A digital platform for real-time operations in the High North

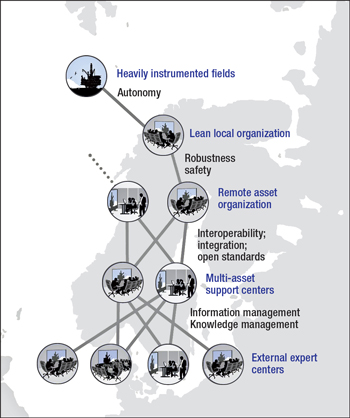

A joint industry project seeks to enable Arctic development through seamless collaboration across disciplinary, geographical and organizational boundaries.Frédéric Verhelst, Johan W. Klüwer and Torbjørn Skramstad, Det Norske Veritas; Frode Myren, IBM; Jens Ornæs, National Oilwell Varco; and Bård H. Tvedt, Epsis During a four-year period starting in May 2008, 23 companies are collaborating in the Integrated Operations in the High North Joint Industry Project to develop a digital platform for use in an Arctic setting. Operational models for these remote and sometimes hostile environments are often based on a lean local asset organization that is dependent on an extended support network. Open standards are needed to ensure interoperability, to facilitate integration and to transfer data. Integrated Operations apply shared information and knowledge models based on open standards to make collaborative work processes more efficient. THE ARCTIC REGION The Arctic region is experiencing high oil and gas activity levels. This is not surprising, since the region is expected to hold vast amounts of extractive energy resources. In a recent study, the US Geological Survey estimated that areas north of the Arctic Circle contain 90 billion barrels of undiscovered, technically recoverable oil and 44 billion bbl of natural gas liquids.1 Most of the Arctic resources lie offshore in environmentally very sensitive areas, beneath thick ice and/or in deep water. Weather conditions, and distance to existing infrastructure and centers of population, add additional operational and logistic challenges. To meet all requirements and at the same time maintain profitable operations, the industry needs to create new field development and operational concepts that include heavily instrumented facilities. These operational concepts will often be based on a lean local organization supported remotely by an extended support model. EXTENDED SUPPORT NETWORK While the first implementations of integrated operations were focused on a one-to-one connection between an operational site and a dedicated asset team, extended support networks have gradually been introduced, Fig. 1. Different operators are establishing lean local organizations, especially in distant and otherwise challenging locations such as the High North. A lean local organization will be able to offer basic support functions, but will rely on a remote asset organization for more advanced support. The support network may be extended further by the introduction of multi-asset support centers, which offer second- or third-line specialized services to several asset teams simultaneously.

