The 2014 World Oil Awards honored “Groundbreaking Strides in the Oil and Gas Industry.” The goal of the World Oil Awards is to recognize innovations and innovators, and the companies and their people, that create and develop the technologies that drive the industry to higher plateaus.

The 13th annual World Oil Awards honored winners and finalists in 16 categories, covering the spectrum of the upstream oil and gas industry. This year’s winners took home trophies at The Houstonian Hotel on Oct. 16. The evening’s master of ceremonies was Shara Fryer, the morning anchor on NewsRadio 740 AM in Houston. James Pappas, acting president of RPSEA, opened the ceremony with a keynote addressing industry ethics.

The 2014 awards were sponsored generously by Saudi Aramco, Baker Hughes Incorporated, Eddie V’s, Fairmount Santrol and Halliburton. A/V services were provided by Puresound, and event photography was provided by Gary Barchfeld.

The World Oil Awards endow leading universities with much-needed funds and encouragement to educate the industry’s future leaders. The recipient of this year’s university endowment was the University of North Dakota’s College of Engineering and Mines.

On behalf of the World Oil Awards advisory board members, Gulf Publishing Company and World Oil, congratulations to this year’s winners and finalists. Your commitment to revolutionizing the industry with cutting-edge technology and innovative ideas will continue to inspire your peers and the next generation of leaders.

JUDGES

The judging process for the World Oil Awards is conducted by an esteemed advisory board, made up of leaders in the industry, with a diverse range of expertise. To ensure objectivity, all submissions are scored by a minimum of three judges, none of whom can be representatives of any of the submitting companies in the categories that they judge.

ADVISORY BOARD

The 2014 World Oil Awards advisory board consists of well-known energy industry leaders and helps judge the short list of nominations.

Pradeep Anand, President

Seeta Resources LLC

Ron Bitto, Principal

Bitto Marketing Consultants LLC

Dr. Ali Daneshy, President

Daneshy Consultants International, Inc.

Deepak Gala, SME-Well Control Engineering

& Relief Well Planning Shell

Dr. Helge Hove Haldorsen, Vice President, Strategy and Portfolio, and Mexico Country Manager

Statoil Development and Production North America

Brian Morr, President

Technosphere, Inc.

Dr. William Pike, Managing Consultant

Leonardo Technologies, Inc.

Contractor to National Energy

Technology Laboratory

U.S. Department of Energy

Bob Schwartz, President

RHS Consulting LLC

Earl Shanks, OIE Chief Technologist

Oceaneering International, Inc.

BENEFICIARY UNIVERSITY

In 2012, North Dakota became the second-largest oil-producing state in the U.S. and, in 2014, achieved the production of 1.0 MMbpd. Advances in recovery methods from the huge reserves of North Dakota’s Williston basin contributed to this growth. The World Oil Awards recognized the work of UND’s College of Engineering and Mines with an endowment. UND will be instrumental in continuing the professional education of domestic and international students, who are preparing for a career in petroleum engineering, as well as in the fields of chemical, civil, electrical, geological and mechanical engineering. In just two years, the program has grown from four students to an estimated enrollment of over 300 for Fall 2014.

KEYNOTE SPEAKER

James Pappas, acting president for the Research Partnership to Secure Energy for America, delivered the keynote speech at the 2014 World Oil Awards. RPSEA’s mission is to provide a stewardship role in ensuring the focused research, development and deployment of safe and environmentally sensitive technology that can effectively deliver hydrocarbons from domestic resources to U.S. citizens.

Taking the podium at the awards show, following a state-of-the-market address from World Oil publisher Ron Higgins, Pappas discussed matters of business ethics, as they apply to the E&P industry.

Ethics, he said, are the principles of conduct that govern people, concerned with moral standards that any rational adult might have, that are culturally universal. “We live by the Golden Rule: treat others as we, ourselves, would like to be treated,” Pappas remarked. “Ethics determine what are and are not reasonable standards of moral behavior. We have micro-ethics, which deal with the individual, and macro-ethics, which are concerned with systems and what is right, or what ought to be right.”

Pappas discussed misconceptions of ethics, which he said arise when someone deems that all ethical problems have right and wrong answers, a black or white perception. An image of a shining knight on a white horse coming into town to save the day appears “good,” Pappas evoked. But reasons for unethical behavior, such as greed, can cut a distinction on how one acts in his or her personal life, compared with his or her business life. There can be no difference, Pappas said. Dilemmas exist externally, such as unethical products, sales practices, manipulative advertising or polluting the environment, as well as internally within organizations.

