Completion capabilities expanded by ball-activated technology in Argentina

Packers Plus has been at the forefront of multi-stage ball-activated completions in Argentina since 2007. The company’s StackFRAC system has been deployed in more than 35 wells, with more than 200 stages being stimulated successfully in the region—the most of any open-hole completion system in the country.

Argentina is home to one of the world’s most prolific unconventional hydrocarbon resources, known as the Vaca Muerta play in the Neuquén basin. The country has 10% and 8% of the world’s technically recoverable shale gas and oil reserves, and is ranked third and fourth worldwide, respectively. An analysis by Wood Mackenzie shows that 2015 production from the Vaca Muerta formation is expected to double by 2018 as more projects come online.

As development of this vast resource continues, the vendor is enabling operators in Argentina to go beyond conventional operations and stimulation techniques to improve completions practices.

Thirty-fold reduction in completion time. One of the completion methods used by operators in Argentina is the coiled tubing plug-and-perf technique, requiring multiple trips, in and out of the hole, to run in bridge plugs and fire perforations. Accordingly, an operator working in the Loma La Lata gas field was looking for a faster completion system that would stimulate multiple stages.

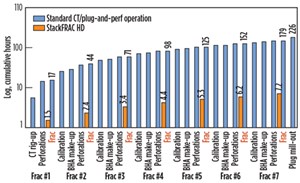

Choosing the StackFRAC HD system to complete the well, the operator installed seven stages on a 4.5-in. liner. The system stimulates the reservoir by sequentially pumping balls of incrementally larger size from surface in a single, continuous pumping operation, thereby mitigating the operational risks associated with wireline intervention or coiled tubing. Without the need for intervention, the time, and cost, of stimulation operations is greatly reduced.

Typical plug-and-perf completions also require plugs to be milled out after stimulation, but the balls in a ball-activated completion system can be flowed back immediately if desired. This minimizes reservoir damage, due to fracture fluids sitting on the formation.

The stimulation program for the seven-stage well took approximately 7 hr, with an average of one stage per hour. In comparison, using the coiled tubing plug-and-perf technique would have taken an estimated 226 hr, or over 9 days, assuming a smooth operation. This equated to a stimulation operation more than 30 times faster, saving the operator thousands of dollars.

Most ball-activated stages in Argentina. In early 2015, Packers Plus installed a StackFRAC system with an operator in the tight dolomite, Loma Montosa formation on the Puesto Morales Block for a horizontal well test. The operator stated in a press release that this was the first 12-stage ball-activated system that was stimulated in Argentina.

Twelve stages were stimulated in just 6 hr. The well was treated with a hybrid slickwater/gel fluid, with a total of 10,900 bbl of water, as well as 360 tons of sand pumped.

Multi-stage stimulation of a vertical well. Another well installed in the tight Agrio formation of Curamhuele field, in early 2016, was the first in the country to use an open-hole, ball-activated multi-stage system in a vertical well, along with a stage collar above the system to cement the casing back to surface. The four stages of the stimulation system were treated at a high rate of 62 bpm and treating pressures of 11,000 psi, using degradable balls.

Continued expansion and future work. Building off its early success in Argentina, Packers Plus expanded its presence in the country with the opening of a service and a sales center in Neuquén and Buenos Aires, respectively. The service center is 30,000 ft2, and capable of housing systems and components that are built, and sent, from manufacturing centers in North America. The service center is able to perform manual assembly, torque and testing, on all systems leaving the facility.

This expansion serves as a base for the continued evolution of completion practices in Argentina. As part of its future work, Packers Plus has developed a line of ball-activated, cemented liner completion solutions. This line of cemented completion technology includes single-point entry sliding sleeves, limited-entry sliding sleeves, a premium liner hanger system and toe sleeves. These new technologies have been successfully field trialed in North America and will be applicable to the market in Argentina, providing an avenue for continued completion innovation. ![]()

REFERENCES

1. MacNeil, A., and M. Vacy-Lyle, Oilfield Services Weekly, AltaCorp, Alberta, Calgary, Sept. 13, 2016.

2. Ainsworth, K., “Shale, tight gas production from Argentina’s Neuquen basin on the rise, while Venezuela suffers dramatic production declines,” Drilling Contractor, Aug. 26, 2016.

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)