New workstring connection improves tubular performance, economics in horizontal wells

The recent shale revolution has prompted technological advancements in every phase of the well life cycle. Producers and service providers are striving continually to cultivate equipment and techniques to streamline horizontal well development. These efforts have yielded significant progress in the ability to economically drill and complete horizontal wells. While service equipment has continued to evolve in that pursuit, those few technologies that have yet to progress are proving to be an economic burden in an already distressed climate.

One unchanged oil country tubular goods (OCTG) commodity that is gaining such notoriety is workstring tubulars. For more than a half-century, E&P companies have relied on the integral upset two-step, or PH-6, connection for their well intervention requirements. However, the very design elements, which have cemented the two-step connection as the preferred workstring for decades, are proving problematic in the era of horizontal drilling.

Horizontal well intervention dynamics pose unique operational and economic challenges to the workstring industry. With PH-6 tubing, these dynamics promote excessive tool joint wear, which ultimately leads to premature tubing downgrades. Tubing downgrade replacement costs are not a new phenomenon in the rental industry; however, the recent surge in premature downgrades is forcing producers to incur disproportionate and unanticipated replacement tubing charges at a time of increasing capital restraints. This unprecedented asset turnover is likewise hampering the profitability of rental tubing providers, as companies are unable to recoup the cost of their investments. Attempts have been made to minimize the impact of tool joint damage, but the underlying issue remains; the two-step connection simply wasn’t designed with horizontal wellbores in mind.

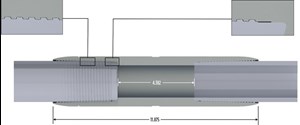

With the patented technology of the HZT (Horizontal Tubing) connection, Certus Energy Solutions has developed the first high-performance tubing connection tailored to horizontal well interventions, Fig. 1. In doing so, the company has designed a tool joint that not only alleviates premature downgrade concerns, but also reduces connection damages, eliminates re-cut limitations, and provides the superior mechanical properties demanded of extended lateral operations.

AN INDUSTRY EPIDEMIC

The two-step connection has long been the cornerstone of tubular well interventions, due to its effective integral upset design. Minimal engagement between the tool joint upset and casing wall during vertical well operations encouraged negligible connection damages and an economical tubular asset life. However, with the increasing prevalence of horizontal wells, premature tool joint downgrade has accelerated asset turnover drastically destabilizing the rental industry balance.

The fundamental driving mechanisms behind this shift are the predisposition of tubing to lie on the low side of the casing, due to gravitational forces, as well as axial compression as tubing is conveyed through the curve and lateral. As the string undergoes compression in the lateral, the tubing becomes prone to deformation via sinusoidal and helical buckling. These combined effects promote undue contact force between the tool joint upset and casing wall. As the tubing string is rotated through highly deviated wellbores, these contact forces induce rapid tool joint degradation, ultimately leading to premature tubing downgrade. A supplemental contributor to premature downgrades is the finite available upset length for re-cuts, which limits the serviceable length for box and pin thread repairs prior, to downgrade.

Historical data gathered by Certus Energy Solutions suggests that, on average, 10% of PH-6 joints are retired upon post-rental inspection due, to premature tool joint downgrades. Assuming a standard 18,000-ft rental string, the downgrade cost alone is in excess of $30,000 per inspection. Extrapolating that figure for a 40-well cleanout program, at four wells per inspection, equates to over $300,000 in replacement costs, alone. This scenario is detrimental to both producers and rental companies, as operators are forced to finance the replacement of tubing with negligible impairment of the tube body itself.

The mechanical limitations of standard-use tubing are of increasing concern in the era of extended lateral drilling. The same contact forces that promote tool joint degradation also impart frictional drag on the tubing string as it progresses through the well. In extended lateral wells, the moderate torsional ratings of PH-6 and similar connections often constitute the lower limit of what is required to overcome frictional loss and effectively drill out plugs near the toe. Progressively, operators must compromise between connection torque and hydraulic efficiency, as heavy-walled tubing or drill pipe is the only current method of improving torsional values. Both are equally significant, as higher circulation rates are necessary to effectively remove debris from the wellbore.

THE HZT WORKSTRING CONNECTION

Forced to reconcile with the issues facing the workstring tubular industry, Certus set out to engineer a remedy. In 2015, the company commissioned a project to develop a non-upset tubular connection that would eliminate all the aforementioned limitations of PH-6 tubing. By analyzing the underlying issues of the two-step connection, the company was able to design a fit-for-purpose connection, tailored to horizontal well intervention.

Design progression. During product development, finite element analysis (FEA) was utilized to design a proprietary, tapered-thread form, capable of developing full pipe body tensile capabilities while maximizing the cross-sectional area available for a torque shoulder. At each stage, Von-Mises stresses were examined, to evaluate the thread form and overall connection performance, providing a mathematical analysis of all stresses acting on the load-bearing elements. After the initial design phase, prototypes were manufactured and put through various physical testing mechanisms, to validate connection performance.