Ethics can be taught with values, through formal education or through reconceptualization. We grow up out of premature stages, once we get to our 20s and 30s, Pappas said. Sources of ethics teaching include organized religion, education, civic organizations and government, and family. “Family is our first form of values that instills ethics … our values influence both ethics and morals,” Pappas said. “Not all laws are ethical, as law is reactive to circumstance. Ethics is proactive.”

Foundation principles of business ethics are confidentiality, acting in good faith when negotiating, avoiding the appearance of a conflict of interest, respecting rights and liberties, and willful compliance with the law. “People are walking bundles of habits,” Pappas said. “The key is to follow the right habits, learn the correct habits early, strengthen your weaknesses, and build on those grounds of moral behavior.”

Pappas noted an example, where people were telling white lies at the sales level. “We spoke to their management team, explained it in black and white, and we felt the sales team was guilty,” Pappas said. Action was taken, he added, by notifying the operator that sponsored and oversaw the project.

BEST COMPLETION TECHNOLOGY

This award recognizes the leading solution that provided a substantial impact on the industry’s completions. Criteria for the award include innovation, reliability, commercial application and industry impact.

Winner: Multi-stage Unlimited Frac Isolation System, NCS Energy Services

The first commercially successful multi-stage comple-tion system combines cemented casing sleeves with a coiled tubing-deployed completion assembly, to enable single-point injection from horizontal wells. The system uses about a third of the pumping horsepower needed for plug-and-perf and ball-drop sleeves. Fewer frac units equal lower equipment and fuel costs; a smaller wellsite footprint; fewer personnel; less traffic, noise and exhaust; and lower overall costs. Production increases have ranged from 73% in the Bakken, to 100% in the Permian basin and Granite Wash, to 200% in the Permian basin (gas). The system detects and records pressure communication between stages, so operators can optimize spacing in subsequent wells for the best reservoir contact. The system has been used for completions exceeding 90 stages, with frac spacing as close as 60 ft. Tighter stage spacing is an increasingly important tool for improving stimulation results. Single-point injection enables control of frac volume to prevent frac growth into neighboring wells, water zones, or other formations, when no natural frac barriers exist. With real-time, frac-zone pressure data (via the coiled tubing), operators can observe frac progress, and adjust pump rates and sand loading to avoid premature screen-outs. At the same time, screen-outs can be circulated out quickly, allowing the use of aggressive sand loadings to increase production. Circulation capability reduces the amount of water pumped into the formation and overall water usage. Completions are fast and sure, with no guesswork. Typical time to locate and shift sleeves is 9 min. The wellbore is fully open and production-ready, when the completion assembly is removed. Cemented sleeves allow wells to be economically restimulated.

Finalists:

- BroadBand Sequence Fracturing Service, Schlumberger

- Mangrove engineered stimulation design in the Petrel platform, Schlumberger

- Propel SSP™, Santrol

- StackFRAC®(SF) Cementor™, Packers Plus Energy Services Inc.

- SmartWell®Electro-Hydraulic Disconnect Tool, Halliburton

- ZoneSelect® Multizone Completions Systems SMART Toe Sleeve, Weatherford

BEST DATA MANAGEMENT & APPLICATION SOLUTION

This award is given for an implemented, viable workflow solution, focused on data storage, delivery or management processes and technologies, that provided tangible results for an operator or service company.

Winner: DecisionSpace® G1 Personal Edition, Halliburton

This software cuts E&P companies’ data management activities by enabling work on multiple, complex, conventional or unconventional plays, onshore or offshore, in either time or depth, to integrate and interpret across multiple seismic surveys, to locate sweet spots, and new or bypassed pay, from anywhere in the world. DecisionSpace G1 Personal Edition is the first and only complete geoscience interpretation package built on a zero-configuration, OpenWorks-compliant, embedded database. Accordingly, this new technology enables an individual geoscientist or reservoir engineer to work multiple, complex, conventional or unconventional plays. E&P companies are already seeing immense efficiency gains in their exploration and development programs, utilizing one complete interpretation system and database. By removing the numerous stand-alone files through use of G1 Personal Edition, these E&P companies can, potentially, cut the data management activities of their geoscientists by as much as 90%, freeing up that resource to uncover new prospects or perform greater analysis on existing ones. The embedded database also delivers security and backup capabilities not otherwise available in one package, helping to ensure data are protected, even if the computer is lost, stolen or damaged. Using DecisionSpace G1 Personal Edition, an operations geoscientist at the rig site, onshore or offshore, now has the ability to go from installation, to secured data loading, to full three-dimensional, real-time interpretation, in less than 30 min. This is time that can be critical when drilling is nearing offset wellbores, approaching hazardous faults, or getting close to the target reservoir.

