Collaboration delivers LWD triple-combo breakthrough for ultra-high-temperature wells

The oil and gas industry has amassed an impressive track record for developing new downhole tools and technologies to reach and recover hydrocarbon reserves in challenging environments. However, as the industry’s search for hydrocarbons takes it to deeper, hotter and more remote offshore basins, today’s downhole drilling and logging tools may reach their operational limits.

One of the most demanding proving grounds for downhole tools is the Gulf of Thailand. Many productive horizons in the Gulf of Thailand have bottomhole temperatures of up to 392°F, or temperature gradients of 3.2°/100 ft. HP gas reserves are found as deep as 11,000 ft, TVD; wells tapped into these deep reserves typically produce at high initial rates early on, but they quickly fall off as reservoir pressure is depleted.

With the goal of maximizing production at minimal development cost and risk in deeper basins, operators rely on continued advances in measurement-while-drilling (MWD) and logging-while-drilling (LWD) tools. These tools deliver the real-time data necessary to increase ROP, minimize NPT, provide accurate reservoir evaluation, and ensure effective well placement.

Until recently, however, the vast majority of so-called high-temperature LWD tools had an upper temperature operating limit of 347°F. This limitation often forces operators working in basins above this temperature to consider alternative drilling methods, none of which are ideal. For instance, operators may forego the use of MWD and LWD tools in ultra-high-temperature sections of the well and rely only on extrapolations from recent directional surveys to continue drilling, which is equivalent to drilling blindly. A more commonly used practice for temperature mitigation is to partially or completely pull the drillstring out of hole multiple times during a run, to allow the bottomhole assembly (BHA) and LWD tools to cool down before redeploying. Or, in situations where the current well being drilled might converge with a nearby existing well, they may have no choice but to simply stop drilling before reaching the target depth (TD) and accept less-than-optimal well production rates.

COLLABORATIVE BREAKTHROUGH

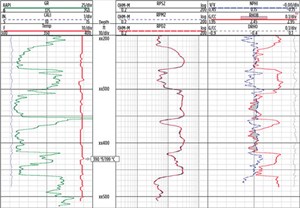

In 2014, Chevron Thailand and Weatherford aimed to overcome these challenges through a collaborative effort that would develop a robust, enhanced LWD toolstring, capable of providing real-time downhole data while withstanding temperatures of up to 410°F. After nine months of research and field tests, the companies successfully delivered the Phase 1 HeatWave Extreme (HEX) service. The HeatWave Extreme service includes a HPHT-rated tool equipped with directional sensors and mud-pulse telemetry, in addition to gamma ray, bore and annular pressure (BAP) sensors, and a thermal neutron porosity sensor, Fig. 1.

During its first field deployments, the HEX service helped reduce the number of temperature mitigation trips out of the hole. Additionally, it enabled the operator to drill to planned TDs without having to stop short and lose valuable pay, due to collision uncertainty or lack of real-time petrophysical data. In 2015, Phase 1 HEX technology drilled 30 wells in a combined 1,413 operating hours, including a total of 532 operating hours where temperatures exceeded 347°F. Drilling operations were completed with less than 1% NPT.

ACHIEVING TRIPLE-COMBO CAPABILITY

Following the successful deployment of the Phase 1 HEX service, which was recognized as an innovative high-temperature technology by the SPE Thailand E&P Annual Awards Program, Chevron and Weatherford turned their attention to expanding the measurement potential, to incorporate the full suite of triple-combo LWD measurements.

The Phase 2 technology includes all of the measurements of the Phase 1 system, with the addition of resistivity and formation density measurements. The service was designed to deliver the same measurement quality obtained with conventional triple-combo LWD tools, but at temperatures up to 392°F.

As part of the development, Weatherford designed new electronics and sensor packages for each LWD tool, Fig. 2. The company also partnered with component die manufacturers, ceramic packaging vendors and hybrid assembly shops, to develop new internal circuitry that could withstand the high-temperature downhole environment. Tight space constraints within the printed circuit boards required circuit functions to be combined into ceramic multi-chip modules. Due to the absence of viable silicon, new circuits were designed from first principles using alternate components to achieve the same functionality.

The new packages underwent a series of qualification tests prior to testing in the field. The tools were tested for operation at 392°F for 250 hr, with excursions to 14°F and 410°F to simulate rapid transients when tripping from hot reservoirs to cold deck-checks on surface. Lastly, the electronics packages were subjected to random frequency-vibration testing at 10-to-15-g accelerations, at a temperature of 392°F.

To assure reliable tool performance in the field over time, Weatherford developed a comprehensive, performance preventative maintenance program, including a mechanism to track the time at which a given tool is exposed to various temperature and vibration levels, and adjust maintenance schedules for each sensor component accordingly.

SENSOR SPECIFICS

Measuring the bore and annular pressure with the BAP sensor aids the drilling dynamics analysis and safe drilling practices. Accurate and reliable bore and annular pressure measurements are provided by two separate, temperature-compensated Quartzdyne pressure transducers. When drilling at high ROPs, such as those seen in the Gulf of Thailand, monitoring the measured equivalent circulating density (ECD) and differential pressure is critical to verifying hole cleaning and avoiding pack-off.

An accurate, natural gamma ray measurement at high temperatures is achieved by employing an insert-based detector. This detector is composed of multiple banks of Geiger Muller tubes, which have been used for decades in the industry and are known for providing stable measurements at high temperatures while withstanding high levels of shock and vibration. The benefit of an insert-based detector is that it allows for multiple placement options within a BHA.

