Intelligent Well Technology

Optimizing reservoir performance with intelligent well technology

With key benefits of maximizing production rates and reserve recovery, industry can well afford investments in designing more-widespread intelligent well applications

Michael Konopczynski and Arashi Ajayi, WellDynamics International Ltd.

Following an introduction to background/ benefits of intelligent well technology (IWT), principal article sections describe: 1) field development applications; 2) adding value to assets with IWT; 3) how to approach field development planning; 4) application of reservoir simulations to assess development options; and 5) creating value by facing and coping with uncertainty. The conclusion summarizes intelligent well (IW) benefits, predicting they will survive today's business environment due to their positive economic performance potential.

INTRODUCTION

The upstream petroleum industry is struggling with the challenge of maturing assets, dwindling reserves, evermore challenging exploration environments, an aging workforce, abdication of expertise and, to top it off, financial markets looking for quick returns on their investments. These forces can, at times, oppose each other and industry's long-term success. How then can the IWs venture make inroads in the business to succeed and survive as a mainstream technology in this environment?

IWT is not new. The first well completion featuring permanent monitoring and the ability to control flow at the reservoir, the patented SCRAMS system, was installed in 1997. After six years, over 185 intelligent well systems (IWSs) have been installed worldwide by a number of suppliers and service companies. Some forums have estimated the IWS investment by service/ supply companies at close to $1 billion.

For IWT to financially survive, it must cross the market chasm from innovators and early adopters to majority buyers. In plain terms, intelligent completions must be installed not just on a trial basis in singular applications, but also in multiple wells as an important and integral part of field development. The good news is that this finally appears to be happening – although at a slower pace than many investors would like.

IWT is a key building block of real time reservoir management. By placing sensors and control valves at the reservoir face, teams of petroleum engineers can monitor reservoir and well performance in real time, analyze data, make decisions and modify the completion without physical intervention, to optimize asset performance. A commonly accepted definition of an intelligent well is: “One that allows control of flow into or out of the reservoir without physical intervention, with or without downhole sensors and monitoring.”

The challenge is to lower development cost and maximize reserve recovery as quickly as possible. Operators are looking to IWT to improve project performance for complex, challenging field developments.

FIELD DEVELOPMENT APPLICATIONS

Intelligent wells have many applications – principally the ability to actively manage the reservoir recovery process, which is especially important for secondary waterfloods or tertiary EOR projects. IWs can control the distribution of water or gas injection in a well between layers, compartments or between reservoirs. They can restrict or exclude production of unwanted effluents (water and/or gas) from different producing zones in a well. As a result, the operator can manage where it injects water or extracts oil to mobilize unswept reserves. This is particularly important for wells with complex architecture, e.g., extended reach, long horizontal or multilateral wells, and for reservoirs characterized by high degrees of anisotropy, heterogeneity or compartmentalization.

In 2001, the UK Department of Trade and Industry commissioned a study to identify future opportunity for North Sea reserve development. Many accumulations have been discovered which are too small or too marginal to be developed on their own. However, many such reserves are stacked, or in close proximity to others. Sequential exploitation does not produce the oil fast enough or in great enough volumes to be economic with conventional development methods.

The solution to this problem is to commingle the uneconomic reserves. IWT addresses reservoir management and regulatory concerns with controlled commingling by providing individual zone control, and the ability to prevent crossflow and allocate flow to each individual reservoir.

In the simplest of terms, using IWT is like moving surface production chokes and manifolds downhole, Fig. 1. Capital investment can be reduced by decreasing the number of wells and the infrastructure needed to exploit multiple reservoirs. The result is accelerated production, reduced operating expenditure and the ability to sustain production better than sequential production or multiple well scenarios. These opportunities abound in the Gulf of Mexico, West Coast Africa, and in most hydrocarbon basins around the world.

|

Fig. 1. Intelligent commingling of reservoir layers.

|

|

There are many more niche applications for intelligent wells, such as:

- Controlling pressure drawdown to ensure wellbore stability

- Compositional blending from different reservoirs

- Controlling dump floods

- Connector wells

- Gas lift and auto-gas lift, and

- Intervention reduction or remote control.

Despite technical appeal of these ideas, the fundamental applications for IWs remain: 1) control of water (or gas) injection distribution along the wellbore in injection wells; 2) control or exclusion of effluents along the wellbore in production wells; and 3) acceleration of production by commingling. These are the applications which operating companies should focus on when looking to increase asset values with intelligent wells.