Finalists:

- Box/Prontoforms, Royal Dutch Shell

- DecisionSpace® GRC (Government, Risk and Compliance) Well Construction Software, Halliburton—Landmark Software

- JewelSuite™ GeoMechanics Fully integrated workflow, Baker Hughes Reservoir Software

- SeaLytics™ BOP Advisor, GE Oil and Gas

- Shale Asset Workflow Solutions (SAWS™) Discovery Tool, Baker Hughes

BEST DEEPWATER TECHNOLOGY

This award recognizes significant technology in the area of drilling, completions and production in deepwater applications.

Winner: BRIMSTONE™ well barrier, Baker Hughes

This setting tool enables shoe track isolation at ultra-HPHT conditions, and can deliver the minimum required setting force with hydrostatic pressures as low as 16,000 psi and as high as 35,000 psi, and with temperatures up to 500°F. Achieving a competent primary cement job on the shoe track in an ultra-HPHT well is difficult, and frequently results in a wet shoe. When this occurs, the shoe track must be isolated before completion or other post-cementing operations can begin. Retrievable service packers and cement retainers are generally not available to squeeze a wet shoe at ultra-HPHT conditions. However, the 500°F temperature rating and 25,000-psi differential pressure rating of the BRIMSTONE well barrier enables shoe track isolation at ultra-HPHT conditions. Today’s HPHT muds and completion fluids are very aggressive toward elastomeric materials and many steels, presenting tremendous materials challenges to downhole tools. And when operating in these environments, only FFKM elastomeric materials can provide long life downhole. The BRIMSTONE well barrier is a life-of-the-liner design, and is qualified to the V0 standard of ISO 14310 (API 11D1) at 500°F and a differential pressure of 25,000 psi. Because of these features, the BRIMSTONE well barrier can be relied upon for shoe track isolation without the use of cement on top of it. Further, ultra-HPHT environments place harsh demands on running tools, wireline cable, and related wireline tools. A new high-performance E-line-conveyed hydrostatic running tool has been developed to convey the plug into ultra-HPHT wells. These two tools have deployed successfully multiple times in the Gulf of Mexico. One operator was able to begin the completion of a well at 470°F with the added reliability of a secondary barrier.

Finalists:

- Enhanced Fatigue Monitoring System, Stress Engineering Services Inc.

- Rhino RHE Dual-Reamer, Rathole Elimination System, Schlumberger

- UltraConnect 35K HPHT perforating system, Baker Hughes

BEST DRILLING & COMPLETIONS FLUIDS

This award category recognizes an innovation drilling or completions fluid, or a fluid-related mechanism or process that was commercially introduced within the last year, and which helped to drill for, or produce, oil or gas.

Winner: SentinelCem™ Cement, Halliburton

Lost circulation is reported as one of the most costly problems during drilling operations. Costs range from several thousand dollars for moderate fluid loss to tens of thousands of dollars for sidetracks or relief wells resulting from severe losses. If remediation solutions are ineffective, significant financial setbacks occur, due to bypassed reserves or even cancelation of development projects. Fractured, vugular or highly-porous formations generally have high permeability and/or large openings that can rob considerable volumes of drilling fluid. When this occurs, particulate materials are not likely to successfully address the problem. In such cases, further drilling is impeded, and the expense of setting additional casing strings or abandonment of the well may be required. SentinelCem™ cement, designed to address lost circulation, has a shear-rate-dependent rheology. When the shear rate is high, the viscosity is low, and the slurry flows easily for placement. Flow into formation openings reduces the shear rate. When the shear rate is reduced, as happens when it enters thief zones, the slurry thickens and gels, resisting slurry flowback, fall-back or formation influx. This unique property of gaining early gel strength and compressive strength, when the shear is reduced, helps cure losses. The slurry will become liquid again, for a few cycles, if the shear is re-applied. The features, such as thixotropy, bonding, and dynamic pumping time, independent of temperature, increase the probability of curing the losses with this cement system. This solution helps manage operational costs by minimizing loss of fluids and allowing drilling to continue. Acid solubility enables optimally oriented perforations and stimulation treatments.

