A comparative evaluation of matrix acid systems was conducted in a high-clay reservoir for Petrobras.

Oscar J. Jaramillo and Ricardo Romero, Petrobras; Alexis Ortega, Art Milne and Manuel Lastre, Schlumberger

Many sandstone reservoirs are composed of more than 40% clay and feldspar. Common problems in these reservoirs include fines migration and poor response to conventional, hydrofluoric acid-based fluids that use organic and inorganic acids. Laboratory testing has revealed that the formulation of organic clay acid (OCA)—specifically concentrations of acids that make up the treatment fluid—can be customized for the mineralogy and temperature of the formation being treated. Customization improves treatment effectiveness, prevents future fines migration and, ultimately, sustains post-treatment production improvements over time.

Since 2003, customized OCA has been used as the main treating fluid in more than 120 applications to successfully treat a variety of reservoirs that had previously been considered untreatable or difficult to treat. These reservoirs ranged in temperature from 105 to 250°F.

This article describes a comparative evaluation of matrix acid treatment systems in a high-clay reservoir. The initial field trials compared conventional, hydrofluoric acid-based stimulation treatments from several different service companies in multiple wells in the same reservoir. Results from these conventional systems showed good initial increase in production rates; however, shortly after treatment, production rates declined rapidly.

In subsequent field trials, the customized OCA was tested in the same reservoir, which resulted in good initial post-treatment production improvements that were sustained for more than six months.

TREATING HIGH-CLAY FORMATIONS

One of the key challenges for treating high-clay formations is the need to remove or stabilize the mobile fines in the pore space without destabilizing the clays in the formation matrix or the formation itself. The critical formation matrix (the area around the wellbore where most of the pressure drop occurs) must be stimulated in such a way as to minimize undesired reactions of the treatment fluid with the formation, which can cause reaction products to precipitate in the matrix and additional production problems. Finally, low critical matrix velocities must be addressed because they can cause plugging while injecting treatments.

ACID SYSTEM

The new acid has a similar basic chemistry to that of a retarded hydrofluoric acid (HF). However, unlike retarded HF, the new fluid uses an organic acid as a chelant and is effectively a blend of organic and fluoroboric acid—thus, an organic clay acid.

The fluoroboric acid is generated by adding HF and boric acids to the main treatment fluid. Crucial to the OCA’s successful treatment is the initial concentration of free HF and the available HF from the hydrolysis of the fluoroboric acid with respect to the clay mineralogy and temperature of the particular formation being treated. The stimulation effect for a particular formation can be optimized and future fines migration prevented by adjusting the initial concentration and ratio of hydrofluoric and boric acid.

Acid formulations are optimized for both clay content and temperature using a geochemical simulator. The concentration of the organic acid (the chelant) is also adjusted based on an analysis of the effluent during core testing to minimize precipitation.

FIELD BACKGROUND AND MINEROLOGY

The field, located in southern Colombia, produces oil and gas from fluvial shaly sandstones of Early Miocene age. A typical well has several distinct sands, which may contain light or medium oil or mobile water. The main reservoir’s depositional environment is continental, with meandering shallow channels. The reservoirs are low-temperature (140°F), shaly sandstones composed mainly of quartz, feldspars, clays and lithic fragments, with porosity ranging 14–22%, which can decrease significantly due to cementation.

The field was first put on production in 1989. In 1999, water injection at the perimeter was started, followed by in-field water injection in 2004. Originally, the reservoir was considered to be unfractured; however, since beginning water injection, it appears that the reservoir has a complex system of fissures and high-conductivity channels. This fracture system is the reason for the large variation in the injection rates and pressures when treating these wells, and for the increased water production following some treatments. Some wells are in direct communication with one or more injection wells. In an attempt to compare effectiveness of different matrix treatments, the wet producers have been excluded from this study.

A thin-section study showed angular quartz grains of average size with an abundance of volcanic fragments and very little calcareous cement. Little diagenesis has occurred because of the low overburden, and the formation is friable. With no calcareous cement, the quartz grains are free. The matrix is highly porous (more than 20%) because of low compaction. In many cases, the primary and secondary (moldic) porosity is filled with chlorite, which has limited the deposition of other cementitious material. While porosity is high, permeability is generally low (1–20 mD). The combination of high porosity and low permeability is caused partly because calcium in the volcanic fragments (epidote, plagioclase, smectite and actinolite) has been leached out by the relatively fresh formation water and deposited as calcareous cement that plugs the pore throats.

X-ray diffraction measurements show that total clay and feldspar content ranges between 20 and 40%. The smectite clay volume is typically high enough for resistivity logs to respond more to clay volumes than to the differences between oil and water.