ADDING VALUE TO AN ASSET WITH INTELLIGENT WELLS

To date, most IW applications have been in offshore platform and subsea installations; and, to a large extent, these are driven by the economics of avoiding future well intervention costs. Yet, since IW inception, increased reserve recovery and accelerated production have been recognized as key value drivers for IWT adoption. Even today, petroleum engineers have difficulty justifying IWs based on improved recovery and accelerated production. Why?

There are a number of reasons why it has been difficult to justify widespread IW use for projects based on net present value and increased hydrocarbon recovery. Lack of reservoir simulation tools that are IW friendly is often quoted as a key factor, but lack of analogous projects, concerns about long-term reliability, and uncertainty about reservoir performance, especially early in a development, also impede the technology adoption.

However, one of the biggest impediments to adoption of IWT is the focus on short-term financial performance. “Intelligent wells cost too much,” is a common lament heard whenever operating companies and suppliers get together. The response, “But you haven't considered the value they bring” often falls on deaf ears – and for good reasons, as noted here.

While financial sanction of major projects still hinges on net present value, return on capital employed (ROCE) is increasingly important when it comes to investment decisions, and the easiest way to improve ROCE is to reduce the amount spent up front. Shareholders are focused on the immediate value of a company. Chief financial officers have little appetite for adding costs to a project by adding intelligent wells, no matter what the long-term benefits are.

Armed with this knowledge, the asset manager should look not only to the long-term value contribution of IWs but, more important, how IWs can help them reduce total project capital investment. This means that the same or better asset performance must be realized by fewer IWs than the base-case development plan with conventional wells.

One method to reduce the number of wells required to develop a structure is use of extended reach horizontals, multi-laterals or commingled completions. The challenge to taking this step is monitoring and controlling downhole fluid movement. IWT can leverage wellbore architecture to reduce the number of wells required to develop an asset. By offering interventionless downhole control, significant operating expense can be reduced, particularly in the offshore and subsea environment. An additional windfall is that, by reducing or eliminating physical interventions, the risk of safety incidents is reduced. And the environmental factors of reduced development surface footprints cannot be ignored.

Finally, with downhole sensing and accurate data acquisition, the operator can achieve a better understanding of the reservoir/ recovery process, and can use this knowledge to make better and more informed operational decisions faster. We call this “concise reservoir management.” But it takes more than just downhole sensors and data acquisition to complete the circle. Interpretation and modeling, option analysis, workflow and decision processes are all part of the chain of real-time reservoir management. The dividends are better utilization of asset infrastructure, reduced effluent production, accelerated production, improved hydrocarbon recovery, and better selection of infill well locations and numbers of wells to efficiently develop an asset.

FIELD DEVELOPMENT PLANNING TOOLS

Field development planning is triggered: 1) when new fields containing commercial and viable hydrocarbon volumes are discovered; 2) when there is a significant discrepancy between predicted and actual performance for existing fields; or 3) when new technologies are considered to increase reserve recovery from mature fields. The plans address different development options relative to key geologic/ reservoir uncertainties within the context of satisfying overall objectives. This is where decisions are made on the amount of flexibility that should be built into the field development plan and how this should be done. The decision process requires a clear understanding of project performance sensitivity in the realm of the uncertainties.

IWT is a powerful tool that can help manage a wide spectrum of subsurface uncertainties or challenges often encountered in field developments. Some of the challenges may include: impact of drive mechanisms on recovery, effect of spatial distribution of properties on injection or production profiles, or influence of other factors such as aquifers or reservoir compartmentalization. Choosing the appropriate IW solution based on understanding the reservoir challenges can make a big impact on project economics.

Assess basic reservoir engineering first. To justify the use of IWs in a development project, the first inclination may be to immediately jump to a reservoir simulation. However, the best place to start this process is not to go to the simulator, but to use good petroleum engineering judgment. The reality is that, early in field development life, there are so many uncertainties about the reservoir and its geology that estimates of the incremental recovery efficiency increase from IW implementation pales in comparison to the error bars in recovery efficiency associated with reservoir uncertainty. As such, any attempt at deterministic evaluation becomes relative.

Some fundamental questions should be asked to determine the applicability of IWs to a field development project, for example:

- Will pressure maintenance be required? Will waterflood or gas injection be required?

- Is the reservoir compartmentalized? Is it layered?

- Is the reservoir significantly heterogeneous? Are there significant differences in permeability between layers?