Finalists:

- BaraPure™ salt-free, high-performance, oil-based fluid system, Halliburton Baroid

- BREAKDOWN HD filter cake breaker system, M-I SWACO, a Schlumberger company

- ClearStar™ fracturing fluid system, Baker Hughes

- INDEFLOC, PDVSA INTEVEP

BEST DRILLING TECHNOLOGY

This award goes to innovators, who executed an industry-leading effort during the year that had a significant impact on the industry, onshore or offshore, through drilling innovation.

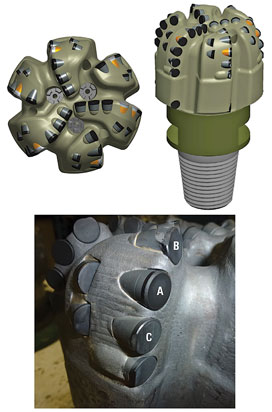

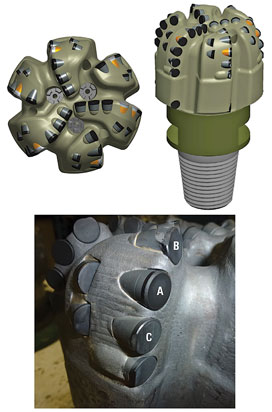

Winner: ONYX 360 rolling PDC cutter, Smith Bits, a Schlumberger company

For more than 40 years, the bit industry has been constrained by the paradigm of “fixed cutters” in PDC bits. With its unique ability to rotate while drilling, the ONYX 360 cutter technology offers a step change in bit performance over conventional fixed cutter bits. Prior to the introduction of the rolling cutters, only marginal results characterized bit-wear improvements across the industry. While ONYX 360 penetration rates have improved for a wide variety of formation types, the biggest impact is the reduction of trips to change out worn bits. In deepwater wells, a single bit trip can cost in excess of $1 million. Not only is considerable time saved, but with its greatly improved life, the ONYX 360 bit can have a major effect on risk reduction. An Australian offshore operator needed to drill an 8½-in. vertical borehole through the extremely hard and abrasive Plover formation, characterized by short bit runs of about 40 m and very low ROP. Stick-slip torque affected BHA reliability and wellbore quality. Using the IDEAS integrated design platform, engineers from Smith Bits placed two 13-mm ONYX 360 cutters on each of the eight bit blades, at the high-wear shoulder position. The operator wanted to run a combination of rolling PDC cutters and conventional PDC bits, to compare performance and quantify any improvement in the same wellbore. After a trial run, engineers made adjustments to the bit and operating parameters that allowed the ONYX 360 rolling cutter bit to drill the entire Plover interval, in a single run, at 30.4 fph, 286% faster than the fastest conventional bit. An offset well required four standard PDC bits to drill the same section, and added trip time cost the operator $1 million. The rolling cutter has substantial untapped potential. Design engineers are working to further optimize bit designs, to take full advantage of these rolling PDC cutters’ superior resistance to bit wear and excellent heat dissipation.

Finalists:

- Bottomhole Pressure Intermittent Reducing Tool, China National Petroleum Corporation

- Dual-chamfer premium PDC cutter technology, Baker Hughes

- Frigstad D90™ semisubmersible rig, Frigstad Engineering Ltd.

- PowerDrive Orbit rotary steerable system, Schlumberger

- RipTide® RatHole Killer drilling reamer, Weatherford

- XBAT™ Azimuthal Sonic and Ultrasonic LWD Service, Halliburton

BEST EXPLORATION TECHNOLOGY

This award is given for the leading acquisition technology (including seismic, geochemistry and remote sensing) or algorithm/processing technology introduced during the previous year.

Winner: Coreflow digital rock and fluid analytics services, Schlumberger

This service develops rock models that distinguish pores from grains. Tests can be performed in digital simulations, in significantly shorter time. The CoreFlow service is technologically advanced beyond other digital core analysis services in the industry. Unique features allow its use for scenario planning, to improve efficiency in operations. Impact is immediate and worldwide. In the CoreFlow system, both digital and physical laboratory tests are included in a holistic approach to reservoir analysis. Physical core analysis is well understood and widely used by the industry, but the tests can take a long time to complete. The same types of tests can be performed, in digital simulations, in hours rather than days, or days rather than weeks. This allows for a wide variety of scenarios to be evaluated, in parallel with a few laboratory tests.

