2017 <i>World Oil</i> Awards

More than 300 of the upstream oil and gas industry’s brightest minds gathered to find out, and celebrate, the winners of the 2017 World Oil Awards on Oct. 12. The awards ceremony, now in its 16th year, seeks to recognize and honor the upstream industry’s top innovations and innovators.

Honorees took home awards in 18 categories—encompassing the full breadth of the upstream industry—from the gala event at the Houstonian Hotel in Houston, Texas. Today’s innovations, many of which would have seemed far-fetched a generation ago, are enabling operators to find and produce hydrocarbons more safely, economically and efficiently.

This year, 240 nominations were submitted from more than 22 countries around the world. Ninety-eight finalists were selected, and the award winners on the following pages were hand-picked by the World Oil Awards advisory board as this year’s most groundbreaking industry developments.

As part of World Oil’s commitment to the industry’s long-term health, each year the World Oil Awards endow a leading university, which provides education for careers in the petroleum industry, with much-needed funding to equip the next generation of innovators. Since the inception of the World Oil Awards, donations have been distributed to 33 universities and organizations as varying as the University of Houston and the University of Ibadan in Nigeria. However, this year’s beneficiary is Oilfield Helping Hands, a nonprofit charitable organization that helps oilfield families with financial assistance in times of crisis. This donation was made in light of the vast flooding that occurred in Houston during late August, and which affected so many families in the industry.

The 2017 World Oil Awards were generously sponsored by: AFGlobal; Baker Hughes, a GE company; Clariant; Halliburton; and Eddie V’s Prime Seafood. On behalf of the World Oil Awards advisory board members, Gulf Publishing Company and World Oil, congratulations to this year’s winners and finalists. Your commitment to revolutionizing the industry with cutting-edge technology and innovative ideas will continue to inspire your peers and the next generation of leaders.

Best Completion Technology

This award recognizes the leading solution that provided a substantial impact on the industry’s completions. Criteria for the award include innovation, reliability, commercial application and industry impact.

Finalists: Bullmastiff Openhole Sand Control Ball-Drop Fracturing System, National Oilwell Varco; Cemented QuickPORT IV Sleeves, Packers Plus Energy Services, Inc.; Electric Hydraulic Fracturing Equipment, Evolution Well Services, LLC; Propel SSP & Propel SSP 350, Fairmount Santrol; Remote Fluid Grip Tong, Frank’s International; StackFRAC HD-X, Packers Plus Energy Services, Inc.; Torrential High Flow Filtration Unit, M-I SWACO, a Schlumberger Company

Winner: MZ-Xpress Single-Trip Multizone Frac- and Gravel-Pack System, Schlumberger

Operators want to improve efficiency of sand control operations while increasing production in depleted, unconsolidated and laminated formations. The MZ-Xpress completion system performs multi-zone gravel and frac packing in a single trip. All zones are perforated, and then system hardware is deployed, set and tested. Individual zones are gravel- or frac-packed from the bottom up. The system allows complete isolation of zones not being completed immediately, and can be used when interval lengths or zone spacings differ. It addresses from two to more than five zones, and is suitable for low-tier and land wells, as well as the next generation of challenging deepwater wells. By eliminating trips, the system saves time and improves field economics, particularly for subsea wells.

Best Data Management & Application Solution

This award is given for an implemented, viable workflow solution, focused on data storage, delivery or management processes and technologies, that provided tangible results for an operator or service company.

Finalists: Kinetix Shale Reservoir-Centric Simulation-to-Production Software, Schlumberger; Lift IQ Production Life Cycle Management Service, Schlumberger; Rigsentry BOP Monitoring, National Oilwell Varco; RS Prism, RS Energy Group; Siemens Condition Monitoring (CM) for the Ivar Aasen Field Development Project, Siemens; VERITRAX: A Revolution in Chemical Management Through Adaptive Digitization, Clariant; ZAIMS (Zentech’s Asset Integrity Management Solution), Zentech, Inc.

Winner:proNova, TDE Petroleum Data Solutions

The first of its kind, proNova is a rigorous, data quality control service that enables operators to monitor and organize global rig operations accurately and efficiently. The service uses rig sensor data to automatically generate an objective description of the well construction process, using a patented, Automated Operations Recognition System, without the need for additional rig site personnel. It analyzes rig operations at a high level of quality and detail that complements traditional morning reporting. The system significantly reduces well construction time by setting standardized, objective benchmarks, to identify Invisible Lost Time (ILT) and Lost Time (LT), while maintaining increased performance.