Due to limited wall thickness afforded by the non-upset design, a reduced thread height and taper were selected to optimize stress distribution of the torque shoulder. The stabbing flank angle was chosen to provide a reasonable enough taper to prevent thread-catching during stabbing while maximizing thread width to prevent stripping. Considerable time was taken in optimizing the load flank angle, as it is the primary mechanical engagement between box and pin, and thus bears the tensile load during downhole operations. The load flank angle was selected to optimize stress flow while minimizing the proclivity for thread jumping and stripping. Additional topping and kick-out features were added, to promote separation of the pin and box during break-out.

In an effort to ensure the reliability of the sealing element over multiple make-up and break-out cycles, the seal and torque stop features were designed to function independently, yet complementary. The seal was set at a forward taper, to maximize sealing surface and develop contact stresses during connection rotation. The torque stop angle was optimized to prevent swaging of the pin nose while undergoing radial compression via rotation. The combination of these features resulted in an optimally balanced connection, capable of consistent performance over multiple make-and-break cycles, Fig. 2.

BENEFITS OF HZT CONNECTION

The chief benefit of the HZT connection over current industry standards is the utilization of a disposable coupling, which, when worn beyond OD tolerance, can be replaced without sacrificing the entire joint. At current market prices, The HZT coupling can be replaced at roughly 25% of the cost of a downgraded joint of tubing. By separating the tool joint from the tube body, the tube body, itself, becomes the determining factor in the tubing life cycle. In addition, the tight tolerances and optimal thread design of the HZT connection decrease the propensity for galling, thus minimizing re-cut occurrences and saving producers additional repair expenses. Finally, because HZT does not rely on an external upset to achieve performance values, the pin can be redressed for an infinite number of times.

By leveraging an internal torque shoulder to maximize the cross-sectional area available for stress distribution during makeup, the connection allows for up to 77% higher torque capacity than standard connections. The maximum allowable make-up torques for 23/8-in., 5.95 lb/ft (Fig. 3) and 27/8-in., 7.90 lb/ft P-110 tubing are 6,000 ft-lbs and 6,900 ft-lb, respectively. HZT’s unique thread profile and optimized flank angles allow for a connection efficiency in excess of 120% of the tube. The connection also boasts a flush-to-tube ID for improved hydraulics and a gas-tight metal-to-metal seal rated to 10,000 psi. These properties make this new connection ideal for extended lateral workover operations.

Since commercializing the product in 2016, Certus has established a separate manufacturing division, in an effort to share its product directly with operators and rental companies. Through Certus Manufacturing, customers can apply the HZT connection directly to plain-end tubing or convert their previously downgraded upset tubing. The retrofitting process is ideal for customers with existing downgraded inventory due to upset OD wear, as the tube body, itself, is typically well within operational limits. At current market prices, new HZT prices are comparable to two-step, and conversion costs are roughly 60% that of a new joint of PH-6.

FIELD TRIALS

Since initial product roll-out in April 2016, the connection has proven its resiliency in field trials across several U.S. shale plays. To date, case studies have been conducted in the Permian, Williston and DJ basins, with a 100% operational success rate. Results of these trials have proven consistently that the new connection significantly minimizes repair charges by eliminating tool joint downgrades and greatly reducing connection re-cuts.

One notable case study was conducted with an operator in the Williston basin of North Dakota. The trial consisted of a four-well drill-out, utilizing a 23/8-in. HZT by 27/8-in. PH6 split-string design, and well depths ranging from 20,900 ft to 23,250 ft. The customer had been averaging 60 downgrades and 150 re-cuts during similar operations and trusted that the new connection could mitigate these damages. Post-trial results found that HZT was able to reduce damages to three downgrades (due to slip-area damage) and four re-cuts, resulting in a 96% reduction in repair costs. A subsequent four-well trial yielded zero downgrades and 11 re-cuts. Thus, the operator was able to reduce damage expenses by more than $75,000 over an eight-well period.

Additional field trials have included snubbing and fishing operations, as well as wellbore clean-outs through mechanical sleeves. To date, successful trials have been conducted with both 23/8-in. and 27/8-in. HZT tubing. Future projects include a 28,000-ft, MD, drill-out to be performed during August 2017.

A TUBULAR STEP CHANGE

As the first workstring connection designed specifically to meet the economic and operational challenges posed by horizontal well intervention, the HZT connection may represent a paradigm shift in tubular technology. With more than 400,000 ft in run footage, 499 plugs drilled to date, zero replacement couplings attributed to OD wear, and an average re-cut rate of 0.57%, HZT tubing has proven its reliability and cost-effectiveness in horizontal well environments. With the ability to revive previously downgraded assets, prolong the tubular life cycle, and balance torque capacity with hydraulic efficiency, this tubular product is showing great flexibility. ![]()

ACKNOWLEDGEMENT

The author would like to thank Adam Williamson, product line manager, for producing the artwork and tool renderings contained in this article.

- What's new in production (February 2024)

- Using data to create new completion efficiencies (February 2024)

- U.S. operators reduce activity as crude prices plunge (February 2024)

- U.S. producing gas wells increase despite low prices (February 2024)

- U.S. oil and natural gas production hits record highs (February 2024)

- Dallas Fed: E&P activity essentially unchanged; optimism wanes as uncertainty jumps (January 2024)