Finalists:

- Electro-Trac EM MWD technology, GE Oil & Gas

- MagTrak™ LWD magnetic resonance service in 8.25-in. tool size, Baker Hughes

- Petro-phone, Saudi Aramco

- Towed Streamer EM, PGS

HEALTH, SAFETY, ENVIROMENT/SUSTAINABLE DEVELOPMENT– OFFSHORE

This award is presented to a company that has made significant strides in protecting and enhancing the offshore environment where it operates. Whether through technical innovations, implementation of new standards or processes, or introduction of social and economic development efforts, the winner will have a program that made a marked improvement in an HSE/sustainable development endeavor.

Winner: HEADS (Hydrocarbon Early and Automatic Detection System), Repsol

The world’s first, fully automated, oil spill detection system consists of three elements: infrared cameras scan the sea areas continuously for 20 to 60 sec; detection radar scans the water for echoed anomalies, with each scan taking 3 sec; and two control algorithms detect the oil spill and set off an alarm while integrating the signals of both sensors and, based on these signals and the weather conditions, deciding whether to set off the alarm to signal an oil spill. HEADS is groundbreaking, because it is fully automated, works 24/7 and has 90% effectiveness. This technology addresses a problem, spills, that can quickly cause large-scale environmental damage unless detected and remedied early. There is also the potential saving of billions of dollars in compensation and cleanup costs for companies. Based on the combination of technology and groundbreaking algorithms, it can detect even the smallest of oil spills (10 liters). No other system exists that combines multiple sensors of different technologies with algorithms and an automated response. This tool maximizes the probability of detection and minimizes the probability of false alarms. The HEADS’ 90% spill detection rate compares to an average of 65% for existing systems. The associated computer has artificial intelligence, giving it the ability to teach itself while monitoring for spills, increasing its effectiveness over time. The first stage of the project contemplates surface application, but work is already underway to deploy the system for subsea applications, and also on the development of a fully automated response deployment. HEADS is modular and scalable, and can be adapted to any typology using different combinations of thermal and radar sensors.

Finalists:

- Acid-blending system, Baker Hughes

- Addressable Downhole Switch (ADS), GE Oil & Gas

- Environmentally Distinctive Well Test Burner, Halliburton

HEALTH, SAFETY, ENVIROMENT/SUSTAINABLE DEVELOPMENT– ONSHORE

This award is presented to a company that has made significant strides in protecting and enhancing the onshore environment and communities where it operates. Whether through technical innovations, implementation of new standards and processes, or introduction of social and economic development efforts, the winner will have a program that made a marked improvement in an HSE/sustainable development endeavor.

Winner: Bifuel hydraulic fracturing service for line gas, Baker Hughes

The diesel fuel that has powered high-horsepower hydraulic fracturing for decades generates air emissions, and adds to safety risks and potential non-productive time, because of the complexities of transportation and refueling operations. With the introduction of the first hybrid, bi-fuel pumps for hydraulic fracturing, Baker Hughes is leading a shift to the use of natural gas in fracturing. This not only reduces the environmental footprint of these jobs, but also improves operational efficiency, lowers costs, reduces safety risks, and capitalizes on the availability of North America’s abundant natural gas production supplies. The Bifuel service effectively substitutes cleaner-burning natural gas for a significant percentage of diesel in a retrofitted diesel engine. The bi-fuel-powered frac pumps meet all U.S. Environmental Protection Agency emissions standards and reduce nitrogen oxides, carbon monoxide, particulate matter and other emissions. The Bifuel service also offers the possibility of reducing flaring activities on the job site, since it can use field gas as a source of power. At a 50% substitution rate, the Baker Hughes Rhino Bifuel pumps can operate twice as long as engines running solely on diesel, and can nearly eliminate hot fueling, which minimizes risks for spills. Baker Hughes converted its first hydraulic fracturing units to bi-fuel status during fall 2012, to conduct one of the first bi-fuel pumping jobs in the Eagle Ford shale on a well using LNG.

Finalists:

- Distributed Acoustic Sensing (DAS) for hydraulic fracture monitoring, OptaSense

- Wireless remote fracturing operations, Baker Hughes

BEST OUTREACH PROGRAM

This award spotlights a program that has done the best job of teaching the general community, and younger generation, about the value of the oil and gas industry, which is often one of the greatest challenges confronting the sector.