Best Deepwater Technology

This award recognizes significant technology in the area of drilling, completions and production in deepwater applications.

Finalists: BigBore IIe Subsea Wellhead System, Dril-Quip, Inc.; DEEPFRAC Deepwater Multistage Fracturing Service, Baker Hughes, a GE company; Liquid Mud Plant vessel (LMPV), Zentech, Inc.; OneTrip BOP Testing Tool, Samoco Oil Tools; TechnipFMC’s 15K 400F HPHT Subsea Production System, TechnipFMC; Safe-Stor Chemical Storage, Safe Marine Transfer, LLC; WellWatcher Flux Multizonal Reservoir Monitoring System, Schlumberger

Winner: Managed Pressure Drilling Integrated Solution, Schlumberger

Operators conducting a managed pressure drilling (MPD) operation no longer need to rely on coordination of multiple entities throughout the phases of installation, commissioning and execution. An industry first, the MPD integrated solution is a complete, all-OEM, reservoir-to-flare-stack deepwater MPD system. It provides design, engineering, manufacturing, system integration, well engineering and onsite well delivery services, from one platform and from a single supplier. It allows operators to reduce the product, controls system, and human-machine interface footprint, while providing the flexibility to switch between MPD applications and riser gas handling operations. Overall, the solution offers real-time operational adaptability, less downtime and associated rig costs, as well as improved use of offshore rig space.

Best Drilling & Completion Fluids

This award recognizes an innovative drilling or completion fluid, or a fluid-related mechanism or process, that was introduced commercially within the last year, and which helped to drill for, or produce, oil or gas.

Finalist:ClearPAC HT High-Temperature Polymer-Free Gravel-Pack Fluid, Schlumberger

Winners: (TIE) Halliburton Baroid BaraECD High-Performance Invert Emulsion Fluid System, Halliburton; PrimoPAC: The Stable, Reusable Solution for Optimal Openhole Gravel Pack Integrity, M-I SWACO, a Schlumberger Company

Halliburton’s BaraECD is a high-performance Invert Emulsion Fluid (IEF) system that has been engineered for narrow pressure-margin applications, where Emulsion Circulating Density (ECD) is often a limiter. The fluid’s components provide a unique rheology structure that delivers optimum suspension characteristics. It incorporates a set of surfactants, colloidal solids and new proprietary polymers that results in unrivalled weight stability and minimal ECD behavior. Because the system is flexible, it also can accommodate varying sizes of weighting agents. The fluid system is designed to optimize drilling performance, improve safety, and increase access to reserves.

Schlumberger’s PrimoPAC fluid is an invert emulsion gravel pack carrier fluid, used for alpha/beta openhole gravel packing completion challenges, when wells are drilled with synthetic or oil-base reservoir drill-in fluid. With a simple fluid chemistry—merely base oil, brine and emulsifier—the fluid allows operators to drill and complete in all oil environments, improving the efficiency of operations, as well as optimizing displacement, eliminating compatibility issues, and minimizing risk of failure. It also is reusable, and can be recycled with drilling fluids, further reducing costs related to disposal.

Best Drilling Technology

This award goes to innovators, who executed an industry-leading effort during the year that had significant impact on the industry, onshore or offshore, through drilling innovation.

Finalists: AxeBlade Ridged Diamond Element Bit, Smith Bits, a Schlumberger Company; HeatWave Extreme Service, Weatherford International; IQ Monitoring System, National Oilwell Varco; NOV Vector Series 50 Drilling Motor, National Oilwell Varco; Radian Azimuthal Gamma and Inclination Service, Halliburton; RheGuard Micronized Barite Non-Aqueous Drilling Fluid, M-I SWACO, a Schlumberger Company

Winner: SpectraSphere Fluid Mapping-While-Drilling Service, Schlumberger

Operators strive to fully understand reservoir fluid properties during drilling operations to create new possibilities in well placement and reservoir characterization. The SpectraSphere fluid mapping-while-drilling service maps reservoir fluids in real time and in multiple environments, enabling advanced knowledge of untapped reservoirs during exploration. It also mitigates risk while performing fluid analysis and sampling in highly deviated development wells. The service provides everything from accurate pressure measurements to downhole fluid analysis and high-quality samples while drilling. It allows operators to fully understand reservoir fluid properties and their variations during drilling operations, which enhances well placement and reservoir knowledge considerably while reducing costs.