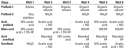

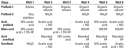

Table 1 shows the mineralogy of cores taken from several different sands in two wells in the field. The high concentration of smectite means change in salinity increases the risk of destabilizing the clay formation. The significant percentage of zeolite and chlorite means that the formation is hydrochloric acid (HCl) sensitive. The HCI reacts with these clays, even at low temperatures, which could destabilize the clays and create reaction products. When carbonate is present, it is considered to be the cementing material. Therefore, when acidizing, the risk of further deconsolidating an already friable formation exists, which can collapse the formation and is thought to have happened several times in the past in this reservoir.

| TABLE 1. Field mineralogy |

|

HF STIMULATION

The initial field trials sought: 1) to remove formation damage caused by scaling, organic deposits and fines; and 2) to prevent future fines migrations in the matrix. The scaling and fines migration are thought to be caused by in-field water injection and the organic deposits caused by declining reservoir pressure.

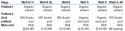

Table 2 shows the treatment design for each of the six wells that comprise the study, which represent different HF treatments from various service companies. The acid systems were selected based on core flow testing or by use of treatment design software. The treatment parameters used for the six treatments were as follows:

• Temperature: 120–140°F

• Permeability: 5–400 mD

• Porosity: 17–20%

• Water saturation: 40%

• Reservoir pressure: 800–1,500 psi

• Radial treatment: 3 ft

• Max. surface pressure: 2,000 psi

• Max. pump rate: 2 bbl/min.

| TABLE 2. HF treatment design |

|

Because of the number of producing sands and the need to ensure complete coverage, the treatments were performed in two stages using straddle packers.

HF results. Directly after these treatments, the average production per well nearly tripled, which was interpreted to mean that, in most cases, the damage was removed. However, results varied greatly for each well.

Production results for Wells 1 and 3 indicate that using a 10% acetic acid preflush is beneficial, primarily to remove the calcium carbonate, thereby preventing the HF from spending prematurely on the carbonate and possibly precipitating calcium fluoride. The treating pressure in Well 3 showed a marginal increase, which indicated insufficient acid volume or some incompatibility with the formation or formation fluids, whereas in Well 1 the pressure decreased.

For Wells 4 and 6, which had similar treatments, improved production is ascribed to the acetic acid and HCl preflush, as well as the HCl/HF. The pressure drop in Well 4 (800 psi), which indicated damage (fines) dissolution when injecting the acid, was significantly greater than the pressure drop in Well 1 (200 psi). The change (most commonly a decrease) in the treating pressure when injecting acid into the formation at a constant rate is a means of evaluating the effectiveness of the treatment in removing formation damage (skin). In Well 6, the extremely good response is thought to be, in part, from higher matrix permeability or fissures, as seen from a treatment pump rate of 4 bbl/min., higher than the normal to 2 bbl/min.

Though initial production rates increased, in some cases significantly, those production levels declined rapidly for all wells. In fact, within three months, all wells except for Well 6 dropped below pre-treatment production levels, Fig. 1. These results seem to show that fines migration continued. For example, within 30 days of treatment, solids production in Well 4 had increased rapidly with a corresponding production loss.

|

|

Fig. 1. Normalized production increase after zero, three and six months for the wells treated with HF (excluding Well 6).

|

|

HF conclusions. After these treatments, the overall conclusion was that HF systems remove formation damage and initially stimulate production, and that acetic preflush is beneficial in these treatments. However, rapidly declining production after treatment seems to indicate renewed fines migration.

For acid treatments to be economically viable, control of fines migration is vital to sustain production improvements over time. Also, the treatments had to be simplified. The number of fluid trains used had to be reduced to simplify logistics, lower costs and reduce the risk that all stages of treatment were not being uniformly injected into the heterogeneous formation. These conclusions led to the evaluation of organic clay acid treatments.

ORGANIC CLAY ACID TREATMENTS

Based on previous studies, an OCA treatment must have the fluids optimized for the specific mineralogy and treating temperature for the study reservoir, a process that requires determining appropriate initial concentration and ratio of hydrofluoric and boric acids, and concentration of the organic acid (the chelant), as described above. However, because only a few cores were available, the optimization process had to rely heavily on geochemical simulations. To calibrate the geochemical model, a number of treatments using different OCA formulations were pumped, and the pressure response during the treatment, geochemical analysis of the flowback and post-treatment production were used to calibrate the model and optimize the treatments.

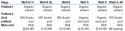

The first well, Well A, used the best acid formulation based on the service company engineering guidelines for the mineralogy; these guidelines included an acetic acid preflush followed by an OCA with virtually no free HF and a high concentration of organic acid. Table 3 shows the treatment design for each OCA-treated well. Well A was treated in two stages; each stage is listed separately.

| TABLE 3. OCA treatment design |

|

Straddle packers were used to isolate the upper and lower sands for each of the two stages on Well A. During first-stage pumping, when injecting the OCA, no decrease in the surface pressure was observed. This observation indicated that the fluoroboric acid had dissolved very little of the clay. So the second stage was pumped using an OCA fluid with a higher concentration of HF. This second-stage treatment did not result in a substantial pressure drop during the acid injection; however, the increase in post-treatment production (by a factor of 1.5) indicated that most of the damage had been removed.

In Well B, a geochemical simulator was used to determine an optimized OCA treatment, a treatment that effectively increased the HF concentration and made appropriate corresponding adjustments to organic acid concentration. (This decision for the optimized OCA treatment was based on experience in Well A and previous studies of OCA.) Acid volumes were increased from the 3-ft wellbore radial penetration of the previous treatment to 4-ft radial penetration, to ensure complete treatment of the critical formation matrix.

