Changing the landscape of BOP testing

The Macondo incident focused international attention on well safety and the important role blowout preventers (BOP) play in offshore drilling operations. In most cases, the BOP is comprised of a redundant stack of valves used to control and monitor operations. A choke manifold is part of the control system and responds automatically to an unforeseen event (kick) to lower pressure in the wellhead. When properly installed and maintained, the BOP and choke manifold effectively manage extreme and varied pressures by controlling flow. The system ensures well integrity and the safety of the offshore crew and the surrounding environment.

In the Gulf of Mexico (GoM), the Bureau of Safety and Environmental Enforcement (BSEE) requires the BOP and choke manifold to be inspected and pressure tested every 14 days during drilling operations. When using a standard analog pressure testing system, drilling operations are shut-down for approximately 24-48 hr. The analog pressure sensor plots data on a paper chart which is then subjectively assessed by rig-site personnel, Fig. 1. If a test fails, the crew is responsible for determining the root-cause of non-compliance. To meet the strict BSEE testing and maintenance requirements, many operators hire a team of pressure testing experts.

TECHNOLOGY RESPONSE

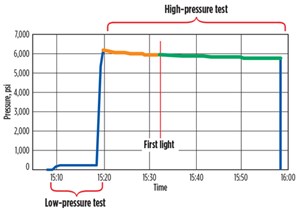

While working for a common client, Offshore Technical Compliance (OTC) and Hecate Software, decided to form a partnership to develop a cost-effective digital pressure-testing software that would provide reliable analysis combined with expert compliance oversight. Working together, the companies produced GREENLIGHT (Fig. 2), a digital pressure software that is BSEE approved for low- and high-pressure BOP tests. Essentially, GREENLIGHT (GL) tells rig-personnel when a test is in compliance with BSEE requirements.

The software program is driven by algorithm-based technologies to provide accurate pressure testing and reporting capabilities. GL was first designed for low- and high-pressure BOP testing, referred to as “analysts.” Analysts can be developed and customized according to an operator’s specifications by their in-house IT programing team, thus protecting specific intellectual property.

Expert compliance oversight and well-control test assessment can be provided at the rig-site by OTC’s staff of experienced petroleum engineers, many of whom are former BSEE inspectors. This on-site expertise can identify potential areas for improvement and reduce or eliminate costly delays and potential safety issues.

NEW STANDARD IN PRESSURE TESTING

GREENLIGHT is an algorithm-based system specifically designed for pressure testing. A computer is used to collect data then objectively perform pressure testing. The analysts can save time by continuously analyzing data independent of fluid volumes, type and test pressures. This analysis provides an accurate and safe assessment of pressure integrity. GL produces a continual and secure digital record of all testing activity from start to finish. For BOP testing, low- and high-pressure analysts are implemented to determine outcomes. This process provides companies, especially those operating with synthetic or oil-based muds, valuable real-time digital output and predictive analysis, which can save time during high-pressure testing.

NO BENCHMARKING REQUIRED

GREENLIGHT’s high-pressure analyst incorporates a mathematical model of pressure versus time that is applied to high-pressure tests independent of fluid composition. Adapting the model to a limited set of early pressure versus time data allows future behaviors in the same test to be accurately predicted. Thus, each pressure test is evaluated on its own merit. The points in one high-pressure test are not compared to the points in an earlier test because the algorithm does not require benchmark testing for a baseline reading. This, coupled with GL’s restart after every pump-up, abbreviates overall testing time.

EFFICIENCY AND ACCURACY

The system’s user-friendly interface allows for easy on-site annotations and test associations, analysis and reporting. Once testing begins, there is a secure and uninterrupted digital record of all pressure data, ensuring a comprehensive job history. Test results can then be reviewed by OTC’s on-site team of engineers and safety professionals to ensure compliance and documentation accuracy. GL generates clear and concise reporting, including integration of surface and/or subsea pressure testing plans and schematics.

Additionally, 24/7 support can be accessed through OTC’s call center and operations team. OTC also has a training center, which can be used to instruct new users and provide software demonstrations and support.

LOW-PRESSURE TESTING

A significant amount of testing has been performed to ensure GL’s results for low-pressure tests are in agreement with the findings of field assessments using circle charts. The basic GL BSEE approved low-pressure test uses a non-predictive algorithm to monitor the BOP test. A passing test is reported if the following criteria are met:

- The duration of the test must be at least five minutes long.

- All measured pressures must be above 200 psi.

- All measured pressures must be below 300 psi.

- If during the initial pump-up, the pressure exceeds 500 psi, the test must be terminated and rerun from zero.

- The slope at the end of the test will be declining no faster than 3 psi/min.

- The slope anywhere within the test will be declining no faster than 5 psi/min.

- The second derivative of a curve fitted to the data will be no less than -2 psi/min. anywhere.