Best EOR Technology

This award is given to a company whose innovative EOR technology has enhanced crude recovery substantially.

Finalists: MYCELX RE-GEN Advanced Water Treatment Media, Schlumberger; RELTREAT, Clariant

Winner: Ultra-Low Surfactant Retention (LSR) Flooding in Carbonate Reservoirs, Ultimate EOR Services

Oil recovery from tight, oil-wet carbonate reservoirs is often poor due to heterogeneity and high residual oil saturation. EOR methods such as gas flooding often suffer from gravity override or lack of viable injectant source, while surfactant flooding suffers from high retention of injected chemicals, challenges of managing high temperature and salinity, and poor transport of the injected fluids. The ultra-low surfactant retention (LSR) flooding is an approach that simultaneously addresses issues of retention and transport of surfactants and polymers. Dilute concentrations of high-performance surfactant are injected, with brine and polymer, for mobility control. The injection fluid, which contains a hybrid alkali, alters the surface mineral charge from positive to negative, decreasing absorption of chemicals, and improves transport in low-permeability rock. Ultimately, the process lowers chemical concentrations 85%, resulting in high recovery and low surfactant retention.

Best Exploration Technology

This award is given for the leading acquisition technology (including seismic, geochemistry and remote sensing) or algorithm/processing technology introduced during the previous year.

Finalists:Deep Shear Wave Imaging Processing Service (DSWI), Baker Hughes, a GE company; GeoTesting Geology-Based Well Test Design and Interpretation, Schlumberger; Indicator for Gas Sweet Spots, Saudi Aramco

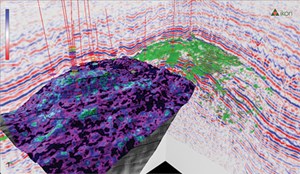

Winner: RokDoc Ji-Fi, Ikon Science

RokDoc Ji-Fi is an advanced Bayesian seismic inversion system that combines geological information with a dedicated rock physics relationship, for each of the rock types expected to directly predict rock properties of interest using seismic data. The system is essentially an algorithm used to deliver both rock type and rock-type consistent properties, while also handling seismic noise and geological uncertainties. Results provide better models of rock properties and rock types, minimizing subsurface risk and maximizing reward from accurately defined oil accumulations. It determines the location of various rock types, including oil-bearing sands.

Health, Safety, Environment/Sustainable Development—Offshore

This award is presented to a company that has made significant strides in protecting and enhancing the offshore environment where it operates. Whether through technical innovations, implementation of new standards or processes, or introduction of social and economic development efforts, the winner will have a program that made a marked improvement in an HSE/sustainable development endeavor.

Finalists: BridgeMaker Lost Circulation Material, Halliburton; EcoStar Electric Tubing-Retrievable Safety Valve, Halliburton;

Machine Control Diagnostic Tool (MCDT), National Oilwell Varco; National Energy Technology Laboratory Well-Bore Integrity Team (Foamed Cementing Technology), National Energy Technology Laboratory; RISE Workstation, National Oilwell Varco; SandStoneDivert Viscoelastic Surfactant Diverter System, Baker Hughes, a GE company

Winner: ATC VAC Automatic Tank Cleaning with Vacuum Truck, M-I SWACO, a Schlumberger Company

Using a vacuum system to clean pits aboard offshore rigs is time consuming and produces unnecessary amounts of waste. The ATC VAC is a mobile automatic tank cleaning system that was designed to eradicate confined space entry, minimize logistical cost creep and reduce environmental impact footprint in the offshore market. The system was integrated into a vacuum tanker, to save boat transit time that was lost during quayside turnaround with traditional tank-cleaning systems. It has been proven to reduce cleaning time by up to 60%. The system also has a patented mechanism that enables dead volume to be vacuumed from the tanks and ATC system, and then pumps wash water through automatic cleaning jets installed on the boat tank. It simultaneously recovers dirty wash water and recycles it for immediate use.

Health, Safety, Environment/Sustainable Development—Onshore

This award is presented to a company that has made significant strides in protecting and enhancing the onshore environment and communities where it operates. Whether through technical innovations, implementation of new standards and processes, or introduction of social and economic development efforts, the winner will have a program that made a marked improvement in an HSE/sustainable development endeavor.