Winner: Geoscientists Without Borders, Society of Exploration Geophysicists

SEG’s Geoscientists Without Borders® (GWB) program funds the application of geoscience technology around the world for real humanitarian benefits using technology developed by the oil and gas industry. Communities, and their leaders, who have never heard of geophysics, geology or petroleum engineering, learn that energy industry technologies can make a meaningful improvement to their day-to-day lives. In India, a project gave the community the tools and education to manage water through a drought season, allowing for a third crop, annually, to thrive. Leaders in Kingston, Jamaica, were prompted to plan for an emergency airport after project results demonstrated the city would be cut off from disaster relief via the current airport, after a significant earthquake. In South Africa, GWB investigated aquifers and the effect of invasive alien trees believed to be depleting a shallow groundwater aquifer, at a school for children at risk. Photo courtesy of SEG’s GWB.

Finalists:

- Aramco iExplore: Energy, Saudi Aramco

- EMSI High-Octane Tech Fest, Weatherford

- Environmentally Friendly Drilling Virtual Site, Houston Advanced Research Center

- Veterans Resource Group, Baker Hughes

BEST PRODUCTION CHEMICALS

This award is given to a company whose innovative stimulation or treatment chemicals have enhanced the production of oil and gas.

Winner: Sorb™ Ultra family of solid specialty chemicals,

Baker Hughes

Chemical treatments are matched to the specific reservoir and well environments, to inhibit downhole deposition. Sorb Ultra treatments can delay and, in some cases, eliminate the need for expensive deepwater interventions. The treatments also can help avoid weeks or months of delayed production, while waiting for the proper remediation treatment to be identified and applied. Sorb Ultra chemistry is applied as part of the well stimulation, to protect the near-wellbore environment (gravel pack) or the near-wellbore area and formation (frac pack and fracture). It functions as an intermediate strength proppant, with no negative impact on conductivity. The solid is added to the fluid at a specified ratio to the proppant to provide maximum protection, based on the well’s downhole environment and the application’s specific requirements. Its specially engineered, high-strength substrate ensures that a reliable application can withstand 16,000 psi at 20% loading.

Finalists:

- High Molecular Weight Hydrocarbons Removal, BCI Chemical Corporation Sdn Bhd

- SCALEGUARD, CARBO

- SolidClenz - Solid Deposition Treatment Technology, PETRONAS

BEST PRODUCTION TECHNOLOGY

This award recognizes a newly introduced production program, solution or fluid utilized during the year that allowed an operator to effectively manage and maximize production.

Winner: FLEXlift Curve™ tight-radius system, Baker Hughes

This system allows operators to reliably pass an ESP through high buildup rates of 15°/100 ft or more. Artificial lift system applications are limited by the buildup rates in deviated and horizontal wellbores. Wellbore deviations greater than 6°/100 ft often prevent the installation of ESP systems due to reliability concerns from the mechanical stresses placed on the flange connections between the system components. The system uses boltless connections in the equipment string to connect the pump, motor, seal and pump intake. These connections replace all the bolted flanges previously used between system components. Since the design of this new connection does not require bolts between system components during installation, overall installation time is reduced. During traditional equipment installations, bolts or tooling can be dropped downhole. If this happens, operations must stop to remove installed equipment, and to fish the dropped tools and/or bolts out of the wellbore. This increases downtime, deferred production, and rig costs.

Finalists:

- All-electric intelligent well system, Baker Hughes

- CENtigrade™ ESP production systems for thermal recovery

applications up to 527°F (275°C) bottomhole temperature, Baker Hughes

- PIPESIM steady-state multiphase flow simulator, Schlumberger

- RESMAN Flush Out™ model for zonal inflow quantification, RESMAN

- SandStim Chelant-Based Stimulation Service, Halliburton

- Slim Hybrid Tandem Tractor, Saudi Aramco and Welltec

BEST VISUALIZATION AND COLLABORATION

This award recognizes the data visualization, storage, software or manipulation solution that shows the greatest promise in enabling operators to achieve and create a real-time collaborative environment with potential for a step-change in operating efficiency.

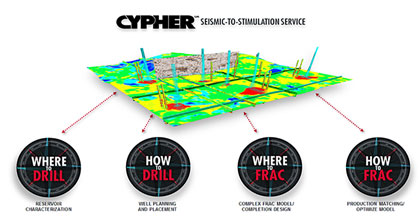

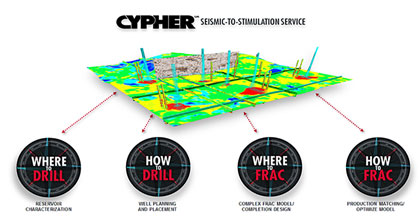

Winner: CYPHERSM Seismic to Stimulation Service, Halliburton

CYPHER service accelerates the learning curve for planning, drilling and completing wells. The CYPHER service creates an environment to identify key reservoir attributes, to help ensure the best wells are drilled first, and to maximize asset value and field economics. In one case study in the Barnett shale, Halliburton provided insight on “how to drill” with geosteering to best follow the plan and place the well in the proper zone after determining “where to drill.” Then, collaboration began on a completions design strategy to determine “where to frac” and “how to frac.” Using Halliburton’s CYPHER Software Suite, several changes were made in a systematic approach to leverage existing natural fractures and improve wellbore connectivity to the fracture system. The overall result was a more than 50% increase in production and cost savings through rate and horsepower reduction enabled by the new frac design.