Examples include centers for drilling or production support, for condition monitoring of heavy rotating machinery, and instruments for fiscal metering. These centers typically offer services that are not so common and that require special expertise, experience and, sometimes, tools. Alternatively, these multi-asset support centers may also offer services that may benefit from coordination across individual assets, such as planning and scheduling with relation to logistics and operations. By offering these services from a centralized entity, one may make more efficient use of t2he available resources. There are further benefits from these multi-asset support centers, as they are well suited to the transfer of knowledge and experience from senior to more junior experts. The extended support network may also involve external expert centers. This may be arranged on an ad-hoc basis, or because some support functions are outsourced to an external service provider. For example, the vendors of heavy rotating equipment may act as experts in a condition-based monitoring work process. COLLABORATION CHALLENGES These extended collaboration networks require an almost continuous interaction between the different locations. A platform for effective and efficient data and information exchange and decision making becomes mission critical in these networks. A robust and secure digital platform based on open standards is required, supporting a much higher degree of interoperability across multivendor applications, disciplines, geographic locations and organizations than is common today. There are four particular data and information challenges associated with collaboration across boundaries. The first challenge is to find relevant data and information in the huge volumes of real-time and historic data. This is the proverbial “needle in the haystack” problem. Multi-asset support centers have to handle data streams from a multitude of assets and need new tools and work processes to do this more efficiently and effectively. A second challenge is to understand the exact meaning of the data and information. Most often the full meaning of a set of data is not given in the data set itself. One needs to be familiar with details of the systems and processes that produced the data and information for a correct and reliable interpretation. Currently, the use of data and information is not seamless, but requires human interpretation and contextual understanding. The third challenge is that with an extended support network, the external experts and the experts from other disciplines give advice to a multitude of assets; i.e., they do not work full time on a single asset. Therefore, they do not always have an intimate and up-to-date knowledge of the detailed setup of a given part of the system, and for instance, will not always know in detail the topology of the system. A fourth challenge is to ensure that decisions arising from the work process are executed in a timely fashion. This is often a bottleneck, since it most often involves human interaction at the operational site for the decisions to be implemented. HIGH NORTH INTEGRATED OPERATIONS The goal for the Integrated Operations in the High North (IOHN) project is to solve the above challenges by designing, piloting and demonstrating a reliable and robust solution architecture and platform that will be able to facilitate collaboration across boundaries.2 Existing open standards are used and extended when required, and new standards are incubated to ensure interoperability, to facilitate integration and to transfer data. To make data-to-information-to-decisions work processes more efficient, information and knowledge models based on open standards are also used. The IOHN project is set up as six activities organized in a matrix; three related to the digital platform and three related to pilots for different business domains. Within these business domains, architectural relevant-use cases have been defined, which form the basis for extracting the requirements for the digital platform and are used later to test parts of the digital platform. The digital platform forms a natural foundation for the IOHN project. This platform follows the service-oriented architecture principles and provides an integration bus infrastructure. An integration information model (IIM) is a key part of the extended integration layer and compensates for the semantic information differences caused by local differences in meaning between the plant and the enterprise layers through a model-aware approach. This enables users to find contextual information by easily shifting down to lower levels of aggregation and, for instance, exploring individual measurement details, or by shifting up to higher levels of aggregation to see the dependencies of one given sub-system with other sub-systems. The measurement values and other data and information items are made available from authoritative sources such as a data historian. Respective adapters transform the data delivered by the applications “around” the integration platform into the IIM canonical view across the information bus such that applications connecting to the integration platform deliver and receive information in their specific data formats. Two additional activities have been set up to focus on aspects of the architecture of particular interest in this project. One activity is dedicated to applying open standards so that data and information may be used seamlessly across boundaries of data models, operational domains, enterprise layers, etc. The project is using, and extending, a reference data library, or ontology, based on resources managed by the standard custodians: the POSC Caesar Association and the International Organization for Standardization. This allows the project partners to provide content with unambiguous and explicitly defined interpretations. The activity contributes to the oil and gas ontology, built on the international standard ISO 15926, incorporating and applying existing domain standards. An additional activity focuses on specific safety and security aspects for highly interconnected and software-intensive systems. In conventional operations, the offshore control systems domain is shielded from the outside world, and only one-way traffic of data from offshore to onshore is allowed. In the future, a tighter connection may be required between the office and the control domain, and communication might even partly occur via secured internet. This will require that safety and security issues are taken into account from an early phase in the design, hence this activity within IOHN. Use cases within three different business domains are defined in the IOHN project. They were used early on to extract the requirements for the architecture, and are used to test and demonstrate the digital platform. The drilling and completion pilot focuses on seamless interoperability through open standards at the drilling control level. There is currently a gap in the cost-effective and timely utilization of all the real-time data available during drilling. Improvements will come from systems that are closing the loop—i.e., by automatically analyzing the real-time data stream, making decisions autonomously and directly intervening with the drilling control system. Such systems as may integrate with external service providers rely on a common, computer readable “understanding” of the drilling domain. This will lead to a better safeguarding of operational limits, less nonproductive time and, in the end, better and more efficient well placement. The reservoir and production pilot focuses on the detection of sand production and associated erosion management. Within the Arctic setting, the criticality of these risks only increases, and it is therefore crucial to have both trustworthy measurements of sand production volumes and reliable methodologies for erosion monitoring and predictions. One of the possibilities that arise from the digital platform is increased collaboration and interoperability. The pilot is exploring this opportunity by facilitating new work processes for an expert competence center supporting several assets with production-related issues. The operations and maintenance pilot focuses on condition-based maintenance and acts as an extension to both the drilling and the production pilot. For the drilling pilot, condition-based maintenance will interact with the decision-making process and help in safeguarding the operational limits of critical components of the drilling machinery. In the production pilot, this is a natural extension to erosion monitoring and management. PROJECT STATUS The IOHN project began in May 2008 with a planned duration of four years. Work is well underway on the digital platform and the different pilots. In 2010, the first proofs of concept for the different pilots have been delivered, along with work on different parts of the digital platform. The pilots defined for drilling, production and operations and maintenance will be used at later stages in the project to demonstrate the value of the platform. The project is also working on position papers on how semantic web technologies and autonomous systems may impact the current operational models. At this time, 23 companies and organizations from different parts of the value chain are participating in the project. These are (in alphabetical order): ABB, Business Association of Norwegian Knowledge and Technology Based Enterprises (Abelia), Baker Hughes, Cisco, Computas, Det Norske Veritas, Eni, Epsis, FMC, IBM, IO Centre, the International Research Institute of Stavanger, National Oilwell Varco, Norwegian Defence, the Norwegian Defence and Security Industries Association, the Norwegian Institute of Science and Technology, the Norwegian Oil Industry Association, the Petroleum Safety Authority Norway, the POSC Caesar Association, Siemens, Statoil, the University of Oslo and the University of Stavanger. Two sub-projects are also partly sponsored by the Research Council of Norway. The project is managed by Det Norske Veritas. Additional information about the project may be found on the IOHN-website: http://www.IOHN.org/. LITERATURE CITED 1 USGS, “Circum-Arctic resource appraisal: Estimates of undiscovered oil and gas north of the Arctic Circle,” 2008.

|

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)