Finalists:Constructed Wetland (REED BED): A Sustainable Solution, Vedanta Limited, Cairn Oil & Gas, Bhagyam Oil & Gas Mine; HOSTAFRAC: High-Performance Flowback Aids Base Upon Sustainable Sources of Sugar, Clariant Oil and Mining Services; The PowerCore Genset, Dynamo Micropower; Uthmaniyah CCS and CO2-EOR Project, Saudi Aramco

Winner: Sand X and Super Loop, Sand X

Operators required a method to close the loop on gases in the drill-out and well completions process. The Super Loop’s primary function involves a five-phase separation of gas, condensate, oil, water and solids during the drilling and completion phases of exploration and production. A mobile steel deck supports a self-erecting gas separator that is able to continuously flow and simultaneously separate natural gases from hydrocarbon liquids, water and sand. The Sand X is used as a primary recovery tank in drill-out and flow-back operations. Sand X is an environmentally-friendly, safe and cost-saving system for sand disposal in the completion process. This process allows reuse of water for drilling, which saves cost and is environmentally-friendly. It also eliminates hazardous waste exposure and disposal, and the need for confined space entry, which helps keep workers safe. Using green technology, the Sand X restores sand for use for other applications.

Best Outreach Program

This award spotlights a program that has done the best job of teaching the general community, and younger generation, about the value of the oil and gas industry, which is often one of the greatest challenges confronting the energy sector.

Finalist: STEPS, Halliburton

Winner: STEPS, Halliburton

The Science and Technology for Exploration and Production Solutions outreach program, called STEPS, enables graduate students to engage with the oil and gas industry through access to real-world datasets, including proprietary data, from Halliburton’s Landmark business. The program also gives students access to mentoring and training through face-to-face, e-learning and remote instruction by a dedicated team that forms the STEPS network. The projects are cloud-hosted, providing a secure, remote and collaborative working environment that anticipates future working practices. While STEPS projects are designed for students pursuing master’s degrees, a long-term goal is to include multi-year research projects that are available to doctoral and post-doctoral candidates. All STEPS participants will be eligible for the “New Geoscientist of the Year” award, which recognizes the best STEPS student thesis of the year. This recognition also offers future recruitment opportunities. The STEPS program fosters geoscience excellence, and it’s Distinguished Lecture Series provides opportunities to learn from renowned subject-matter experts. During the program’s first year, lectures were presented in the U.S., Europe, the Middle East and Southeast Asia.

Best Production Chemicals

This award is given to a company whose innovative stimulation or treatment chemicals have enhanced the production of oil and gas.

Finalists: Ascend Surfactant Solution, Multi-Chem, a Halliburton Service; SCAVINATOR: The Next Generation in Non-Triazine H2S Scavenging, Clariant Oil and Mining Services

Winner: Chemical Solutions for Near-Wellbore Damage, Baker Hughes, a GE company

Paraffin, asphaltenes, scale, and emulsion blocks in the near-wellbore area restrict flow from the formation, causing production challenges including unexpected decline curves, increased lifting costs, and lower performance in injection operations. However, new near-wellbore damage technologies have been proven to restore performance of the well, minimize soak time, and restore the wettability of the formation to its natural water-wet state, which improves hydrocarbon flowrates. This multi-functional chemical solution treats a number of issues in one application—saving time, reducing risks to employees and improving productivity.

Best Production Technology

This award recognizes a newly introduced production program, solution or fluid utilized during the year that allowed an operator to effectively manage and maximize production.

Finalists:AvantGuard Advanced Flowback Services, Schlumberger; Electric Submersible Twin Screw Pump (ESTSP), Dass Can-K Pumps Inc.; Mobile Offshore Production Storage and Offloading Unit (MOPSOU), CDC Scotland Ltd.; PCL Production Composite Log Service, Schlumberger; Silverwell’s Digital Intelligent Artificial Lift (DIAL), Silverwell; TransCoil Cable Deployed ESP System, Saudi Aramco and Baker Hughes, a GE company

Winner: Raptor 2.0 Cased Hole Evaluation System, Weatherford International

The Raptor 2.0 cased-hole reservoir evaluation system delivers definitive oil and gas saturation data, providing 250% more sensitivity than standard two-detector pulsed neutron tools. Rather than generalized interpretation of the reservoir, the system finds and defines bypassed oil and gas volumes to within a few saturation units. These logs provide a precise roadmap to quickly increasing production. It includes a first-of-its-kind five-detector array pulsed-neutron tool, advanced petrophysical workflows and a wide range of answer products, from standard fluid saturation to openhole replacement and specialty services. Every well logged by the new system is characterized individually using Monte Carlo modeling, which accounts for the combined effects of borehole size, casing, tubing wellbore and annular fluids, lithology, and reservoir fluids. This creates a clear oil and water response production. Once data reaches the surface, Weatherford petrophysicists use proprietary software to merge measured data in the response envelope.

