|

ALI DANESHY, Shale Technology Editor

Last year, my article about provocative fracturing brought several reader feedbacks and requests for more similar thoughts. Encouraged by the response, in this article, I will bring up another topic that has made me scratch my head for some time. Specifically, is the way we complete our horizontal wells best for long-term productivity of our oil reservoirs? Is today’s pervasive horizontal well fracturing theory that we are creating a complex transverse fracture network ideal for getting the most oil out of our reservoirs? More to the point, is a complex transverse fracture network what we actually create underground and does it conform to our past experience with hydraulic fracturing? If it is correct, then are we running the risk of jeopardizing long-term production in the haste to get the best initial production? More to the point, does this fit our long-term experience with hydraulic fracturing?

BACKGROUND

Most of our production technology legacy is based on vertical wells. Location of these wells, and spacing between them, was approved by regulatory agencies and based on an assigned drainage area with further limitations imposed by lease boundaries, existing surface installations, etc. In many of the low-permeability reservoirs, these wells were fractured immediately after drilling, often without any attempt to produce them before fracturing. Often, vertical wells were sufficiently spaced away from each other that when selecting well locations, there was very little or no consideration given to fracture orientation and possibility of production interference between wells. The theory of hydraulic fracturing postulated that they are created by tensile failure of the borehole and the formation; that created fractures are perpendicular to the least in-situ principal stress, and that principal stresses are regional and their orientation and magnitude does not change from well to well. Thus, vertical fractures created in adjacent wells would be parallel and will not intersect each other. The fact that we very seldom encountered direct communication between vertical fractured wells reinforced the theory. Other evidence in support of this general theory was the relatively constant frac gradient measured in different wells in the same formation and depth.

|

| Fig. 1. Water flooding in vertical wells. |

|

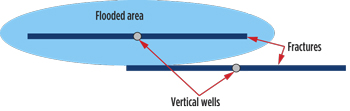

Enhanced recovery processes were developed and deployed to extend the productive life of the reservoir beyond fracturing and to increase the percentage of recovered oil. These included water, and various forms of miscible and immiscible flooding. Today, these processes are extensively used by the industry to increase reservoir productivity. Almost all oil reservoirs will eventually utilize some form of enhanced recovery operation. In the past, it was usually during this stage that attention was paid to questions related to production interference caused by fracture orientation. The manifestation of this interference was early water or polymer break-through. However, by this time, all wells and their fractures were in place and there were very few options available to change the production scheme. Also, in vast majority of cases, water break-through was not immediate and occurred after some time. This was interpreted to indicate that the created fractures were not directly intersecting each other or nearby wells, and that early water or polymer break-through was caused mainly by narrow spacing between the wellbore/fracture systems present in these wells, and/or through existing natural fracture systems, Fig. 1. In fact, these wells continued economical production long after the first break-through occurrence, albeit with high and increasing water cuts.

VALUE OF COMPLEX FRACTURE NETWORKS

The widespread use of horizontal wells for production of oil and gas from very marginal reservoirs has had unexpected consequences and results. For one thing, from experience we have found that best production results occur when the created fractures are perpendicular to horizontal well direction (transverse fractures). We deploy advanced fracture mapping techniques, such as microseismic or tiltmeter surveys, to determine the prevailing regional fracture orientation and then drill the horizontal wells perpendicular to this direction. Furthermore, in the urge for more early production, the spacing between these fractures is much closer than between fractures created in vertical wells. The spacing between the horizontal wells themselves has also been gradually decreasing. One consequence of the combination has been the dramatic rise in the occurrence of direct communication between offset wells during fracturing operations. Indications of these intersections have occurred while drilling, fracturing, and even during production. For example, fracturing fluid and proppant was recovered while drilling a well more than 2,000 ft away from an offset well that was being fractured at the time. Direct communication has been observed between offset wells 3,000 ft away, resulting in recovery of liquid tracers injected with the frac fluid from the offset well. Frac fluid invasion into the offset gas wells has resulted in flooding of the offset well and temporary loss of production until the frac fluid was lifted out. While some of the communication has been temporary and ended soon after the end of fracturing, in other instances it has been permanent and causing direct cross-flow between wells. In response to severity of this problem, many operators have adopted internal policies to mitigate the negative effect of direct communication, mostly by shutting offset wells during fracturing operations. In Canada, under the leadership of ERCB, a panel of industry experts has prepared recommendations for avoiding the negative impact of communication between wells. Their recommended steps include shutting the offset wells and informing nearby operators whenever attempting a fracturing treatment.