All of the settings above are parameters of the basic BSEE low-pressure analyst and can be adjusted, with approval from BSEE, to meet the needs of a specific client. For example, the measured pressure range could be adjusted to accommodate testing between 250 psi and 350 psi.

HIGH-PRESSURE PREDICTIVE ALGORITHM

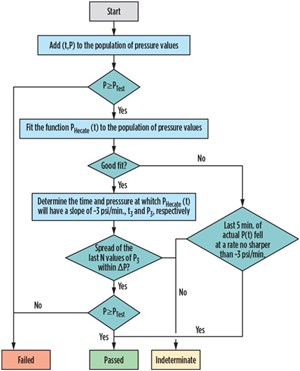

The software’s high-pressure analyst uses a prediction algorithm that fits a proprietary curve to the values of time and pressure measured during a high-pressure decline, Fig. 3. The algorithm works independently of fluid type, volume or temperature. However, the time require to make a prediction is dependent on the above three factors. The algorithm begins anew with every pump-up, which initiates the following steps:

- The algorithm attempts to fit a curve to measured pressure points in a high-pressure test each time a new point is measured (typically once per second).

- After each fit, if successful, the time and pressure at which the curve will have a slope of -3 psi/min., referred to as t3, P3 is calculated.

- After consecutive values of P3 fall within a small pressure window, the basic BSEE high-pressure analyst will make a prediction regarding the outcome of the test, passed or failed, depending on whether the final prediction is above or below test pressure, respectively.

- Included in the basic BSEE high-pressure analyst is the ability to classify tests using non-predictive algorithms that strictly adhere to BSEE requirements.

An explanation of GL’s high-pressure test analysis is shown in Fig. 4. Each high-pressure test can have multiple pump-ups. In this case, we consider the data following the final pump-up. Before GL makes a prediction, an orange light is displayed on the top left side of the pressure curve. When GL predicts a “good” test, a green light displays on the top right side of the pressure curve. Time savings are measured relative to the first green light, or “first light.”

CASE STUDY

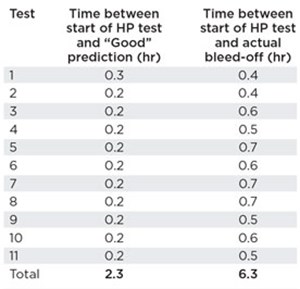

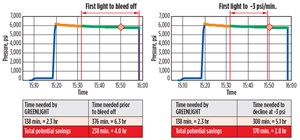

From April through October 2015, GREENLIGHT was run parallel with circle chart analysis during tests of the choke manifold on a deep water rig in the GoM for comparison purposes. GL predicted “good” results for all 11 tests in agreement with the circle charts. The total time required to obtain the data, 11 low and 11 high-pressure tests, as well as some time troubleshooting was 11 hr. Two methods were used to determine potential time savings: 1) first light to bleed off; 2) first light to -3 psi/min. Table 1 shows that GL could have shortened testing time by approximately four hours using the first light to bleed off method. This potential time savings would result from: a.) predictive ability of GL’s high-pressure analyst; and b.) ending the test earlier as soon as the digital analysis determined that a flat line had been achieved (i.e., a decline rate of -3 psi/min.).

Additional time versus pressure analysis was performed on each of the 11 tests to chart the potential time savings and fully understand the advantages of using GL’s predictive software, Fig. 5.

Method 1: Time from the first “green light” to actual bleed-off. This head-to-head comparison was possible because GL was run parallel with circle charts and circle charts were used to end the test. This resulted in an actual assessment of field behavior and identifying 4.0 hr of potential time savings. Method 2: Time from first “green light” to decline at -3 psi/min. This method can be calculated for any dataset and does not require actual bleed-off data because a -3 psi/min. point can be predicted. The potential time savings was calculated at 2.8 hr.

ADVANTAGE OF DIGITAL PRESSURE TESTING

Offshore Technology Compliance and Hecate Software’s suite of digital BOP testing software offers the industry reliable pressure analysis and compliance oversight. The GREENLIGHT system uses proprietary algorithms to conduct, analyze and document a wide variety of pressure tests and does not require benchmarking for a baseline reading, which reduces overall testing time.

The software has a user-friendly interface which allows for easy onsite annotations and test associations, analysis and reporting. GL is supported by a staff of registered petroleum engineers and compliance experts that are available 24/7 and can be reached at OTC’s call center. The digital BOP testing system removes the subjectivity involved with interpreting conventional chart recordings and provides accurate documentation while saving operators rig-time while reducing NPT. ![]()

- Coiled tubing drilling’s role in the energy transition (March 2024)

- Advancing offshore decarbonization through electrification of FPSOs (March 2024)

- Subsea technology- Corrosion monitoring: From failure to success (February 2024)

- Digital tool kit enhances real-time decision-making to improve drilling efficiency and performance (February 2024)

- E&P outside the U.S. maintains a disciplined pace (February 2024)

- U.S. operators reduce activity as crude prices plunge (February 2024)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)