Best Visualization and Collaboration

This award recognizes the data visualization, storage, software or manipulation solution that shows the greatest promise in enabling operators to achieve and create a real-time collaborative environment with potential for a step-change in operating efficiency.

Finalists: AccuView System, Weatherford International; ChemWatcher Integrated Chemical Management Software, M-I SWACO, a Schlumberger Company; DecisionSpace Augmented Reality and Virtual Reality, Halliburton; DISPLAY, Frank’s International; Oceaneering PortVision 360 Service and Asset Monitoring Intelligence Center (AMIC), Oceaneering International, Inc.

Winner: OptiWell Well Construction Performance Service, Schlumberger

The OptiWell well construction performance service monitors and analyzes surface and downhole conditions in real time, to improve the overall safety and efficiency of the well construction process. From 24/7 monitoring for downhole hazards, to identifying operational inefficiencies, the new service enables mitigation of HSE risks, and both invisible lost-time and nonproductive time. The performance management component of the service analyzes and benchmarks well construction operations, and compares them to key performance indicators. Based on these data, appropriate measures can be taken to increase well construction efficiency.

Best Well Integrity Technology

This award recognizes a company with technical, operational or organizational solutions, which reduce the risk of uncontrolled release of formation fluids and provide E&P operators with an increased level of well integrity assurance.

Finalists:Bore Erosion Measurement & Inspection System (BEMIS), LaserStream, LP; CemFIT Heal Flexible Self-Healing Cement System, Schlumberger; Electromagnetic Pipe Xaminer V and Acoustic Conformance Xaminer Services, Halliburton; LiquiLite Cement Additive, Halliburton; Saltel Expandable Steel Packers and Patches, Saltel Industries, a Schlumberger Company

Winner: Endura Dual-String Section Mill, Weatherford International

Thousands of wells await a safe P&A operation. With more wells reaching the end of their productive lives every year, the need for efficient and reliable P&A technologies is at an all-time high. Operators have two primary goals for P&A operations: to achieve a permanent barrier that halts hydrocarbon migration, and to reduce operating costs. The Endura daul-string section mill addresses these priorities. The new tool creates a stable, permanent, and verifiable rock-to-rock barrier for plug-and-abandonment operations. The tool produces the ideal cement-to-formation bond and does so in half the time of conventional plug-and-abandonment techniques. Rather than removing thousands of feet of dual-string casing, the mill takes a surgical approach by milling through select 100-ft long sections of casing strings. The new tool also features separate stabilizers and specially-designed 4.5-to-13-in.-long carbide cutting structures that enable through-casing milling of the adjacent casing string.

Best Well Intervention

This award is for advances in well maintenance, which can represent the highest expenditure over the life of a well. This award recognizes new intervention technologies that help make significant improvements in terms of time saved, costs reduced or production improved.

Finalists:Global Rapid Intervention Package, Halliburton; HZT Workstring Tubing Connection, Certus Energy Solutions; MASTODON Hydraulic Pulling Tool, Baker Hughes, a GE company; Pressure Deployment CT System, Schlumberger; SPECTRUM FUSION, Halliburton

Winner: Blue Ocean Riserless Intervention System (BORIS), Oceaneering International, Inc.

The Blue Ocean riserless intervention system, called BORIS, is a wireline-based solution for subsea downhole intervention; well stimulation and remediation; and plugging and abandonment. It is ROV-compatible and can be deployed from dynamically-positioned multi-purpose vessels or mobile offshore drilling units. The system functions to water depths of 10,000 ft and pressures as high as 10,000 psi. It comprises two connectable sections—upper and lower well control modules—and can be field-configured to run slickline or e-line, depending on well conditions and operator need. The modules contain the main umbilical interface, a proprietary wireline grease system, a subsea pressure control head, and a contingency wireline BOP. A lubricator assembly houses the relevant well intervention toolstrings, subsea pressure control head, and subsea packoffs. The system’s diverse functionality is enabled by its interchangeable wireline toolstring, which is changed by unlatching the lubricator assembly from the upper well control module and recovering it to surface.