- Is there an active aquifer or a gas cap? Is there a significant chance of water or gas coning?

- Will reservoir development benefit from use of horizontal or multi-lateral wells?

- Are there underlying or overlying marginal separate reservoirs that could be exploited by commingling?

If the answer to one or more of the questions is yes (particularly in combinations of questions), then you probably have a pretty good case to look at IWs for field development. As previously mentioned, the most important IW applications are to control influx of water (or gas) in a production well and water distribution in an injector.

It does not take a reservoir simulation to tell you that if you are exploiting a thin oil rim with long horizontal wells in a highly heterogeneous or compartmentalized reservoir, you are likely to see water or gas breakthrough in one part or another of the wellbore, eventually. Other wells in analogous reservoirs, or existing conventional wells in the same reservoir, can probably give a sense of whether production problems are likely to be experienced. The litmus test is the comparison of IWs to alternate conventional contingency actions, to economically/ viably address the production problems.

What has been described here is the first step in a screening process to determine the applicability of intelligent wells to a field development plan. It requires a degree of understanding of the geology, petrophysics, structure, recovery process and development options for an asset – and an understanding of what is uncertain about these issues. Hence this type of exercise is best done in a petroleum and operations team environment.

Define IW objective and value. The second step in the screening process is to define clearly the objective of the intelligent well and hence the functional requirements. This leads to conceptualization of the intelligent completion design. Modeling of the intelligent completion design for inflow/ outflow performance (nodal analysis) and wellbore hydraulics is required to ensure that the completion has the flow capacity and lift capability to fulfill functional requirements over the full spectrum of anticipated operating conditions. Optimization of the intelligent completion design is done using the modeling capability.

The third step is to attempt to quantify the value of IW application to the field development process – we just aren't comfortable with any field development these days without a reservoir simulation! A word of warning: this is a difficult process. As pointed out, the degree of uncertainty about recovery process and reservoir characteristics are likely to have a bigger impact than IW benefit measurable with a reservoir simulator. Scenario and Monte Carlo modeling or other stochastic methods will improve statistical validity of the simulation, and should be used where possible; but beware of simplistic, deterministic evaluation of the intelligent well case.

The screening and design process described is illustrated by the flow chart in Fig. 2. The process will benefit from several iterations of the overall process and loops within the process and, as such, should be started early in the field development planning exercise.

|

Fig. 2. Intelligent completion screening/ design process.

|

|

RESERVOIR SIMULATIONS

Numerical reservoir simulation is used to assess the impact of subsurface uncertainties on development options. To this end, incorporating the functionalities of IW systems (IWSs) into the reservoir simulator improves the analysis, helps selection of the appropriate IWS, and speeds solution optimization.

A reservoir model of an IWS must effectively address the following challenges:

- Well representation

- Cross-flow for accurate volume/energy balance

- Downhole choke performance, and

- Control functionality.

The well representation challenge is related to how well architecture is translated into a flow network in the simulator. One solution is to adopt a nodal network approach, with the physical components located between nodal points and their fluid dynamic performance represented by mathematical algorithms. A typical configuration and its model representation, Fig. 3, makes it easier to independently evaluate nodal point performance.

|

Fig. 3. Nodal representation of intelligent well system.

|

|

The vital component of an IWS is the downhole interval control valve (ICV). The ICV allows independent control of each zone as, and when, required to maximize production. The ICV is represented in the simulator by a choke positioned at the appropriate reservoir depth. The pressure drop across the choke is dependent on fluid composition, flowrate and choke position, and may be characterized by empirical data or mathematical correlations.

The control function defines the ability of the simulator to change settings of the defined IWS to deal with observed reservoir behavior. Control can be achieved either in static or dynamic mode. Static mode refers to the manual optimization process where the simulator is first run to the desired end of simulation time.

Results from the first run are analyzed for potential production problems, and the time of occurrence for such problems is noted. In subsequent simulation runs, manual adjustments are made to the well settings at the time of interest to mitigate the observed problem, and the simulation is run again. This process is repeated for as long as it takes to achieve optimal results. Apart from this approach's inefficiency, it is also time consuming, especially when dealing with large models or large numbers of wells.

A better control function is the dynamic mode. This involves building a logic algorithm or “intelligence” into the simulator that enables it to control choke settings at each time step based on pre-defined objectives (as you do in the field). The dynamic approach uses an optimization routine that checks performance of each zone as the simulation progresses and restricts or opens zones accordingly to optimize total well production.