Finalists:

- BEACON™ trusted operations service, Baker Hughes

- CemVision™ advanced fluid displacement simulator, Baker Hughes

- InQuest TubeMove™ 3.0, cased-hole completion modeling software, Baker Hughes

- iQx™ software, AGR

- SWRP-Multimedia Collaboration Platform, Subsea Well Response Project

BEST WELL INTERVENTION

This award is for advances in well maintenance, which can represent the highest expenditure over the life of the well. This award recognizes new intervention technologies that help make significant improvements in terms of time saved, costs reduced or production improved.

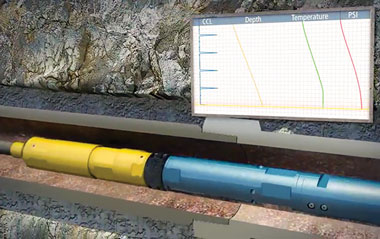

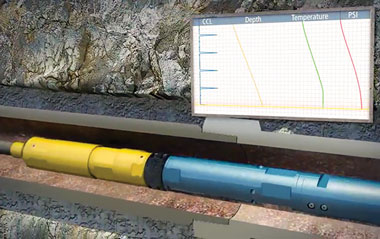

Winner: 2 1/8-in. TeleCoil™ intelligent coiled tubing service,

Baker Hughes

The Baker Hughes TeleCoil intelligent coiled tubing (CT) service combines real-time downhole data acquisition with the capability to simultaneously provide downhole power, significantly improving efficiency, and accelerating well recovery in all types of CT operations. From milling, stimulation, and well cleanouts, to gas lifting, camera services and logging operations, the TeleCoil service provides accurate, real-time downhole monitoring of depth correlation, differential pressure, and temperature. Since its introduction in the field, TeleCoil has been successfully deployed for numerous operations, including removing complex fish and improving acid stimulation. A high-production well on the offshore Norwegian Continental Shelf had been shut in for two years because of a lost fish across the perforated interval. Baker Hughes’ TeleCoil with camera and fishing tools provided real-time camera services, and differential pressure, temperature, and depth correlations. TeleCoil services enabled successful CT fishing, returning the well to production, cleaned the debris from the producing interval, and facilitated decision-making by providing real-time data and images to onshore staff.

Finalists:

- CutMaster X3 hydraulic multicycle pipe cutter, Schlumberger

- Halliburton Memory Pack (HMP) Tool, Halliburton

- Harpoon™ cut-and-pull spear, Baker Hughes

- NCS Closable Frac Sleeves, NCS Energy Services

INNOVATIVE THINKER

This award honors an individual who has demonstrated thought leadership in the upstream oil and gas sector. The winner will be an inspiration to all and a champion of the industry, not only in terms of the breadth of achievements, but also through the demonstration of vision and innovative thinking.

Winner: Billy Brown, Blackhawk Specialty Tools, LLC

Brown is the founder of Blackhawk, which adapted offshore technology in a slowed post-Macondo environment for onshore purposes. The company introduced a more compact cement head that allowed operators to rotate surface and production casing in cementing operations. Shifting the focus from offshore to the U.S. shale plays, Brown made Blackhawk both operational and profitable in the Marcellus within three months. Then, Blackhawk expanded to the Permian basin, and to the Eagle Ford and Niobrara shale plays. In 2011, Brown brought Blackhawk back to the Gulf of Mexico and launched the Deepwater Centralizer Sub, which helps companies achieve a more effective, efficient and exact primary cementing operation. Now, six years after the company’s inception, Brown has grown Blackhawk from 50 to 275 employees, with operating bases across the U.S. and overseas, all while remaining passionate in his pursuit to continually deliver highly engineered innovations that advance the oil and gas industry. Brown mixed innovative ideas with the best people in the industry and gave them the freedom and encouragement to expand upon those ideas. As a result of Brown’s leadership, Blackhawk pioneers technologically advanced tools that enhance safety, improve cementing operations and reduce rig time, saving companies up to $1 million per day.