Innovative Thinker

This award honors an individual, who has demonstrated thought and leadership in the upstream oil and gas sector. The winner is an inspiration to all and a champion of the industry, not only in terms of the breadth of achievements, but also through the demonstration of vision and innovative thinking.

Finalists: Dr. Meenakshi Bhattacharjee, Rice University; David Cam, Hydrus Technology; Rocco DiFoggio, Baker Hughes, a GE company; Dr. S. Rao Guntur, Zentech, Inc.

Winner: Dan Scott, Baker Hughes, a GE company

Dan Scott is one of the most prolific inventors in the history of Baker Hughes, a GE company. Through his nearly 50-year career, Mr. Scott has garnered 138 patents, and has helped guide BHGE through various mergers and transitions while developing transformative products and services for the oil and gas industry. He has authored more than 60 publications and is a fellow in ASM, and has won a Silver Patent Award from ASME. Dan has also received a Distinguished Member Award from SPE, a Lifetime Technology Achievement Award from Baker Hughes, and an IADC Exemplary Service Award. Some of the technologies that he has contributed to include hard-facing, steel-tooth and carbide-insert bit designs; PDC cutters and PDC bit designs; improved diamond-impregnated carbide bits and components; nano-materials, instrumented cutters and sensors for drilling tools. In fact, Mr. Scott worked on, and developed, the first PDC bit product line out of synthetic diamond material at BHGE, which earned him the nickname he carries today: Diamond Dan.

Lifetime Achievement

This award honors an individual, who has made significant strides, and impacted the oil and gas industry, throughout his or her career. The recipient may be retired from the industry, but will be an individual whose legacy still has an impact. Nominee must be living.

Finalists: Saad M. Aldriweesh; David Curry; Dr. Nihal Obeyesekere

Winner: Rustom Mody

As vice president of technology for multiple product lines, Rustom Mody is an integral part of Baker Hughes, a GE company (BHGE) and the energy industry. As a teacher, innovator and mentor, Mr. Mody cultivated a culture founded on entrepreneurship and scientific inquiry that has led to significant industry breakthroughs. He has 18 patents to his name, has written more than 75 papers and technical articles, and has participated in numerous conferences by presenting keynote addresses. The nanotechnology and advanced materials program that he oversees developed controlled electrolytic materials surfactants for enhanced oil recovery and fiber optics for intelligent production systems. Rustom has built strong relationships with key industry technology organizations, forums and thought leaders to remain current on leading industry technology trends and developments as they apply to BHGE strategy and direction. He also has been appointed to serve on the advisory board of Council on Competitiveness Technology Leadership and Strategy Initiative with the Department of Energy’s Material Genome Initiative.

New Horizons Idea

The winner of this award is a company with a game-changing product, technology or idea that redefines the industry’s thinking. The winner of this award symbolizes how the industry will operate in the future and will serve as a guidepost to the next generation of leadership entering today’s upstream energy sector.

Finalists:Exploration Insights PlayFinder Software, Halliburton; LateralScience Engineered Completions Process, C&J Energy Services; Motive Bit Guidance System, Motive Drilling Technologies; Pulsar Multifunction Spectroscopy Service, Schlumberger; Rock-on-a-Chip Microfluidic Device, Multi-Chem, a Halliburton Service

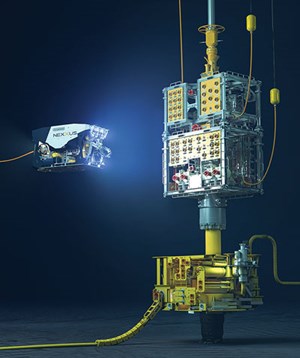

Winner: E-ROV Concept, Oceaneering International, Inc.

Oceaneering International is working with Statoil to develop, manufacture, test and mobilize a self-contained, battery-powered, remotely-operated vehicle system that is deployed on the seabed. The system, called an E-ROV, will interface with the company’s Mission Support Center via a 4G mobile broadband signal, transmitted from a buoy on the water’s surface, without a surface vessel required onsite. The system includes a subsea garage, eNovus ROV, and an advanced communication system that can operate on a 4G network. The subsea garage includes a cage-mounted 100-kW batter pack and a tether management system. The eNovus is modified to include advanced battery technologies and optimized to handle peak power consumption and to support operations. Continuous vessel support is eliminated with a remotely operated system that resides on the seafloor. ![]()