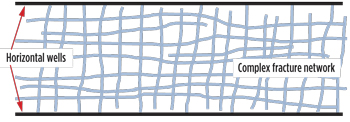

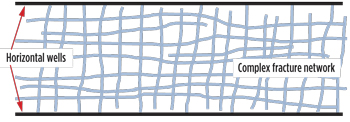

One of the very intriguing aspects of production from fractured horizontal wells has been their high initial rates, beyond what would be predicted for such low-permeability reservoirs. Most experts believe permeabilities of these shale formations are extremely low, in the micro- or nano-Darcy range. This permeability range does not match gas flow rates in the range of several MMscfd or oil flow rates of several hundred bopd or higher. The expert explanation for the higher flow rates is that these formations contain natural fractures that are then linked with each other by the hydraulic fractures, thus creating a complex network of inter-connected fractures, Fig. 2.

|

| Fig. 2. Complex transverse fracture network. |

|

What strengthens this belief is microseismic mapping that suggests crisscrossing fractures spread over a large area covered by the horizontal well. The resulting system is defined as “complex fracture network” and has been the subject of many technical papers. Several studies have attempted to further define the flow properties of this complex fracture network through simulation and history matching. Some view the creation of complex fracture network as very desirable and some service companies have specific products and processes that claim to increase the intensity and complexity of fracture networks.

PRODUCTION CONSEQUENCES

Regardless of how the complex fracture network is formed, its presence has important production consequences. First, it will result in high initial production, beyond what would be expected from matrix flow alone, followed by rapid production decline. (Presence of complex fracture network does enhance the initial productivity of the reservoir, but it is not the only system that can do this). But beyond this stage, and when one needs to explore flooding operations, the presence of this complex network between two offset wellbores can interfere with effective sweep of the oil remaining in place. The injected fluid can easily move between the two wells through the existing fracture network. The effect of fluid flow in the fracture network surrounding the formation blocks will be to compress the fluid inside them, rather than pushing it out. The net effect could be very inefficient flooding operations and very low total recovery percentages. Thus, once we move beyond the initial production phase and into any kind of flooding operation, the presence of a complex fracture network can be detrimental to productivity and production health of the reservoir.

Other factors that can further complicate the flow picture are:

- The type of completion, whether open hole with liner or cased and cemented liner. The open-hole option makes it very difficult to selectively direct the fluid through the long horizontal section. New downhole tools will be needed to close some of the flow channels and redirect the fluid through a more desirable path.

- Downhole tool reliability, especially for completions using packers with open-hole liner. Failure of downhole tools will jeopardize our ability to control injected fluid distribution within the horizontal well.

- Number of fracture stages. Larger number of fracture stages, and shorter spacing between them, makes it more difficult to redirect the injected fluid within the reservoir.

- Spacing between wellbores. The shorter spacing between wellbores reduces the length of flow path and accelerates early break-through.

- With the complex fracture network extending between the two wells, in-fill drilling between the two wells is not a viable option

The above discussion brings up a very serious question; “Are we jeopardizing the long term productivity of our reservoirs by excessive focus on short term results?” If one were to accept the presence of the complex fracture network as being real and representative of the actual fracture behavior, then the answer will have to be a clear “yes”.

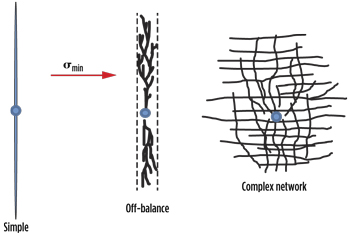

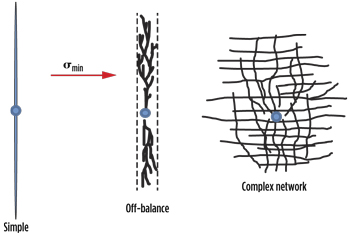

I have spent almost all my professional career studying and trying to understand the technology of hydraulic fracturing. Over the years, I have been exposed to many concepts and ideas (some of them my own) that, while true for a time, did not survive the tough questions that come with time and closer scrutiny. For example, the idea of an ideal single tensile fracture was challenged by tests at Nevada Test Site and by the MWX experiments in the 1980s. I offered the concept of “off-balance” fracture growth in response to these observations. Off-balance fractures satisfy the requirement that the overall direction of the fracture would be perpendicular to the least in-situ principal stress, but extend it to include the influence of formation heterogeneity, well completion, and presence of natural fractures. My general attitude towards the many fracturing theories being offered these days is to try to keep an open, but skeptical mind.

