What's new in exploration

Since we just finished the largest oil and gas “show, convention and technology display” on the planet, the Offshore Technology Conference (OTC) in Houston, I thought that it is time to use the word, “Unconventional.”

During 1980, I was once a project manager of an in-situ oil shale retort project. We were looking at reverse osmosis at the nano level, yet little did we (or I) imagine that someday, major oil companies would be looking at recovery from nano-Darcy perm. Robert (Loucks et al. 2009) also found that gas shale strata are composed of micro- and nanopores, with the majority being nanopores. These facts emphasize the importance of studying how gas flows in nanopores or nanotubes, which will be critical for shale gas stimulation and effective commercial production. (see http://petroleum.mines.edu/research/emg/SPE_papers/SPE-167179-MS.pdf). Don’t be surprised when you find someone is looking at pico-Darcy perm shale, below the diameter of a methane molecule.

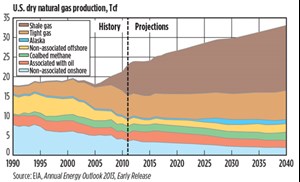

I would like to point out that RPSEA has been studying shale, hydraulic fracturing and frac water disposal onshore since 2006, near the beginning, on the cutting edge—the “I told you so” part of the unconventional boom timeline, as noted on the USEIA graph. RPSEA projects are all selected by our industry partners. A list can be found at: http://www.rpsea.org/projects/search/?q=&program_year=&program=2&project_status=.

What’s new? I note a few projects that have immediate 2015 exploration value.

Petrophysics and Tight Rock Characterization for the Application of Improved Stimulation and Production Technology in Shale; 2011 Unconventional Resources; Project Number: 11122-63; Project status: June 27, 2013; End date: June 26, 2015; Investigator: Jim Puckette, Oklahoma State University.

This project is to improve understanding of rock-fluid interactions in shale, to improve petrophysical characterization methods and propose standards for shale analysis, and to develop methodology for the selection of fracturing fluids and additives. Specific objectives include 1) developing techniques, workflows, and best practices for the petrologic and petrophysical characterization of shale; 2) proposing analytical standards for porosity and permeability measurement in shale, similar to those that exist for conventional reservoirs; 3) exploring techniques to characterize shale microstructure; 4) characterizing interactions among rock, reservoir fluid, stimulation fluid, and additives; and 5) developing techniques to rapidly evaluate stimulation fluids and additives.

Conductivity of complex fracturing in unconventional shale reservoirs; 2011 Unconventional Resources; Project Number: 11122-07; Project status: June 26, 2013; End date: June 25, 2015; Principal investigator: Ding Zhu, Texas A&M Engineering Experiment Station (TEES).

The objective of the research is to conduct a systematic, experimental study of fracture conductivity in shale oil and gas formations. The study focuses on the conductivity behavior of shales from three formations, namely the Barnett, Fayetteville and Eagle Ford shales. Outcrops and cores from the three shales were collected, a systematic experimental condition was designed, and conductivity under different closure stresses was studied, by flowing either gas or liquid through the test cells. Both propped and un-propped fracture conductivity were examined, and the effect of proppant type, size and concentration analyzed in the study.

The effect of natural fractures, proppant type, size and loading, closure stress, and rock mechanics properties, on fracture conductivity, was examined in the project. An understanding of fracture conductivity behavior in different shales was further evaluated by performance prediction, with simple models to explain the observation and support the findings from the experimental study.

And lastly, here’s a quantitative beginning to useful microseismic understanding from active, 3D seismic analysis: Multi-azimuth Seismic Diffraction Imaging for Fracture Characterization in Low-Permeability Gas Formations. 2008 Unconventional Resources; Project Number: 08122-53; Project Status: completed; Principal Investigator: Sergey Fomel; The University of Texas at Austin

The projects’s objective was to create predictive seismic technology for fracture detection, using P-wave diffraction imaging, and test it against realistic fracture patterns. Also, the project examined sidewall-core and wireline-based methods that can be used to verify this “new” seismic approach. Both methods were tested to verify that they work in an exploration and production setting.

Correction from last month: The marine mitigation estimate is a whopping $105 million/year, not $1.05 billion. ![]()

- Shale technology: Bayesian variable pressure decline-curve analysis for shale gas wells (March 2024)

- Prices and governmental policies combine to stymie Canadian upstream growth (February 2024)

- U.S. producing gas wells increase despite low prices (February 2024)

- U.S. drilling: More of the same expected (February 2024)

- U.S. oil and natural gas production hits record highs (February 2024)

- Quantum computing and subsurface prediction (January 2024)