The road to net-zero: Baker Hughes' commitment to reducing oil and gas emissions

Q&A with Jeanne-Mey Sun, executive – energy transition and clean energy solutions, Baker Hughes.

Q: Jeanne-Mey, in a few words, could you please tell us how you see the future of the energy mix, and what Baker Hughes is planning in that scenario?

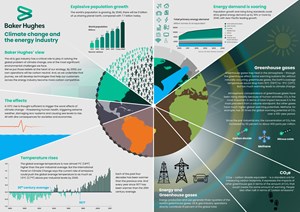

Although there will be significant growth in renewables, biofuels, and other alternative energies, oil and gas will also remain a significant part of the energy mix for the foreseeable future.

Increasingly, companies across the oil and gas landscape have begun to take steps to find and produce hydrocarbons more efficiently and with lower carbon intensity.

In January, Baker Hughes committed to achieve net-zero carbon emissions from its operations. This commitment includes a 50 percent reduction in CO2 equivalent emissions by 2030 (compared to a 2012 baseline), and net-zero CO2 emissions by 2050.

We are also committed to helping our customers and the oil and gas industry reduce overall carbon emissions through the adoption of new technologies. These technologies improve energy efficiency, reduce venting, flaring, and fugitive emissions, promote substitution toward cleaner burning fuels like natural gas, capture and store carbon dioxide, and provide energy storage solutions that can be combined with renewables.

Q: Could you please expand a little on how Baker Hughes is reducing its direct carbon emissions?

We have been focused on energy efficiency and reducing the carbon footprint of our operations for more than 10 years.

As a result, we have already reduced our carbon emissions by more than a third since 2012, including an 11%reduction in 2018, through a combination of energy efficiency projects, facility consolidations, logistics optimizations, and increasing use of renewable energy in our operations. We have also begun doing life cycle emissions assessments of several products and services, which will help us identify opportunities to reduce both our manufacturing carbon footprint, as well as that of our suppliers.

Some of the innovations we’ve deployed internally include natural lighting, energy efficient hardware, and building automation systems. Energy efficient windows and motorized shades further reduce solar heat gain and minimize glare.

We’ve also worked on employee engagement, launching hundreds of site-level facility energy “treasure hunts” and energy audits. These decentralized improvement efforts were a major contributor to our company’s 11% emissions reduction in 2018. Employees additionally receive special benefits for participating in vanpools and other programs aimed at reducing emissions from commuting. These initiatives are really encouraging and taking momentum.

Q: And for Baker Hughes’ customers: how are you helping them reduce emissions for upstream E&P operators specifically?

This year, we launched a carbon management consulting practice to help governments, energy companies, and the financial community understand and solve energy transition issues related to oil and gas resources, assets, and investments.

When you look at E&P: With advanced geoscience and petroleum engineering analysis, operators can optimize their fields, reducing their surface footprint with more efficient well placement, or even reduce the number of wells drilled.

We are focusing efforts on technologies designed to drill and complete wells more quickly, using less energy, with fewer people and logistical challenges. For example, during the production phase, highly efficient electric submersible pumps (ESPs) require less energy and can be digitally optimized. In addition, production chemicals reduce the amount of energy required to transport hydrocarbons in pipelines, helping cut emissions.

And for subsea developments: With modular production systems, subsea architecture can now be smaller, lighter and use less material than traditional subsea equipment. It becomes easier to deploy using smaller vessels. Interventions on modular designs are faster and require less energy.

All of this can add up to more sustainable field development—both on and offshore.

Q: Should tackling venting, flaring and fugitives be a priority?

Yes, venting, flaring, and fugitive emissions represent a very significant category of carbon emissions in the oil and gas industry and are therefore an important focus.

For example, we’ve been looking at converting flared field gas into electricity. There are more than 500 frac fleets across North America. The majority are powered by trailer-mounted diesel engines. Each fleet can consume up to 7 million gallons of diesel annually. Switching just one frac fleet from diesel to natural gas can reduce emissions by 24%, or 17,000 metric tons of CO2 equivalent per year. In addition, there are reduced fuel costs from buying and transporting diesel to the well site.

When gas must be flared, you need technology that provides highly accurate, near-continuous control of flare performance. We call this flare.IQ. It optimizes combustion efficiency, allowing operators to reduce flaring-related emissions and reduce the cost of steam production

Q: This is great news, that you are looking at this holistically and thinking about both environmental and economic benefits. Do you have a roadmap for the future?

The energy industry continues to develop new products and services that are pushing the frontiers of technology, and I believe the oil and gas industry will remain carbon competitive in the new energy economy.

We have, for example, a leading position in the global gas supply chain, thanks for our turbomachinery applications and therefore directly contribute to the world’s move toward cleaner-burning natural gas as a substitute for coal, diesel, and heavy oil.

The next generation of turbines will be capable of running on 100%hydrogen fuel. The first pilot installation of these new low-emissions turbines is already underway in Australia.

A number of forward-thinking operators have seen success in deploying enhanced oil recovery (EOR) using flare gas and captured CO2. Gas-injection EOR is an alternative to chemical recovery or artificial lift and it has the added benefit of potentially reducing carbon emissions.

I believe strong collaborative partnership will bring better outcomes.

We work in partnership with others to accelerate solutions for future generations. This includes progressing disruptive technology and innovation to increase the competitiveness of diverse global energy markets.

Recently, we announced a joint venture with C3.ai, a leading artificial intelligence software provider, to deliver digital transformation technologies at scale and drive new levels of productivity across the oil and gas industry. All of these improvements will have the added benefit of reducing emissions.

These are just a few examples of what we are working on as we use our expertise and commitment to help lead the transition to low carbon solutions.