PROJECT MANAGEMENT

Project risk: A key consideration for upstream project management

A scenario-based approach to identifying, assessing and mitigating risks in a project’s early stages is a tried and tested method for achieving successful outcomes.

David Wood, David Wood & Associates, Lincoln, UK; Greg Lamberson, International Construction Consulting, LLC, USA; and Saeid Mokhatab, Contributing Editor, LNG, World Oil

Project management must involve detailed evaluation, assessment and mitigation of a wide range of risks in order to make the right decisions at the appropriate times. By managing risk, a company can greatly reduce project costs, improve the project schedule and ultimately increase stakeholder returns without stumbling over unexpected events. A definitive process is required in order to systematically and appropriately identify, assess, control and reduce risk (and/or exploit uncertainty and opportunity in some cases) during all phases of a project.

There are three main areas of project risk:

- Pre-FEED or conceptual risks

- Technical (engineering and design) risks

- Execution (construction, installation, start-up and commissioning, operations) risks.

If project risks, particularly project execution risks, are not managed through comprehensive assessment and measured responses, the consequences frequently come back to haunt all of the project stakeholders, and can lead to human and financial catastrophes. An example of such is the Petrobras P-36 platform installed at Roncador field offshore Brazil. The platform overturned and sank in March 2001 after three explosions killed 11 workers, Fig. 1.

|

Fig. 1. The Petrobras P-36 platform installed at Roncador field offshore Brazil overturned and sank in March 2001.

|

|

In this article, we identify risks by major project phase and describe a system that identifies and communicates these risks to management before the start of each major project phase.

DEVELOPING A RISK MANAGEMENT PLAN

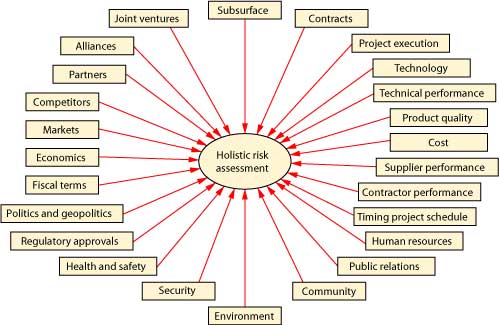

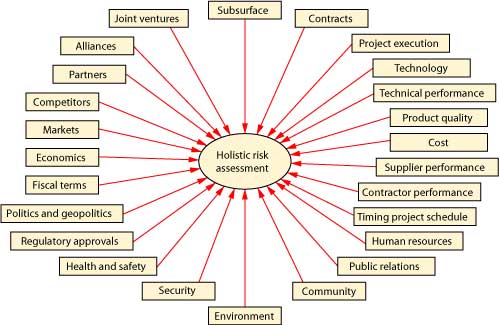

An integrated Risk Management Plan (RMP) should address all project risks and their potential effects on a project’s technical performance, cost, schedule, execution, safety, security, health, community and environment, Fig. 2. Risk should be addressed holistically; to the extent that it is possible to predict impacts, this assessment should include all stakeholders, involved parties, all phases and all types of project exposure and uncertainty. The RMP should allow the company to address all actions necessary for fulfilling contractual obligations, and to continuously incorporate the results of all assessments and mitigation/exploitation strategies concerned with uncertainties as they become better defined.

|

Fig. 2. Spectrum of risks and uncertainties affecting oil and gas assets and projects.

|

|

Specific equipment operational risks, such as control valve functionality, construction yard locations or installation sequencing, should be captured by hazards-and-opportunities (Hazop) analyses incorporating detailed risk assessments at the equipment and control level. Such detail should be specified in the project’s RMP, which will ultimately be passed on to plant operators once the facility is operational. However, in addition to the technical risks covered by the Hazop, it is prudent for a project RMP to define a specific Project Execution Plan (PEP), which includes the techniques, processes, plans and procedures to be used or developed for risk assessment and management during the delivery of a construction project. The PEP should be project specific. A project-wide RMP should define the specific assessments to be conducted, the timing of the assessments, and the roles and responsibilities of those involved. Risk management, while required for all projects, is scalable, and each RMP and its component PEP should define the level of detail and analysis that is prudent in the project context.

