OTC Spotlight on New Technology Awards: Innovations focus on reliability

When it comes to offshore and subsea technology, the operative word is reliability. On May 2, the Offshore Technology Conference (OTC) will formally honor 13 innovative technologies via its 2016 Spotlight on New Technology Awards. The winning technologies cover the full spectrum of activity, from cement evaluation to oil/water separation, from ROVs to subsea controls. The winning companies range from international technology giants to smaller, more specialized firms. For a second consecutive year, the awards will also recognize technologies developed by small businesses, those with 300 or fewer employees, via the Spotlight on Small Business Award.

RISER GAS HANDLING SYSTEM

Mitigating risk and developing more efficient technologies is crucial to any deepwater drilling operation. AFGlobal’s next-generation Riser Gas Handling (RGH) system features a unique, purpose-built design that offers simplicity, flexibility, and reliability for today’s dynamically positioned and moored rigs. The RGH equipment safely circulates gas out of the riser and diverts flow; using real-time monitoring and control, potentially dangerous riser events can be avoided. The system allows mitigation of gas influx through normal means, as opposed to unloading the riser, which could mean returning as much as 150,000 gal of drilling fluids to the ocean. The RGH system handles retrofit and newbuild applications, using specialty riser joints and equipment. The RGH system is said to be the first system fully capable of autonomous operation to control flow distribution without an RCD. To date, the system has been deployed successfully in several regions.

INTEGRITY EXPLORER CEMENT EVALUATION SERVICE

A full description of this winner from Baker Hughes is available here.

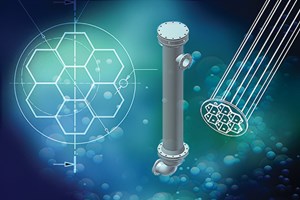

INLINE ELECTROCOALESCER

FMC Technologies’ InLine ElectroCoalescer enables efficient oil/water separation of medium and heavy oil. The InLine ElectroCoalescer is a compact, pipe-based technology that uses a high-frequency, alternating current with high voltage to polarize, coalesce and enlarge water droplets, which can then be separated much faster in the downstream separation equipment. Installing an InLine ElectroCoalescer upstream of a separator greatly increases the capacity of that separator.

In older facilities, this results in debottlenecking, reduced demulsifier injection or decreased energy consumption of the heating system. For greenfield applications, this means the size of the separator and the use of demulsifiers can be greatly reduced. The InLine ElectroCoalescer is compact itself—one-half to one-fourth the size and weight of other electrostatic coalescers. This footprint reduction makes it ideal for installation in deepwater subsea processing systems.

SEAPRIME I SUBSEA CONTROL SYSTEM

A full description of this winner from GE Oil & Gas is available on here.

AQUAWATCHER WATER ANALYSIS SENSOR

A full description of this winner from OneSubsea is available on here.

BARALOGIX REAL-TIME AND AUTOMATION SERVICE

The BaraLogix Density & Rheology Unit (DRU) from Halliburton, is an autonomous, computerized device that allows real-time measurements of fluid density and rheology, combined with trending analysis, visible to the well construction team. The DRU fluids optimization service helps reduce risk by, providing more frequent data collection than manual mud checks, providing more accurate downhole modeling to ensure safety margins. Real-time data acquisition helps ensure consistent fluid properties and reduce the potential for NPT. The real-time data can be interpreted to proactively make adjustments and optimize the drilling program.

ROPE AND WINCH SYSTEM FOR DEEPWATER DEPLOYMENT

Lankhorst Ropes introduced the LankoDeep AHC Soft Rope System, a collaboration between Lankhorst Ropes, Deep Tek, and DSM Dyneema. It can handle heavy loads at water depths greater than 3,000 m. The system incorporates Dyneema’s DM20 XBO synthetic filament, optimized for cyclic bending with a proprietary rope coating technology. The new-style rope has 12 stranded braids for additional strength.

This construction, combined with the DM20 coating, helps reduce the tension required to bed-in the rope, as well as reducing internal heating and abrasion. The rope can be inspected and repaired, if damage is discovered. The other element of the heavy-load handling system is a Deep Tek drum winch, with multi-layer chevron spooling capabilities optimized for offshore crane systems.

DROPPED OBJECT PREVENTION PROGRAM (DOPP)

Dropped objects are a serious hazard in the industry, and DOPP was designed specifically with that in mind. The OES Oil Field Services program supports and enhances the delivery of a dropped objects prevention plan.