Finalists:

- Chanchal Dass, Dass Oilfield Technologies Private Limited

- Dr. Eng Mohammed Darsi Abdulrahman Nedham, Petroleum Exploration and Production Authority, Yemen

- Blake Scott, Scott Environmental Services Inc.

- Nikolay P. Zapivalov, Institute of Petroleum Geology and Geophysics of the SB RAS

LIFETIME ACHIEVEMENT

This award honors an individual, who has made significant strides, and impacted the oil and gas industry throughout his or her career. The recipient may be retired from the industry, but will be an individual whose legacy still has an impact. [Nominee must be living].

Winner: John Quirein, Halliburton

A NASA physicist who became an oil-industry expert and thought leader, Quirein focused his lengthy career on integrated interpretation and software development, with an emphasis on gas shale petrophysics, geochemical log interpretation, geomechanics, and multimineral solvers. Throughout his career, he has been a prolific presenter at annual symposia, workshops, meetings, and topical conferences. He literally “wrote the book” on many technical advances in classical petrophysical areas, such as multi-component induction interpretation and software, mathematical petrophysics and multi-mineral solvers, image interpretation software, and neural networks. More recently, he has pushed the development of unconventional reservoir interpretation and software, geomechanical log interpretation, and dielectric log interpretation and software. Quirein has a strong business acumen and is keenly aware of the commercial competitive landscape, which makes him a sought-after speaker and teacher. His great technical breadth and energy are given freely to clients, colleagues, and young professionals. He received a PhD in mathematics from the University of Houston and worked two years with NASA before turning his focus to the oil and gas industry. He worked 10 years for Schlumberger, 12 years for Mobil, and for the past 14 years with Halliburton. At the latter, he helped position the company as an industry leader in the evaluation of unconventional resource plays. John has reached the highest distinction within Halliburton as the Halliburton Fellow of Petrophysics, where his talent and expertise are put to work in research and development of new products and services. He has authored or coauthored over 35 technical papers. He is a past president of the Society of Petrophysicists and Well Log Analysts (SPWLA), past president of the SPWLA Foundation, was instrumental in the formation of the High-Angle and Horizontal (HA/HZ) Special Interest Group within the organization, and was the recipient of the SPWLA Distinguished Service Award in 2012. Quirein holds nine patents, mainly in the area of neural networks.

Finalists:

- Saad AlDriweesh, Saudi Aramco

- Glen Benge, Senior Advisor, Cementing, Baker Hughes

- David Freeze, GE Oil & Gas

NEW HORIZONS

The winner of this award is a company with a game-changing product, technology or idea that redefines the industry’s thinking. The winner of this award symbolizes how the industry will operate in the future and will serve as a guidepost to the next generation of leadership entering today’s upstream energy sector.

Winner: Wave Glider®autonomous marine vehicle, Liquid Robotics Oil and Gas, a joint venture with Schlumberger

The Wave Glider is the world’s first fuel-free autonomous marine vehicle that harnesses kinetic energy from wave action in the ocean to produce locomotive propulsion. The two-part platform consists of a float that rides on the sea surface and a sub suspended 23 ft beneath the surface. It includes navigational and control systems, as well as electronics that support communications from an operations center via satellite. The vehicles are completely self-sustaining, using solar panels on the float to power all electronics. To move through the water, wave action lifts the float, causing the tethered sub to rise. This presses articulated wings on the sub down, creating a forward motion that drags the float along. As the wave subsides, the float descends, and the articulated lattices in the sub open again, propelling the float forward. The dual forward action is similar to the up and down kinematics that propel sea creatures along. With an included GPS system, the Wave Glider always knows where it is, and the course it must set to get where it is going. The versatile Wave Gliders were used in data acquisition and analysis undertaken for the Wheatstone Liquefied Natural Gas (LNG) project offshore Northwest Australia. Two gliders were used to perform a baseline survey, prior to commencing downstream and upstream pipeline dredging work for the construction of two LNG trains and a domestic gas plant.

Finalists:

- Application Specific Integrated Circuit (ASIC) design for HP/HT application, Baker Hughes

- Magnetic Nanomappers, Saudi Aramco

- Neftex Earth Model, Halliburton Landmark Software & Services

- Power to Lift system, GE Oil & Gas

- The TDX-1500 Top Drive, National Oilwell Varco

- Unconventional ROC workflow for reservoir-optimized completions, Schlumberger

|