An Initial Risk Management Plan (IRMP) should be developed for assessments to be conducted before detailed design. An IRMP will usually be conducted during a project’s conceptual, feasibility or pre-FEED analysis. The RMP should be updated before the start of detailed design and revisited before the start of construction/installation. A key part of an RMP is that it evolves as a project unfolds, incorporating follow-up and close-out of all risks and opportunities contained in the assessments of specific uncertainty events.

All companies, whether small or large, E&P companies, engineering firms or EPC contractors, should have a comprehensive and systematic approach to managing project risks. The E&P company, as the project client and/or sponsor, should have its own system, as well as detailed coordination procedures that outline the goals and expectations of the contractors’ RMPs. These coordination procedures should be clearly communicated to the contractor during the tendering phase. The engineering firm or EPC contractor should also have a comprehensive risk management program in place that meets the client’s requirements and that can be integrated with the client’s RMP.

PRE-FEED RISKS

During the pre-FEED or conceptual phase, an approach should be developed as part of the IRMP to identify a comprehensive list of project issues, possible events and their likely impacts. The analysis should be systematic, focusing on all aspects of the project, depending on the project complexity. The scope can be broad and include field development (drilling and initial operations), logistics requirements, geographical locations, technical issues and/or other aspects.

The IRMP should address the resolution of key issues and offer guidance on the appropriate levels of senior management involvement. It should also address and document transparently how issues are classified and assimilated. All significant issues (those with a substantial negative or positive impact) need to be brought to the attention of senior management.

Scenario-based risk assessment. A scenario-based assessment can be aided by a probability-vs.-consequence matrix. Such matrices can take any of several formats varying from purely qualitative to quantitative, with different numbers of individual cells. Figure 3 shows a 5 x 4 matrix (i.e., five levels of event likelihood and four levels of impact consequences should an event occur). Each cell in the matrix represents a coded outcome with groups of outcomes color coded, usually using variations of a traffic-light approach (red for unacceptably high-risk events requiring mitigation actions and green for acceptably low-risk events requiring little or no control actions). Table 1 shows definitions of likelihood and consequence levels for this sample matrix. Definitions, including quantitative magnitudes, of the impacts are project specific, and it is important that they be defined, understood and agreed upon by all involved in project risk assessment.

|

Fig. 3. A sample likelihood-vs.-impact risk matrix.

|

|

| TABLE 1. Definitions of impact consequences and likelihoods for sample 4 x 5 risk matrix |

|

|

Scenario-based assessments using a risk-matrix approach are recommended in order to properly address, rank and present assessment results for all project phases. They can often be complemented by the use of “bowtie” and/or “butterfly” diagrams that identify the links among events, their causes and potential consequences/outcomes, Fig. 4. Such approaches help develop recognition that events can have multiple outcomes and multiple causes. They also focus mitigation strategies on the ultimate causes rather than just the events or their potential outcomes.

|

Fig. 4. Bowtie and butterfly diagrams are useful for identifying multiple outcomes and multiple causes of events and to focus mitigation strategies on the ultimate causes of identified risks.

|

|

Scenario-based assessments involve the gathering of experienced project personnel in specific disciplines (i.e., construction, procurement, operations, engineering, regulations, safety, environment, logistics, schedule and control, public relations, legal, etc.) in a workshop environment or as an expert panel. Such a formal gathering uses the experience of individual staff members and the interactions of a multi-disciplined group to brainstorm potential problems.