The resistivity component of the HEX triple-combo service is provided by an HPHT-rated, multi-frequency resistivity (MFR) tool. The HEX MFR propagation resistivity sensor operates at 2 MHz and 400 kHz, with three spaced transmitters that provide 12 individual compensated curves with variable depths of investigation and vertical resolutions. Real-time curve selection is customized to accommodate the application, whether the objective is calculating water saturation, geosteering, or both.

The HEX high-temperature neutron porosity measurement is captured, using existing, proven Helium-3 detector tubes with upgraded high-temperature electronic processors and downhole memory. LWD neutron porosity measurement is particularly valuable in Gulf of Thailand operations for identifying gas-bearing formations, particularly when combined with the HEX formation density measurement.

Recognized by the industry as the most reliable porosity measurement, formation density was a necessary addition to the HEX service. In addition to

providing the formation density (RHOB) measurement, the HEX density sensor uses two scintillation detectors to provide density correction (DRHO) and a borehole caliper to measure wellbore shape and size. As scintillation detectors are susceptible to thermal degradation, the thermal exposure history of each detector is tracked through the preventative maintenance program, and detector packages are replaced before significant deterioration in signal quality can occur.

MAKING AN IMPACT

From its first runs during second-half 2016, the LWD triple-combo service quickly made a significant impact in optimizing drilling operations. Chevron’s drilling program in Gulf of Thailand wells calls for drilling with a balance between ROP and directional control, and specifies that each section be drilled using one bit per section, for a total of three bits needed to reach TD. Mud motors are typically used in the surface and intermediate sections, and a single rotary-adjustable gauge stabilizer (AGS) assembly is deployed in the production section.

Chevron relies heavily on data analysis to improve its drilling performance. This is especially true when selecting bits and designing the AGS and supporting stabilizers to help maintain its three-bit-per-well goal in ultra-high-temperature formations. By pairing the Weatherford StableLine AGS (which is rated to 428°F) with the Phase 2 triple-combo service, single sections are drilled consistently to lengths of 9,000 ft, which is 1,000 ft greater than Chevron’s standard operating protocol for drilling the production section of a well.

This pairing of the AGS and the HEX service routinely affords a single-bit trip to TD in the production zone. Prior to the development of the HEX service, drilling dual-bit runs—a first run with a standard tool and a second run with a “dumb iron” assembly or high-temperature tools—was typically required. Deploying the HEX service, and eliminating the second run, saves 12 to 15 hr of bit-trip time per well to change out the BHA.

The LWD triple-combo service also eliminates the need for a dedicated wireline triple-combo run. This not only saves several hours of running time per well, but it also reduces radioactive material handling and eliminates the risk of getting the wireline assembly stuck downhole with the radioactive source.

At the time of this writing, the HEX triple-combo service has been used to drill 45 wells, with an average downhole temperature of 369°F and a total length of 296,000 ft. Of its combined 3,500 operating hr, nearly one-third of this time (1,100 hr) was spent at temperatures above 347°F. The maximum circulating temperature while drilling was 390°F, while the maximum recorded static temperature was 396°F—both achieved without tool failure.

The tools registered only 40 hr of NPT, representing just 1.1% of total operational time during these runs. On average, the triple-combo service has reduced drilling time 28% per well while delivering reliable, real-time data at 392°F.

The new service recently helped Chevron Thailand set two drilling records in one well. The PAWQ-29 well was drilled to a TD of 17,559 ft in just 7.42 days, making it the longest well that the operator had drilled in the region. In addition, the service helped the operator to achieve the longest one-bit run in the production section, with a length of 8,952 ft. The HEX service successfully drilled all sections as planned, and withstood static temperatures of 420°F and a maximum circulating temperature of 390°F, Fig. 3.

PROVING ITS WORTH

In the span of just two years, the HEX service has proven its ability to provide recorded and real-time downhole data-while-drilling in the hostile environments of the Gulf of Thailand. With the addition of true triple-combo measurements, the service has further increased the reliability of data delivery and reduced drilling time, while allowing Chevron Thailand to mitigate their operational and economic risks during HPHT drilling operations.

Weatherford is currently investigating further applications for the ultra-high-temperature LWD triple-combo service in both new and mature high-temperature fields, where it has the potential to save millions of dollars in capex well costs. In new fields, the robust service’s ability to run for longer times at higher temperatures means that wells can be drilled farther, to explore deeper pay potential without the time and expense of tripping-out to switch to an HPHT BHA.

The service also opens up the possibility of extending the productive life of existing assets through enhanced hydrocarbon recovery. Reserves previously considered uneconomical, due to their depth and ambient temperatures and pressures, can now be drilled and evaluated more cost-effectively, and brought to the surface using existing production infrastructure for minimal added capex. In addition, wellhead platforms that stopped producing, or have simply been abandoned, due to declining production rates, can now be revitalized by using the new service to explore untapped deep-pay potential.

The value of this collaborative development extends far beyond cost and time-savings in the Gulf of Thailand. Plans are underway to deploy the full HEX suite in other deep HPHT basins, thus opening up the full production potential of complex assets around the world. ![]()

- Coiled tubing drilling’s role in the energy transition (March 2024)

- Advancing offshore decarbonization through electrification of FPSOs (March 2024)

- The reserves replacement dilemma: Can intelligent digital technologies fill the supply gap? (March 2024)

- Subsea technology- Corrosion monitoring: From failure to success (February 2024)

- Digital tool kit enhances real-time decision-making to improve drilling efficiency and performance (February 2024)

- E&P outside the U.S. maintains a disciplined pace (February 2024)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)