The four stages include Stage 1, a rig-specific dropped object evaluation health check; Stage 2, a rig-specific dropped object awareness training program; Stage 3, a tablet-based dropped object application; and Stage 4, handover of rig-specific tablet application.

By incorporating the tablet application, the program can build an inventory of permanent and temporary equipment on the rig, which, ultimately is handed over to the crew as a real-time reference.

BPRs PREVENT UNCONTROLLED CHEMICAL DELIVERY

SkoFlo Subsea Back Pressure Regulators (BPRs) are anti‐siphoning, self‐regulating devices that create back pressure in chemical injection lines to prevent uncontrolled delivery of chemicals into production wells. BPRs prevent chemicals from draining into injection points, when a chemical hydrostatic head exceeds injection pressure and production wells become sub‐ambient. The novelty of this device is that it regulates its inlet pressure when the well pressure falls below the factory set point. It achieves this regulation with a simple clog-resistant mechanical device, without power or communication.

For green fields, BPRs can be used for future, low well pressures in deep water and typically start service without regulating pressure. For brown fields, BPRs can be used for old wells, which have reduced pressures, without interfacing to the control pod. They can be installed on subsea trees, manifolds, logic caps and MQC plates.

REMOTE PILOTING, AUTOMATED CONTROL TECHNOLOGY

Oceaneering has introduced two new technologies that greatly increase ROV operational efficiency and reduce costs. During a demonstration in the Gulf of Mexico last October, the NEXXUS ROV was piloted successfully via a satellite link from an onshore base. With this technology, experts or other pilots can be linked-in, in the event of highly complex processes or technical procedures that require special knowledge.

The demonstration also included a hands-free operational method of piloting. Rather than using a joystick, the pilot is able to operate the ROV with a command-based system, involving automated steps. With Video Machine Vision Technology, the video processing software analyzes video and sends the ROV control system positioning data from the video, to control the thrusters and move the ROV.

HYFLEX SUBSEA TREE SYSTEM

Based on existing field-proven conventional subsea tree components, the HyFleX subsea tree system from OneSubsea, a Schlumberger company, is designed with the tubing hanger completely independent of the tree. This provides flexibility in installation sequence and workover operations, resulting in lower CAPEX and OPEX.

Because of the independent configuration of the three main assemblies—the tubing head spool, the tree and the tubing hanger—system components can be installed like a conventional horizontal completion, or like a vertical subsea tree.

Key advantages of the system include the mitigation of risk; a shorter time to well completion; low overall lift weight; and low tree workover costs.

ELECTRICAL OPTICAL FLYING LEAD

Traditionally, flying leads have been considered a passive element in subsea infrastructure. Teledyne Oil & Gas has developed a technology platform to evolve its role. The firm has integrated electronics into a connector or inline with the jumper, transforming the flying lead into an active component in a subsea data transmission system. The Electrical Optical Flying Lead (EOFL) features a Nautilus Rolling Seal Hybrid connector on one side, and a 7- or 12–way Nautilus electrical connector on the other, with a qualified, integrated electrical/optical converter within the pressure balanced, oil-filled hose. Suited for connectivity on subsea control modules, data transmission systems, umbilical terminations, electrical junction boxes and other subsea structures, the EOFL converts an electrical signal to a fiber optic signal.

MOTION-COMPENSATED LIFTING FOR OFFSHORE TRANSFER

The BM-T40 offshore crane from Barge Master BV is designed for maintenance support vessels and platform supply vessels. These vessel types are used to transfer small loads or personnel to (unmanned) offshore oil and gas platforms. This motion-compensated crane enables personnel to lift items safely from a moving vessel to an offshore installation. This equipment eliminates motions at the base of the crane, allowing work to continue safely in higher sea-states, eliminating the need for platform cranes while reducing costs significantly. The BM-T40 has a small footprint and can compensate for sea-induced motions of a knuckle boom crane with a lifting capacity of 15 mT at a 10-m radius, or 5 mT at a 20-m radius. ![]()

- Coiled tubing drilling’s role in the energy transition (March 2024)

- Advancing offshore decarbonization through electrification of FPSOs (March 2024)

- What's new in production (February 2024)

- Subsea technology- Corrosion monitoring: From failure to success (February 2024)

- Digital tool kit enhances real-time decision-making to improve drilling efficiency and performance (February 2024)

- E&P outside the U.S. maintains a disciplined pace (February 2024)