GE Oil & Gas President and CEO Claudi Santiago’s vision is to raise the safety and reliability standards of oilfield equipment to those of the airline industry.

Pramod Kulkarni, Editor

|

|

|

Claudi Santiago is the President and CEO of GE Oil & Gas. Appointed to his current role in 1999, he has led the business through a period of significant growth. Mr. Santiago joined GE in 1980 as a project manager with GE Information Services. After moving to Paris to lead GE Information Services in Europe in 1997, Mr. Santiago joined the newly acquired Nuovo Pignone business to establish an aftermarket services unit. He holds a master’s degree in computer science from the Universidad Autonoma of Barcelona and has completed postgraduate studies at INSEAD in Fontainebleau, France, and Georgetown University in Washington, D.C.

|

|

General Electric (GE) is the company that Thomas Edison launched in 1878 with the invention of the electric light bulb. The circular GE logo is familiar on light bulbs as well as home appliances from toasters to refrigerators. The modern multinational enterprise that is GE is engaged in many consumer and industrial sectors, including aviation, nuclear, transportation and health care. The latest innovations even include a high-power white LED light that will permanently enshrine Edison’s incandescent light bulb as a museum piece.

Under CEO Jack Welch, GE became a darling of the blue chip investors as a dynamic growth engine. Now with Jeffrey Immelt at the helm, GE continues to reinvent itself as a corporate giant that can make a significant impact on a given industry through organic growth and strategic acquisitions. In the oil and gas sector, GE has a historical presence in upstream and downstream applications that require large-scale turbines and compressors. Over the last 15 years, GE has made a rapid ascent in the upstream services sector through the acquisition of stellar oilfield companies: Nuovo Pignone (1994), VetcoGray (2007) and Hydril (2008). In October 2010, GE acquired Dresser Inc. an industry pioneer with equipment offerings for oil and gas ranging from production and processing to power generation and fuel distribution. These acquisitions have helped GE extend its vertical reach in the gas compression and power generation arena, as well as establish a leading presence in the subsea production and controls sector. In 2009, the GE Oil & Gas business segment, which also offers wireline and drilling measurement solutions and pipeline inspection and integrity services, had revenues of $7.7 billion with a 12,000-strong employee base.

Delegates to SPE’s annual technology conference in September 2010 in Florence, Italy, were greeted at the airport with large welcoming billboards from GE Oil & Gas, which had moved its global headquarters there after the acquisition of Nuovo Pignone. President and CEO Claudi Santiago is based in Florence and took time out of his busy schedule for an exclusive interview with World Oil to share his vision for GE Oil & Gas and the upstream sector at large.

World Oil: GE is a recognized multi-national industrial company, but a relative newcomer to the upstream oil and gas industry, where the company has achieved a high profile through acquisitions and consolidated growth. Are you pleased with your current standing and what do you hope to accomplish in the near future?

Claudi Santiago: Over the last 10 years, we’ve made tremendous progress. Revenues have grown from $1.6 billion in 2000 to $7.7 billion in 2009. We have greatly diversified our technology and services offering, including in subsea through the acquisitions of VetcoGray and Hydril, while also rapidly expanding our global footprint. Our installed base is strong and our service capabilities continue to increase. To illustrate, aftermarket services have grown from 30% of revenues in 2000 to 42% of revenues in 2009; and from 2000 to 2009, aftermarket services orders grew nine times.

We have recently had wins in several projects—for example, in Qatar, on Gorgon, in China’s East to West Pipeline, and offshore Brazil and Angola, positioning us for strong and sustainable growth. But we’re never totally satisfied. Our aspiration is to be the technology leader through our passion for reliable innovation.

WO: Is GE Oil & Gas interested in acquisitions in the upstream exploration sector such as seismic?

Santiago: We’re mechanical engineers. I don’t expect us expanding much beyond our core competencies in rotating equipment, subsea, deepwater and other advanced technology.

WO: How have VetcoGray and Hydril assimilated into the GE enterprise and adapted to the corporate culture?

Santiago: Assimilation is never easy, and changing cultures is complex. But these companies are happy to be a part of GE, with opportunities for major technology investments and access to research and development resources from other GE business segments, such as aviation, nuclear and transportation. What is more, under GE’s ownership, these businesses are thriving and delivering for an expanding customer base.

WO: How has the Deepwater Horizon incident and the Gulf of Mexico oil spill affected your business and your strategic thinking?

Santiago: The Deepwater Horizon accident was devastating. Our thoughts are with families that lost their loved ones, and we’re saddened by the environmental impact. Clearly, the accident will result in more regulation and require more attention to safety, remote sensing and diagnostics. All of these requirements point us in the direction of the aviation industry that has such standards already in place.

In fact, embedding an aviation mindset has been a key dynamic within our business for a number of years. In engineering, we have focused on driving through a five-step approach of reliable innovation that eliminates risk for our customers and delivers benefits in terms of safety, reliability and performance. In summary, our approach is to deliver reliable technology through close collaboration and partnership, application of deep domain expertise, including know-how from other GE businesses such as GE Aviation and Healthcare, and testing products to destruction so that we understand the limits and mitigate risks for customers.

Learning from the aviation industry is also reflected in our application of remote monitoring and diagnostics across our equipment portfolio so that we can monitor in real time the performance of our installed base. We also borrow more directly from aviation by exploiting GE Aviation technology, for example, power crystal technology to increase power and improve efficiency, and we have a big R&D focus on power density for high-pressure ratio compression. In our supply chain, we rigorously enforce a “prevention and stop” safety and compliance culture that has its roots in aviation’s highly regulated safety culture, and we also rotate many of our senior engineers through GE Aviation, so that both businesses learn from one another.

