Meeting the demand for positive free cash flow through efficient drilling scheduling

Digital transformation initiatives are a hot topic and are mainly aimed at adopting the latest advances in digital technology to transform a company’s operations and replace older technology. Successful transformations result in improvements in organizational agility, a higher level of efficiency, and cost savings. Unfortunately, though, many such initiatives don’t meet expectations, or end in outright failure, so it’s critical to think carefully about what “digital transformation” actually means, and what it requires of company management.

Digital transformation means looking carefully at a company’s business goals and then considering exactly what kind of technology would prove beneficial and support achievement of those goals. As well, the existing business processes need to be examined critically, and changed if need be. Too often, the cart is put before the horse: the decision is made to implement a specific type of technology, and then management seeks a home for it within the complex business processes that are already in place. This risks not only misalignment of expectations for everybody involved but may also actually work against a successful outcome.

Retail shows the way forward. In the retail sector, one company exemplifies the transformation of business via the application of modern technology and digitization more than any other: Amazon. Once a staid business, delivery logistics is now the frontline of a tectonic shift that’s taking place around the world. Since its inception in 1995, Amazon has become one of the biggest and most influential companies in the e-commerce market. The secret behind their success has been their ability to adapt to the constant changes in shopping and technology trends, such as the rise of the Internet and ubiquity of digital devices, and to ensure that their entire organization moves continually in the same direction. The same thinking needs to be applied to the oil field.

Investing in digital transformation as a cash-flow lever. Recently, larger oil companies, such as BP, Shell, Equinor, and Total have stated their aims to invest significantly in becoming “digital” companies. Shell estimates that using AI-centered digital software for its upstream and oil production business will drive $1-2 billion in revenue, while BP expects “billions of dollars” of benefit from digitalization. More specifically, Equinor forecasts a $3 billion improvement in free cash flow due to digitalization in 2020-25, while Repsol estimates a $1.7-2.2 billion cash flow bump from digitalization by 2022 (over half coming from their exploration and production division). Both companies have announced they are well on their way to meeting these targets.

UPSTREAM SCHEDULING

With all this talk about the need for E&P companies to transform their operations to refocus on investor and market demand for positive free cash flow, applying an appropriate digital transformation strategy to obtain the expected benefits sounds promising. But where to begin? An obvious place is in streamlining drilling programs and their associated logistics: this can play a major role in improving a company’s position and ability to react rapidly to industry and market changes. And this leads to the need to think about the importance of scheduling and how it’s done.

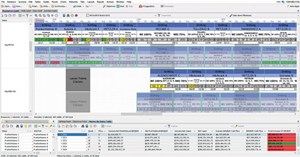

Why is scheduling important? The schedule represents a model of how the organization is working now, and how it will work in the future, Fig. 1. The schedule should show how efficient drilling operations are, and more importantly, how those operations will spend and make money. The way in which the schedule models the real world, in terms of resources available, the activities that they must carry out, and what constraints may influence how and when the resources do productive work, is key to building an accurate model of operations and costs over time. As well, the scheduling process should be agile and flexible, because the operational environment changes every day in planned and unplanned ways. This means that decisions must be made rapidly to ensure that everything keeps running smoothly.

Too often, though, scheduling is relegated to second tier thinking by many operator management teams, and the tools used to manage schedules on an ongoing basis are given little thought and attention. Operators using simplistic software tools, like Microsoft Excel or Microsoft Project, may be delivering producing wells, but at the cost of a scheduling business process that is sub-optimal, that requires a great deal of unnecessary manual work, and that doesn’t provide insight into the impact of changes to aid in decision-making. Too often the scheduler must wrestle not only with their primary scheduling tool, but also with multiple other tools and spreadsheets to keep everything synchronized and operations aligned. More importantly, key constraints won’t be taken into account because there is simply no way to represent them in these tools, and since the possibility of inadvertently introducing errors into the schedule is high (because the entire process is manual and the model of operations logic is in the scheduler’s head), the likelihood of translating these errors into drilling operations is also high, and this can lead to delays that extend cycle time, overlapping activities, unexpected costs, and overall poor performance.

Applying new technology to scheduling. The selection and use of an effective and modern scheduling tool will make all the difference to decision-making and efficiency, since the tool will report on important key performance indicators very rapidly, Fig. 2. Additionally, the schedule will be more accurate, capturing all the constraints present in the operational world that influence efficiency. And by optimizing how activities are scheduled and paying close attention to how money is allocated to resources as well as how it’s spent over time, operators can achieve greater positive cash flow.

Consider, for example, what happens when integrated schedules are used to manage drilling programs. Integrated schedules bring resource and activity information from multiple disciplines (drilling, completions, facilities, maintenance, logistics) into a single source of scheduling truth, and this enables questions to be answered and decisions to be made with full information available to all drilling team members. The old way of working, with different disciplines managing their own operations with silos of data, simply isn’t effective and has been abandoned by more progressive operators. And here is where the digital transformation process really pays off: eliminating the barriers between disciplines and their use of data, pulling that data together for scheduling purposes, and ensuring that much-needed accurate schedule information is available to all those who need it in a timely manner can create a step change in the way that the operator works.

This point of view was endorsed in a recent McKinsey report titled “An operator’s guide to transforming E&P”, in which the author states, “Refocusing on cash means operators must squeeze every dollar from their assets while simultaneously retooling for the new era. Unlocking cash will take more than volume growth and G&A reduction; it will also involve rethinking capital allocation and creating long-term value from both technical functions—such as drilling—and organizational functions—such as logistics.”