Integration of the reservoir simulator with a dynamic control function technique enables use of the simulator as an efficient field development tool to quantify IW system benefits. This process also allows the engineer to choose the appropriate system that covers the range of identified reservoir uncertainty. The control method described is analogous to expected field operations and can be used as informed input into field surveillance guidelines.

CREATING VALUE BY COPING WITH UNCERTAINTY

Uncertainty about geology and reservoir performance, expenditures and tax regimes, and oil price can undermine validity of results from reservoir simulation and deterministic economic assessment of development projects. The typical log-normal distribution of reservoir parameters such as porosity, permeability and saturation opens a wide variety of potential outcomes every time a well is drilled in a development project and, for the most part, we have great difficulty predicting what the outcome will be. Uncontrollable events and outcomes can have a devastating effect on project economics.

There is little we can do as petroleum engineers about oil price, taxes or fiscal regimes; however, there are steps that can be taken to both evaluate and address uncertainty when it comes to reservoir performance issues. Including intelligent well technology in reservoirs characterized by variability is like buying an insurance policy or an option against uncertainty. The operator makes an investment early in the development to provide the flexibility to respond to unanticipated behavior and reservoir/ well performance.

It is important that an IW not only has the ability to sense and transmit physical information about what is happening in the wellbore and the proximal reservoir, but also the ability to control fluid flow into and from the wellbore over its length. It is the flexibility in configuring the completion and controlling downhole production/ injection processes, without conventional intervention, that allows the operator to respond to changing conditions in reservoir performance, and to reduce the impact of reservoir performance uncertainty.

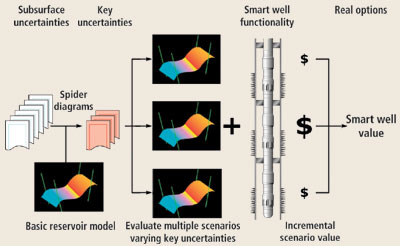

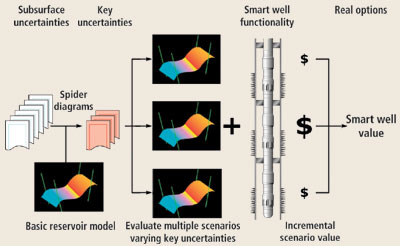

To assess the expected return from our projects, we must consider stochastic methods such as Real Options rather than more deterministic methods such as discounted cash flow valuation, Fig. 4. The challenge is to sift through various field development options and understand uncertainty and risk associated with each project. Intelligent wells can mitigate the risk, making potential portfolio killers less risky, and making potential missed opportunities viable candidates.

|

Fig. 4. Stochastic evaluation process for intelligent wells.

|

|

The bottom line is that IWT should be considered with the company's portfolio in mind. IWT has the potential to mitigate risk through active reservoir management, helping balance rate of return within a portfolio of projects, and ensuring a better probability of receiving the return you expected.

CONCLUSION

In summary, the key benefits of intelligent wells in a field development process are the ability to: 1) optimize production rates and reserve recovery; 2) minimize development CAPEX and OPEX; and 3) manage the reservoir more effectively. With industry intelligent well experience approaching 200 wells, the ability of IWs to meet operator objectives is demonstrated in the number of repeat buyers and multi-well intelligent-field development projects now being planned/ executed. The signs are positive that intelligent wells can survive in today's business environment, and improve economic performance of those companies that use them in their development projects.

THE AUTHORS

|

|

Michael Konopczynski is the manager of reservoir solutions and commercialization at WellDynamics International Ltd., Aberdeen, UK. Prior to joining WellDynamics in 2001, he was with Shell Canada in a variety of production engineering and technology roles for 20 years. His assignments included projects for steam-assisted thermal recovery, CO 2 -enhanced recovery, deep sour gas development, and gas-condensate developments in Canada, the US and, most recently, Oman. Contact: mike.konopczynski@welldynamics.com

|

|

Arashi Ajayi is a reservoir engineer with WellDynamics, Spring, Texas, where he is responsible for reservoir simulation and support. He joined Shell in 1994 as a reservoir engineer, and he joined Well Dynamics in 2002, resulting in over nine years of experience to date in performing reservoir engineering studies and implementing reservoir development projects in Africa, Europe and the US. Contact: arashi.ajayi@welldynamics.com

|

| |

|

|