Prior to the Macondo well blowout, we’ve been working to improve well safety. GE can bring technology and reliable practices from the aviation industry into oil and gas. GE has created good businesses in regulated industries—aviation, healthcare and nuclear. We have a lot to offer to the oil and gas industry in terms of how to innovate and create growth while meeting regulatory requirements.

WO: US Energy Secretary Stephen Chu confirmed your thinking when he recently said that engineers aiming to boost the safety of offshore drilling should draw inspiration from the airline industry. What are some GE Oil & Gas technology developments that will foster growth for the company in such a regulated environment?

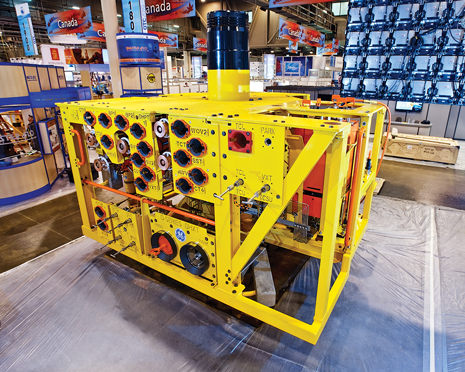

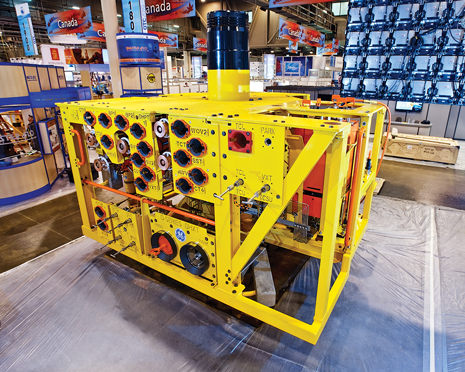

Santiago: GE plans to spend close to $1 billion over the next three to four years in technology spending. We have several new product developments and R&D efforts in progress to improve the power density of our turbines and compressors to make them more compact and more efficient as well as more environmentally friendly. Examples include the LM6000 compressor package designed specifically for the oil and gas industry and the DHXT Series deepwater horizontal tree and integral control system, Fig. 1.

|

|

|

Fig. 1. The DHXT Series deepwater horizontal tree and integral control system is designed to operate in water depths up to 10,000 ft and at pressures up to 15,000 psi. The streamlined design reduces standard industry horizontal tree footprint by 12% and weight by 10%.

|

|

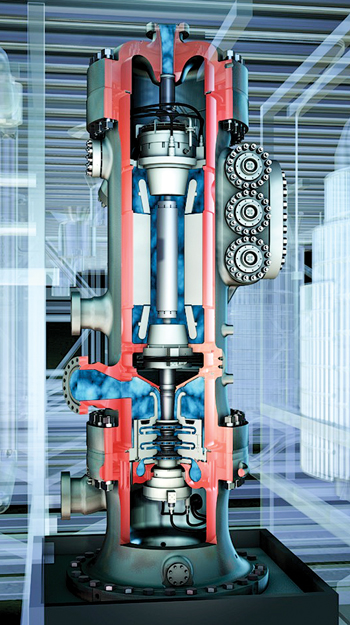

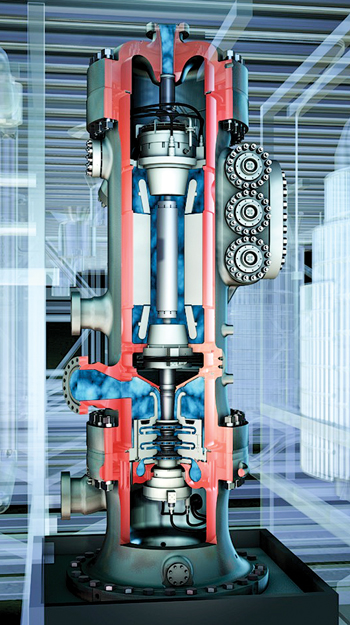

Our new subsea control systems are smarter and are capable of handling more data. The innovative Blue-C subsea compressor is a world-first and has robust design, including a single-sealed housing to withstand extreme pressures and temperatures, Fig. 2. The first unit is being tested at 1,900-m water depth for Statoil, and three additional units are on order.

|

|

|

Fig. 2. Co-developed with Aker Solutions, Blue-C is the first subsea compressor for unattended operation

at over 1,000 m below sea level.

|

|

To improve reliability, we’ve built the world’s longest compressor test station in the oil and gas industry in Massa, Italy, Fig. 3. Here, we’re able to test LNG units at full load and under expected local conditions in terms of compression requirements and gas composition. As such, we can test real limits and ensure peak performance before the equipment is installed in the field.

|

|

|

Fig. 3. GE Oil & Gas has invested over $9 million in the world’s longest test bed for thermodynamic and mechanical running tests on large centrifugal compressors for LNG and ethylene applications.

|

|

WO: What is your view of the future for fossil fuels and renewable energy?

Santiago: We feel natural gas is a fuel of the future and will be capable of providing for our energy needs for the next 100 years. In the gas sector, GE Oil & Gas is engaged in major LNG projects in Qatar and Australia. We also feel that shale is a potential game changer. The initial technology innovations have taken place in the US, and now there are clear opportunities in international arenas.

We’re also interested in how the energy sector will evolve in the future. Diversity is key to supply and to security. We’ll need fossil fuels—both oil and gas—and coal is also important. In the carbon sequestration arena, we’re installing a CO2 pump in the Tupi Field for Petrobras. We believe in renewable energy as being a part of the solution. I’m an optimist who believes in the future of an integrated and diversified energy industry.

|