FRACTURE GROWTH THEORIES

The three main theories of fracture growth pattern under discussion these days are presented in Fig. 3. Assuming a constant injected volume, one can intuitively see that assuming a simple fracture will yield the longest hydraulic fracture. Production from simple fractures is not expected to have the rapid decline we observe in horizontal wells. Off-balance fracture will be shorter because of the presence of branches, and higher surface area that increases the leak-off volume. The larger surface area of off-balance fractures can create the early production surge followed by rapid decline that we observe in horizontal wells. The complex network pattern should result in substantially shorter fracture because it is spread more laterally, and it has much larger surface area for leak-off. Thus, in order to justify the long fractures that are required for communication between wellbores, one has to assume that these are inter-connected within the formation and form a single complex fracture network. In order for this to happen, one has to accept that these fractures are growing in multiple crisscrossing directions. To accept this, we have to assume that maybe at least the two horizontal principal stresses are equal or very close to each other (with a difference of less than a few hundred psi). While this may be true in some limited occasions, there is plenty of evidence that contradicts its universal occurrence.

|

| Fig. 3. Existing theories of fracture propagation pattern. |

|

The geological structure of earth conforms to the unequal stress model. Under equal horizontal stress regime, the influence of natural fractures will be much prominent and we should have seen many more incidents of fracture intersection in vertical wells. In reality, the incidents of communication between vertical fractured wells have been extremely rare. Experiments with fracturing of naturally fractured formations with unequal stresses do not support wide fracture scatter. The exceptionally high frequency of wellbore-to-wellbore communication is mainly limited to horizontal wells. Furthermore, wellbore-to-wellbore communication occurs even in treatments where injected volumes are quite low, such as many of the treatments that are performed in Canadian oilfields such as the Bakken, Viking, etc. Another contradiction is that communication is not continuous. It begins some time after start of injection, and then ends before the end of all stages. This suggests that all fracturing stages are not interconnected.

In light of the above contradictions, how do we explain the agreement between a complex network fracture pattern with microseismic mapping and numerical reservoir simulations? In the case of microseismic, it is generally recognized that this technique detects presence of events occurring within the fracture itself, as well as other events triggered by the fracture, but not directly connected to its main body. By assuming that all events during a microseismic survey are connected with the main fracture body, we may be stretching the interpretation beyond validity point. But even with scattered data, microseismic mapping has been successful for determination of a dominant fracture orientation, which then contradicts the assumption of equal horizontal stresses. The case for production history matching is much easier to explain. Numerical simulation does not provide a unique solution to matching the production history. Therefore, the simulation results offer a possible, but not necessarily the only fracture pattern that can match the production.

RETHINKING COMPLETIONS

By the above discussion, it is not my intention to completely contradict the idea of a complex fracture network. Rather, I am simply cautioning the industry against accepting this model without raising legitimate questions about its validity, as I have done in this article. The stakes are too high and industry has many good reasons why it should make a serious effort to find what is the correct fracture growth pattern. If the complex fracture network pattern is truly what is happening, then, in my view, a quick re-thinking of our completion practices is in order. If the actual growth pattern is off-balance, then the problem is not as severe and one should be able to get sweep efficiencies similar to what we have experienced with vertical wells by selectively directing the injected fluid within the horizontal well. However, we will still be faced with the real problems caused by direct communication between wellbores, which is triggered by our emphasis on creating transverse fractures. The challenges we are facing have two main components: how is the fracture growing within the formation, and, how do we reduce or eliminate the occurrence of wellbore to wellbore communication. The problem of fracture communication can be solved relatively easily. For example, and as an alternative, it may be more suitable for us to opt for longitudinal/axial fractures instead of present emphasis on creating transverse fractures. Because of the wellbore influence axial fractures will have lower tendency to scatter within the reservoir. If we are truly creating a complex fracture network, then one option would be to increase the spacing between fracture stages such that they do not interconnect. This gives us a chance to at least sweep some of the oil from the un-fractured parts. The definition of recoverable reserves will also need to be changed to reflect the oil which is accessible for flooding operations.

CORING FOR FRACTURE RESEARCH

Our existing horizontal well operations have given us a simple and quick way to determine the fracture growth pattern. For example, this can be done by drilling and coring of a horizontal well between two communicating offset wells and parallel with them. The recovered core will show us where the fractures are, their separation and whether they contain any proppant. In fact, by selective use of proppant tracers, we will be able to track the movement of the proppant inside the fracture network. This simple experiment will give us a wealth of data very useful for optimizing our completion system and maximizing our recoverable reserves. More exotic completions using fiber optics and acoustic sensors will allow us to map the flow of fluid between the wellbores. This type of research by the industry is urgently needed if we are to optimize the oil recovery from our unconventional reservoirs and deliver the volumes that the public is expecting from us.  |