Pressure pumping advancements give operators a competitive edge

As companies continue to push their equipment harder and pump longer hours, nonproductive time (NPT) threatens profitability. This contributes to interest in the simul-frac completion technique. Simul-frac operations are attractive, as they enable operators to complete more stages in less time. Rather than pumping one well at a time, the simul-frac completion technique allows companies to pump two horizontal wells at the same time with a single fleet—immediately doubling pumping time. This enables companies to minimize NPT and maximize lateral footage gains and savings to realize efficiency improvements by as much as 60%, according to Rystad Energy, compared to the zipper frac technique.

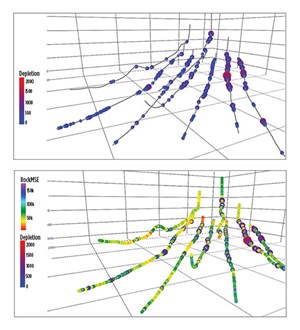

High horsepower. As pumping hours have increased to be nearly continuous—regularly clocking in at 18 to 22 hours (hr) per day—the need to increase performance while reducing NPT is evident. From an efficiency perspective, e-frac pumps offer a distinct advantage with maximum horsepower (hp) and minimal pumps. With high-horsepower capacity in a single unit, such as the 5,000-hp continuous-duty SPM™ QEM 5000 Pump, pressure pumping companies can experience the same level of uptime as with conventional spreads—and with far fewer pumps, Fig. 1. This high-horsepower density, running at 100% of road load 24 hr/day, means eight 5,000-hp pumps can match the output of 20 conventional pumps. High-efficiency (HE) frac technologies can be leveraged in simul-frac settings to realize even greater efficiencies and cost-savings.

Minimized maintenance. Near continuous-duty operations don’t allow much margin for NPT of any kind—including maintenance. This has given rise to pressure pumping equipment like the QEM Series. This new equipment is especially robust and specifically engineered to operate longer cycles with fewer maintenance intervals, while also withstanding irregular maintenance practices, due to field teams maintaining a complex variety of equipment. Improvements in pump frames and wear components help reduce frame cracking and bearing stripping for longer life, helping operators stay out of the red zone and reducing unplanned maintenance issues.

Working with experienced and technically skilled service providers can help pressure pumpers identify the sweet spot between inadequate maintenance and excessive spending, which can cause a decrease in valuable uptime. Partnering with SPM™ Edge Services, for example, provides engineering-driven expertise that guides field crews to gain the full benefit of longer cycle equipment, so they can push harder and make bigger gains.

Longer-lasting consumables. Reduced maintenance not only lowers NPT, but it also lowers costs. As consumables represent one of the largest maintenance expenses on a frac site, and their replacement impacts pumping hours, identifying ways to minimize fluid end maintenance can help oil and gas companies achieve greater efficiencies. Employing new seat technology like the SPM™ EdgeX™ Carbide Seat (Fig 2), which is field-proven to increase seat life an average six times compared to conventional seats, can substantially reduce the downtime caused by field changeouts, as well as expenses. In addition to its enhanced longevity, the EdgeX’s carbide-reinforced seats protect high-wear areas while fitting standard taper fluid ends.

Maintenance and unexpected NPT are known to negatively affect pumping hours and profits. Significant technological advances and novel approaches to pad design can be leveraged—and combined—to significantly increase efficiency gains in the field. The performance improvements operators can realize by employing one or all of these technological advancements can make a difference that’s reflected in companies’ bottom lines.

Related Articles- Annular safety valves advance flexibility, reliability and safety in completion operations (July 2024)

- Aramco's upstream digital transformation helps illuminate the path toward excellence (June 2024)

- Adopting a holistic approach to cybersecurity (March 2024)

- Embracing automation: Oil and gas operators leverage new operational efficiencies (May 2024)

- Dawn of a new day in completions (May 2024)

- Extracting resources from the Earth’s crust using multi-stage, fraced horizontal wells: First gas, then oil, now heat (May 2024)