During treatment of Well B, at the end of the acid stage, the surface pressure dropped by more than 1,000 psi, which indicated the dissolution of clays and fines. The post-treatment production increase, by a factor of 2.4, was also evidence of effective stimulation, thereby confirming the validity of the previous laboratory study and the calibration of the geochemical model for this particular formation.

Good results on Well B led to the idea of using a similar acid system to stimulate wells thought not to be too severely damaged. So the treatment stages were adjusted to include a stage of organic mud acid before the OCA to treat selected intervals in the wellbore (sands), each of which was isolated with downhole packers and treated separately in turn. After treatment, Well C production reached levels not previously seen in this field, though treating pressure only decreased by about 200 psi during treatment. A similar treatment in Well D yielded similar results.

With knowledge gained through Well D and the optimized OCA system performing as expected, the evaluation focus moved to improving the economics of the treatments. A renewed effort began to correctly determine the damage mechanism in candidate wells to appropriately tailor the fluid selection and volumes, which included reducing both the volume and the number of stages. However, because fines migration was recognized as a fieldwide problem, the stages used for subsequent wells were similar to those used in Well E, only with different concentrations of free HF based on the specific suspected damage mechanism for each well.

RESULTS

Initial production immediately after the OCA treatments was similar to the results of the initial field trials. However, the sustained production improvements with the OCA system after three and six months were significantly different, on average two times higher than the results from wells in the initial trials, Fig. 2. This is very different from the trend when using HF-based fluids where, in most cases, after three months the production has fallen to below pre-treatment levels. (Results from Wells C, D and M, along with Well 6 from the HF stimulation trials, are shown separately in Fig. 3 because production rates in these wells were much higher than in the other wells.)

|

|

Fig. 2. Normalized production increase after zero, three and six months for the wells treated with the organic fluoroboric acid (excluding Wells C, D and M).

|

|

|

|

Fig. 3. Normalized production increase after zero, three and six months for the four high-volume wells.

|

|

The unexpected production decline in Well D is because of depletion and water breakthrough; the watercut increased from below 50% to above 80% in the six-month period following the treatment.

CONCLUSIONS

An OCA is a simple, versatile acid system that can be used as the main treating fluid in high-clay-content formations and low-temperature reservoirs. Unlike mud acid treatments, the OCA also provides effective fines and clay stabilization. In this study, both mud acid and OCA treatments delivered immediate post-treatment production improvements. However, only the fines migration control provided by the OCA sustained initial production improvements—for six months in this study—which helps to maximize the net present value of the treatment.

In many cases the OCA benefits from use of an acetic acid preflush. The increase in post-treatment productivity is equivalent to that generated by a half-strength mud acid, but without the characteristic rapid decline in production because of renewed fines migration.

The concentration of free HF in an OCA system must be optimized with respect to mineralogy and surface area of the clays in a specific reservoir. If the HF concentration is too low, migrating fines may cause plugging of pore throats and cause treatment to be aborted. Too high an HF concentration may result in precipitation and deconsolidation of clays in the matrix.

Good knowledge of the mineralogy and mineral species is vital to engineer viable solutions, to select the right fluids and, ultimately, to optimize matrix stimulation treatments in high-clay-content formations. Calibration of treatments for a given field, close monitoring of production from treated wells and a willingness to experiment on treatment design are also crucial for successful treatments.

ACKNOWLEDGMENTS

This article was prepared from SPE 126719 presented at the SPE International Symposium and Exhibition on Formation Damage Control held in Lafayette, Louisiana, Feb. 10–12, 2010.

|

THE AUTHORS

|

| |

Oscar Julian Jaramillo is a Stimulation Technical Engineer and Reservoir Technical Consultant for Petrobras Colombia, responsible for stimulation design and reservoir optimization. Mr. Jaramillo earned a BS degree in petroleum engineering from the University of America, Bogota.

|

| |

Ricardo Romero is the Well Intervention Manager for Petrobras Colombia and is responsible for the planning and development of completion, workover and stimulation of Petrobras´ fields in the country. Mr. Romero earned a BS degree in petroleum engineering from the University of America, Bogota.

|

| |

Art Milne is the Latin American Reservoir Stimulation Domain Manager for Schlumberger. He joined Dowell Schlumberger in 1979. His expertise covers stimulation and sand control. Mr. Milne earned a geology degree from the University of Edinburgh.

|

| |

Alexis Ortega is a Stimulation Technical Engineer for Schlumberger in Bogota, Colombia. He has more than 10 years of experience with Schlumberger. Mr. Ortega earned a BS degree in petroleum engineering from the University of America, Bogota.

|

| |

Manuel Lastre is a Fluid Technical Engineer for Schlumberger in Bogota, Colombia. He has more than five years of experience with Schlumberger in various technical roles. Mr. Lastre earned a BS degree in petroleum engineering from the National University of Colombia, Medellin.

|

|