling efficiency and performance (February 2024)

- E&P outside the U.S. maintains a disciplined pace (February 2024)

- U.S. operators reduce activity as crude prices plunge (February 2024)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)