Deepwater managed pressure cementing: Breaking paradigms in the Gulf of Mexico

Cementing hydraulics is generally more complex than the hydraulics observed during the drilling phase. For instance, cement slurry and spacers high densities, thick rheological properties and narrower annular spaces commonly lead to high equivalent circulating densities (ECD) during cement placement operations. This condition, combined with mud weights (MW) designed to be above pore pressures, typically results in downhole pressures that approach or exceed open hole integrity limits. This is especially critical in applications in which there is a narrow pressure window between the pore and fracture profiles. Commonly, operators implement strategies to attempt mitigation of undesired results and non-productive time (NPT) during the cementing phase; however, in most cases, the root cause of the problem, which is the high ECD level obtained, cannot be addressed adequately by taking a conventional approach.

Achieving an effective zonal isolation behind the casing or liner wall is intimately related to preventing losses toward the formation, as well as flow from it during, and after, the cement circulation. When cementing a casing or liner string within limited open-hole pressure margins, maintaining the bottomhole circulating pressure (BHCP) below the fracture gradient is not feasible in most cases when using conventional methods.

MPD FOR DEEPWATER CEMENTING

The ability to control the well pressure profile with precision provided by modern managed pressure drilling (MPD) systems, has emerged in recent years as an alternative to solving the problem of cementing efficiently within tight margins in deepwater wells. The evolution of hydraulic modeling software, capable of accurately predicting fluid properties downhole, under dynamic and static conditions, combined with the latest MPD systems, is enabling drilling engineers to manipulate variables that were, in the past, out of reach during the drilling and cementing job planning.

Since 2018, several deepwater wells in the Gulf of Mexico (GOM) have demonstrated the advantages of the MPD technology in challenging offshore environments. On two of these wells, all riser sections were drilled, cased and cemented, using statically underbalanced mud weights, combined with the application of surface backpressure (SBP) control to maintain annular pressures within the available operating window, which at some depths was as narrow as 0.3 lb/gal equivalent. There was zero nonproductive time related to mud losses or well control recorded, and major capex savings were achieved by the operator as compared to past conventional drilling operations in the area, in similar wells.

WELL CONSTRUCTION/LOGISTICS

The biggest construction challenge for these wells was cementing successfully within such narrow windows, due to the high ECD to be obtained. Given the limited margins verified by the operators while drilling, conventional cementing for the lower strings was unfeasible without expecting severe losses. To solve the ECD issue during cementing, by means of a structured engineering process conducted by Weatherford, pump schedules were created, complemented with Surface Backpressure (SBP), to permit the use of Statically Underbalanced Mud Weights (SUBMW), with the objective of maintaining annular pressures within the available margins throughout the cement job.

The mobile offshore drilling unit (MODU) used by these operators to drill the wells was a “ship-shaped drilling unit,” with DNV 1A1 classification and described as a “DSME 12000 Ultra Deepwater Drillship.” The rotating control device (RCD) used for this application was a Weatherford below tension ring (BTR) type, complemented with an applied back pressure (ABP) MPD system at surface, which included a PLC controlled automated drilling choke.

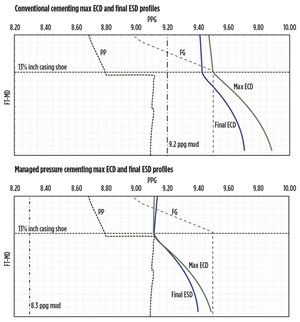

The main limitation for conventional cementing within a limited margin is the fact that the fluid properties and annular space configurations lead to peak ECDs (Fig. 1) and final EMWs columns that exceed the fracture limit at the final stages of the cement job. The peak or max ECD is reached at the instant prior to shutting down the cement pump. At that moment, the spacer and slurry volumes are contributing at their maximum effect on the bottomhole hydrostatic pressure, as well as to the annular frictional pressure loss in the annular space.

To address the issue using the MPD methodology, the BHP plan for the cement job is based on the analysis, modeling and manipulation of all the variables affecting annular pressure profile and bottomhole pressures during the cement job. The objective of the MPC calculation during the planning phase is to find the right set of conditions, and the required SBP levels, that will lead to annular pressures within the available operational window throughout the entire cementing operation.

ENGINEERING PROCESS

The engineering process that was implemented to plan the MPC operations on these wells consisted of three main stages: data collection, MPC engineering and program elaboration. Data collection could be one of the most important stages of the engineering planning of any well operation. Some of the most relevant information utilized to plan the operation included pore pressure; wellbore stability and fracture profiles; geothermal profile; well survey; mechanical configuration details; and mud properties. In addition, accurate information from the pumping services company was crucial regarding the cement properties, volumes, intended densities and pumping conditions, based on their experience to obtain proper isolation. The data collection also includes the inputs from the operator regarding the goals and targets to be accomplished during the job.

During the MPC engineering process, the gathered information is used to calculate and predict the annular temperatures and pressures to be obtained during the cement job. Besides evaluating variations of the circulating conditions and surface pressure, additional variables can be manipulated to evaluate the effect of the adjustment on the resultant pressure profiles. Fluid densities, viscosities, volumes and any fluid property, can be adjusted, as operationally practical, to find a set of conditions that, complemented with the application of surface backpressure, will enable the annular pressure profile to fit within the available margin throughout the entire operation.

RESULTS

The last step of the implemented MPC engineering process included the MPC program creation and disclosure, Fig. 2. Once all calculations were done, it was considered of paramount importance to communicate the results, instructions and suggestions in a clear way to all personnel involved in the cement job. The SBP plan and actions needed to be communicated clearly to the MPD crew on site, to facilitate a smooth execution and prevent any confusion or misunderstandings. The cement representatives, site supervisors and operator’s engineers and supervisors, who were making the operational decisions, needed to have a clear understanding of the calculations performed and the inputs used, as well as the pressures, flowrates and sequence of actions to be conducted during the cement jobs.

The result of the cementing operations conducted, demonstrated the benefits of Managed Pressure Cementing in tight operational drilling windows. A structured engineering process, combined with efficient execution utilizing a Weatherford MPD closed-loop system, aided these GOM operators in achieving the well objectives from the well construction perspective, in a much more economical, efficient and safe manner.

- Coiled tubing drilling’s role in the energy transition (March 2024)

- Advancing offshore decarbonization through electrification of FPSOs (March 2024)

- What's new in production (February 2024)

- Subsea technology- Corrosion monitoring: From failure to success (February 2024)

- Digital tool kit enhances real-time decision-making to improve drilling efficiency and performance (February 2024)

- E&P outside the U.S. maintains a disciplined pace (February 2024)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)