Harnessing the power of a computer to carry out the laborious scheduling tasks (such as aligning the schedule with business goals) frees the scheduler to focus on their actual job rather than tweaking spreadsheets and trying to keep multiple applications synchronized. All factors that are critical to success in any drilling program (minimizing cycle time, meeting lease obligations, understanding the potential for well interference and taking steps to avoid or mitigate it, for example) are handled by the scheduling tool, rather than the scheduler, and in much less time. Even if needed data is in another application. a modern scheduling tool will provide an integration function that enables easy and rapid import of that data, so that the scheduler can be confident that their decisions and recommendations are based on reliable information. But that’s not all:

with 21st century scheduling software, the scheduler is able to apply their expertise and judgement to fine tune drilling operations, answer questions rapidly, and provide higher value to the organization.

A critical need in E&P organizations is the ability to create and evaluate multiple schedule scenarios to answer, “What if?” questions (“Should we add a rig in the fourth quarter”? “If we want to bring more drilled uncompleted wells online by the end of 2021 can we do it in a cost-effective way?”). Balancing program costs against expected production is also vital, and so operators need rapid and accurate scenario comparison capabilities to make the right decisions. Using 1990s technology, like MS-Excel, doesn’t meet the requirements of modern operations: there is no way to create scenarios easily and rapidly, let alone compare them. But modern scheduling tools incorporate comprehensive scenario capabilities that make this job easy and greatly increases the productivity of the human scheduler.

Leveraging AI to reduce gaps in schedules and free up cash. Over the past few years, capital providers pushed hard for companies to show greater financial discipline and faster returns. The industry responded and has become more efficient by leveraging technology in pursuit of a free cash flow positive production model. This push from investors has become so strong that even large international exploration and production companies are investing in new technology to improve operations. How does this translate to the issue of scheduling? Modern scheduling tools leverage AI to automatically optimize drilling program schedules, dramatically reducing cycle times, and ensuring resources are used as efficiently as possible. Simple scheduling tools may show how individual resources are being used, but they don’t show how activities are related to one another over time, and where unwanted gaps appear in the schedule. These gaps are a drag on efficiency and cash flow, so they need to be found and minimized as much as possible. Today’s advanced scheduling tools will create optimal schedules that minimize gaps to reduce this non-productive time and lower costs. And because advanced scheduling tools provide insight into how money is being spent over time, it’s easy to predict cash flow and see how efficiently capital is being used to drive profitability.

Tangible benefits. The list of benefits that operators have obtained from a rethinking of their scheduling process as part of a digital transformation initiative are impressive. Some examples:

- Before adopting this new software, one large U.S. independent E&P company had eight engineers work for two weeks to create and evaluate scenarios that would enable them to lock in their quarterly budget. With AI-powered scheduling software, they required only one planning analyst, two engineers and two days to complete the exercise.

- A U.S. operator was experiencing schedule conflicts because their pre-spud, drilling, and completion schedules were separate and could not be easily integrated. This was causing permits to be obtained at the wrong time, construction, and completions to be out of synch with drilling, and major difficulties with long range planning. The operator estimated this was costing almost $2M/year. Using a more powerful modern scheduling tool and integrating their schedules saved more than $1.4M/year.

- A major oil company reported savings of over $5 million in the first three months of using an advanced scheduling tool. One of the reasons for their acquisition of the product was the ability to optimize rig movements, in a way that avoids unnecessary rig travel. The company had seen many instances of overlapping moves, along with rush movements, to ensure that their drilling program was proceeding as planned. Within three months of use, the company was able to rationalize their rig fleet use to the extent that they estimated a $5 million savings. They also reported a cycle time reduction from spud to first oil.

- An E&P company reported savings of around $1.5 million in people’s time, in the first three months of using a modern scheduling tool. Formerly the drilling team used MS-Excel to schedule operations, and this required a daily meeting of up to three hours with 20 people attending. After the new scheduling tool was brought into the organization the meeting evolved to a 4-person 15-minute daily session. The schedule was viewable by all attendees, the impact of changes was immediately visible, and questions about moving wells resolved rapidly.

The bottom line. Here’s a fast way to determine whether scheduling is working well in your organization, or whether it’s a suitable place to apply digital transformation. If you are a manager, think about the last time you asked your team to prepare a schedule scenario to help guide thinking about a significant change in your drilling operations. Did it take more than a day? If so, you need a better scheduling tool.

If you are a scheduler, do you spend more than 25% of your day working in spreadsheets, performing calculations, and updating information in multiple places? If so, you need a better scheduling tool. If you’d like to see how Actenum’s advanced AI powered scheduling software can help you to improve efficiency and meet the demand for positive free cash flow, contact us at info@actenum.com

- Digital transformation/Late-life optimization: Harnessing data-driven strategies for late-life optimization (March 2024)

- The reserves replacement dilemma: Can intelligent digital technologies fill the supply gap? (March 2024)

- Digital tool kit enhances real-time decision-making to improve drilling efficiency and performance (February 2024)

- Digital transformation: Digital twins help to make the invisible, visible in Indonesia’s energy industry (January 2024)

- Digital transformation: A breakthrough year for digitalization in the offshore sector (January 2024)

- Quantum computing and subsurface prediction (January 2024)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)