Executive viewpoint

I view the commercialization process from a very technical perspective, but I’ve had many discussions with non-technical people on the process that we follow, and thus have formed a few ideas on how we can improve it. While I am not an expert in procurement, I have been engaged in this for 35+ years, and it seems that we need a more streamlined approach, and not just be satisfied with the status quo.

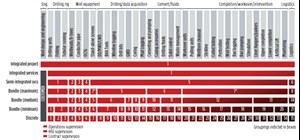

In many cases, we’ve already seen good changes adopted. From digitalization to reducing the numbers of people on rigs, we’ve made progress. But how many times have we seen a true, industry-wide focus on reducing waste—day in and day out? The time and effort we expend fulfilling requests for proposals and tenders is huge, and implementing continuous improvement methodologies could surely reduce waste in the process. The chart on this page shows how a typical services award is tendered, including the lengthy, arduous process that commercialization efforts take.

A typical process. One example of a recent tender with a major entity is a two-stage approach that was used. In the first stage, more than 10 tenders were organized for discrete services over a four-month period. This was followed by a technical and commercial evaluation over another four months, to pare down to a shortlist of successful bidders for the next stage.

Successful bidders were invited to submit a single commercial offer for all services combined. Evaluation took about eight to 10 weeks. That resulted in more than a year for the tender process. How many people-hours were spent on this—not only from the customer standpoint but from vendors engaged in the work?

The drawback was “tender fatigue” on all sides, resulting from excessive wasted time and resources. Realistically, tender time could have been streamlined to three months, had the customer used a single-stage process to combine all services.

It is staggering to think that operators might issue three dozen documents to an array of companies to fulfill a single job request. The number of people involved in creating and verifying materials, and meeting to discuss proposals, is a huge commitment, as are the time and effort taken by management to approve proposals.

A different way. Would it not make sense to integrate and streamline the process? As the chart shows, bundling could lower the number of documents from 35 to 21 for one integrated project. Our industry tends to want to drive a continuous improvement culture. When we look at this, are we really focused on even the very basic tasks of picking vendors to do work?

I am sometimes told that “we are already doing that.” But are we really? We now tend to issue discrete tenders and require alternative proposals, which only adds more time and effort to the process.And, I have been told by operators that some proposals they receive are trashed without even the courtesy of a review.

That doesn’t make sense for anyone, and in this age of digitalization and collaboration, why can’t we as an industry take the time to fix this? I challenge customers and service companies to find a better way to collaborate for continuing improvement of tendering, especially at a time when our industry is coming out of a downturn, and fewer dollars and people are available.

Smarter, integrated tenders are a better way. One method to ensure improvements in the process would be to make drilling rig operators, service providers, and customers all come together in one room to jointly deliver on projects. While this may not always be required, a joint approach among all parties would put everyone on a better footing while lowering costs, aligning safety, and achieving results faster. Could we take on projects in a “one coverall” approach? Think of the value gain that the industry might have, if we had three companies in the planning phase, in design, and searching out ways to optimize projects.

This may require thinking disruptively. It also challenges established processes. Of course, we would have to safeguard against possible corruption, but if we all worked together, we could take an enormous amount of waste out of the process and develop hydrocarbons more effectively. This may require looking at ways other industries handle their processes, but it’s a challenge we need to address head-on. Why not start today? ![]()

- Coiled tubing drilling’s role in the energy transition (March 2024)

- Advancing offshore decarbonization through electrification of FPSOs (March 2024)

- Shale technology: Bayesian variable pressure decline-curve analysis for shale gas wells (March 2024)

- What's new in production (February 2024)

- Subsea technology- Corrosion monitoring: From failure to success (February 2024)

- Using data to create new completion efficiencies (February 2024)