High oil prices and declining reserves of light crude are serving as the incentive to extract as much oil from existing reservoirs as possible. In addition, there are renewed efforts, and considerable focus, on adapting recovery techniques to the production of heavy oil. In mature fields, enhanced oil recovery (EOR) techniques, such as carbon dioxide injection, waterflooding, polymer flooding, chemical treatment and gas lift, have increased production from older formations and are seeing success in heavy oil recovery.

The life of an oil well goes through three distinct phases, where various techniques are employed to maintain crude production at maximum levels. The three stages include:

• Primary recovery, in which the oil is forced out of the reservoir and

into the wellbore by pressure generated from gas present in the oil

• Secondary recovery, in which the reservoir is subjected to

waterflooding or gas injection to maintain a pressure that continues to

move oil through the wellbore to the surface

• Tertiary recovery, also known as EOR, in which oil flow is improved

by use of fluids that reduce oil viscosity. These fluids could consist of

gases that are miscible with oil (typically carbon dioxide), steam, air

or oxygen, polymer solutions, gels, and surfactant-polymer

formulations.

Typically, primary recovery provides access to only a small fraction of a reservoir’s total oil capacity, while secondary recovery techniques can increase productivity to a third or more of the oil in place. However, tertiary recovery enables producers to extract up to 50% or more of a reservoir’s original oil content, depending on the reservoir and the EOR process applied. In fact, the worldwide importance of heavy oil will continue to emerge, as the price of oil remains high and the demand for it remains strong.

Obstacles to recovering billions of barrels of residual oil and heavy oil are economic, technical and regulatory/legal. Economic barriers are daunting. For a full-scale project, a great deal of money must be spent to re-drill and rework producing and injection wells, and new corrosion-resistant flowlines must be installed. Millions of dollars are spent up front with a long-term, unpredictable stream of revenue to pay off the investment.

Many countries in the world have heavy oil reservoirs, particularly Canada and Venezuela. Rising energy demands coupled with a decline in conventional oil reserves, have led to increased interest in heavy oil recovery in recent years. The size of these heavy oil deposits is immense, and these are likely one of the primary, future energy sources in the years to come. Unfortunately, oil in these reservoirs is highly viscous, and cannot easily flow to production wells under normal reservoir conditions. Understanding the mechanisms by which heavy oil can be displaced in reservoirs is crucial to its successful recovery.

It is not surprising that there has been a growing interest and research in the potential to expand EOR methods to heavy oil reservoirs. In fact, during the past five decades, a variety of EOR methods have been developed and applied to mature, mostly depleted oil reservoirs. Overall, EOR development has expanded successfully into heavy oil recovery, and some projects offer additional benefits, such as sites for disposing (sequestering) carbon dioxide at modest costs or even full-cycle profit.

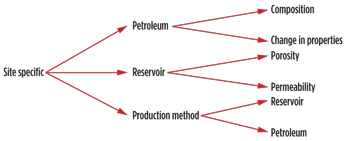

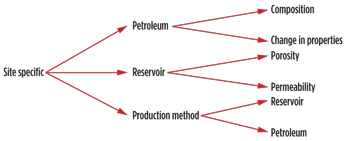

However, whatever the method, oil recovery is dependent upon several factors, the most prominent of which are oil properties, reservoir properties and production methods. The site specificity cannot be overemphasized and must be given serious attention, Fig. 1.

|

| Fig. 1. Oil recovery is site-specific and dependent upon properties of the oil, properties of the reservoir, and the production method applied. |

|

The objective of this supplement to World Oil is to present to the reader the current methods of recovery. In addition, the breadth of the articles gives an indication of the application of different methods to different reservoirs and different oils, thereby emphasizing the need to consider site specificity. This is accomplished through technical articles presenting case histories on topics such as:

• CO2 injection design, implementation and performance in the low-

pressure dolomite reservoirs.

• Continuous monitoring of an enhanced oil recovery project using time-

lapse seismic.

• Using intelligent well technologies to increase thermal enhanced oil

recovery.

• In addition, there are articles about new EOR technology submitted

by equipment/service companies.

Finally, it is essential to realize that in the current context of conventional petroleum and heavy oil, there are several parameters that can influence properties and recovery. Readers will find this supplement useful and informative as a means of defining and understanding these parameters.

|

The author

|

|

James G. Speight, Laramie, Wyoming. Dr. Speight is the author of Enhanced Recovery Methods for Heavy Oil and Tar Sands from Gulf Publishing. |

|