Murray Roth, President, Transform Software and Services

Stretching from the meandering Rio Grande, the Eagle Ford Shale play extends along a 50-mile corridor in South Texas for over 400 miles to the northeast. Younger (geologically and with regard to development), deeper and hotter than other well-known shales like the Barnett, Marcellus, Woodford and Horn River, this “newly discovered” reservoir is garnering attention with impressive initial well production levels. Once considered only a source rock for shallower oil and gas formations, the Eagle Ford is emerging as a major gas, condensate and oil resource.

Working with E&P companies and their data across multiple shale formations, our company advocates an “unconventional interpretation” approach to developing these resources. This approach requires not only a new understanding of traditional reservoir properties like permeability, porosity, saturation and thickness, but also the inclusion of geomechanical, geochemical and other perspectives to incorporate measurements like rock strength, stresses, total organic carbon (TOC) and thermal maturity.

|

|

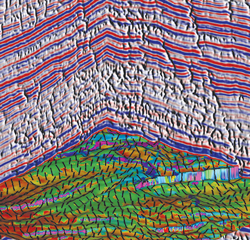

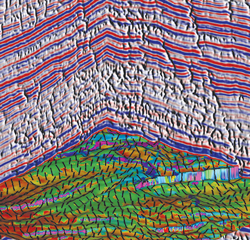

Fig. 1. Interpreted structural horizon draped with thickness and dip indicators. Backdrop of vertical seismic panels with fracture patterns. Courtesy of Global Geophysical Services.

|

|

A traditional reservoir property, permeability, is typically extremely low in shale, so effective production is often tied to finding existing fractures and creating new ones. A valuable well planning map often takes the form of lateral estimates of natural fracture densities and trends. In the Eagle Ford, 3D seismic attributes are used to map levels of natural fracturing (see figure). Azimuthal seismic attributes are commonly used to estimate velocity anisotropy (variation with direction), providing additional indicators of fracture orientations and density.

Ironically, shale is often the last type of lithology that operators want to find. Higher clay content, as found in typical shales, produces a more ductile nature that is not amenable to easy hydraulic fracturing. In the Eagle Ford, higher content of minerals like silica, calcite and carbonates can increase the rock’s “crackability.” Certain seismic attributes (e.g., lambda-rho and mu-rho) and derivatives are useful in producing volumetric estimates of relative rock strength and, thus, susceptibility to fracture creation.

Microseismic monitoring of hydraulic fracturing is becoming increasingly popular for estimating the stimulated rock volume and complexity of induced fractures. In this technique, individual fracturing events are detected and positioned using triangulation of special seismic records. In the Eagle Ford, we are seeing high-quality microseismic results, using lower-cost surface acquisition, as an alternative to traditional downhole measurements. This is leading to better quantification of stimulation effectiveness and calibration of 3D seismic indicators.

Another key in the Eagle Ford, also illustrated in the figure, is the extensive and complex faulting that can present hazards to both drilling and completion of horizontal wells. In some scenarios, faults can provide an unwanted conduit to thousands of gallons of frac fluid. Seismic data is invaluable for well planning, to avoid straddling highly faulted zones, and for driving accurate, real-time geosteering of wellbore paths to remain within formation.

Maps of estimated TOC and vitrinite reflectance are particularly diagnostic in the Eagle Ford, as indicators of the amount of hydrocarbons in place and the relative thermal maturity of the hydrocarbons (i.e., gas/condensate/oil). Increasingly, due to the per-Btu price disparity between oil and gas, the presence and productibility of non-gas resources can largely determine the profitability of individual wells.

A typical Eagle Ford “unconventional interpretation” project may contain on the order of 50 seismic volumes; 30 or so wells, with associated logs and geologic tops; multiple microseismic surveys; structural, geochemical and various attribute maps; and an array of production, drilling and completion engineering data. Crossplot and multivariate statistical analyses are used to comprehend the multitude of data types and scales, with the goal of constructing some form of sweet-spot map or volume. Integration of the spectrum of geophysical, geological and engineering data is driving optimization of well placement, orientation and completion parameters.

An emerging workflow uses microseismic data to estimate the amount of rock that is stimulated in individual fracture stages, entire wells and groups of wells. These measurements are calibrated with well and individual fracture zone production, as estimated using spinner logs. We anticipate that real-time acquisition and processing of microseismic data will emerge as a standard procedure in the Eagle Ford, providing the immediacy of well geosteering to the optimization of intra- and interstage frac operations.

We are also seeing a trend toward more integrated asset teams in shale plays, particularly in the Eagle Ford. Some reservoirs may be amenable to development as “shale gas factories” using an engineering-led pattern-drilling approach. However, the complexities of the Eagle Ford are demanding interdisciplinary teamwork with commensurate rewards of high initial production of gas, liquids and oil that, with luck, will transition to long-term, low-decline producing wells. Less than two years after the initial PetroHawk “discovery” well, the Eagle Ford has earned a spot as one of the most exciting and promising shale plays in the US.

|

THE AUTHORS

|

|

Murray Roth (murray@transformsw.com) is the president and co-founder of Transform Software and Services. Before starting Transform in 2004, he worked with Halliburton for 25 years. He holds a degree in astrophysics and physics from the University of Calgary.

|

|