Once established, the expert group may develop and evaluate potential mitigation strategies. These strategies should be quantified with regard to costs and then re-risked to determine if the cost of the mitigation, and secondary consequences it may initiate, justify the value of the result (e.g., if the mitigation moves the risk/probability from the “red” area toward the “green” area of an associated risk matrix). The mitigation strategies should then be discussed and agreed upon where possible. When mitigations cannot be agreed upon, a resolution process (contained in the IRMP and not necessarily democratic) should be adopted to establish a recommended way forward. The risk mitigation measures and action plans should be put in place after approval by the appropriate level of management, with clear definition of the individuals accountable for their implementation. It is crucial that these mitigation measures and action plans be tracked to project completion; ideally, they should be documented in a risk register.

Risk assessments during the pre-FEED or conceptual phase should be performed as set out in the IRMP. As the project moves forward, new issues will be identified and analyzed in the same manner. However, the earlier in a project that risk mitigation decisions are made, the more significant their impact is likely to be in controlling ultimate project costs, Fig. 5. Late-stage decisions focused on risk reduction during detailed design commonly result in cost and time escalations. A comprehensive Conceptual Risk Assessment (CRA) should therefore be initiated before a FEED study and long before detailed design.

|

Fig. 5. Cost and schedule-control benefits of early (planning phase) risk assessment and risk mitigation decision making.

|

|

Depending on complexity, most energy facilities projects benefit from a preliminary Hazop review. This should be conducted using the design detail available in the draft Basis Of Design (BOD), including layouts, preliminary Planned, Numbered and Initialled Drawings (PNIDs), equipment data sheets, flow diagrams and information on likely hazardous materials, as well as the draft project design specifications. The purpose is to identify potential design hazards that need to be addressed in the detailed design phase.

Departures from required asset performances and reliability should be considered during the CRA. All areas of project risk should be assessed. The CRA is based on preliminary drafts of the key early project documents, including the Initial Project Execution Plan (IPEP).

This early-stage risk analysis enables the project team to move up the learning curve and reduce the likelihood and potential impacts of identified risk events, Fig. 6. In some cases, this analysis should allow personnel to eliminate the causes of potential events.

|

Fig. 6. Early-stage risk assessment aids learning and enables decisions to be made under conditions of less uncertainty.

|

|

TECHNICAL (ENGINEERING AND DESIGN) RISKS

As a project moves into the definition phase, the scenario-based approach can be further developed into an Engineering and Design Risk Assessment (EDRA), which should be conducted before initiating the detailed design work. Depending on the size and complexity of the project, the EDRA scope can be very broad and may cover a broad range of project aspects including regulatory approvals and third-party interfaces, contracting strategies, community impacts and relationships, system abandonment at end of the assets operational life, and construction. These are in addition to specific design aspects such as number of trains, operability and sparing philosophy. The EDRA may, but does not generally, address specific project details such as control valves or detailed procedures. These are normally covered during Hazops and are subject to specific risk assessments clearly identified in the RMP.

The PEP, Work Breakdown Structure (WBS), BOD and operating philosophy are typical project documents that are reviewed and used as the basis of the EDRA.

Design-phase Hazops. Hazard-opportunity analyses are a key ingredient of sound project risk management. These analyses are normally conducted after the design is frozen and/or before key deliverables such as PFDs and PNIDs are issued for construction. All plot plans, layouts, data sheets and vendor information must be available for review at the start of the Hazop. The purpose of a detailed design-phase Hazop is to address all potential process and operational hazards before finalizing procurement and moving into the construction/installation phase. Hazops are also conducted to stress test a facility, in order to verify that it performs to its specified design under a range of possible operating conditions.

A successful Hazop depends to a large extent on a well-documented, structured process in which the complete design is systematically analyzed for deviations from design and operational intent by a team of experienced technical, construction and operations personnel. The presence and involvement of those who will be responsible for operating a facility after commissioning is highly recommended in order to capture all of the anticipated operational issues (normal, cold and hot startups; normal or emergency shutdowns; normal, temporary and emergency operations; etc.) and focus them on responding to potential teething problems.

The results of the Hazop will include a comprehensive list of issues along with recommendations covering-in addition to engineering and operations-safety, health, community and environmental issues.

Responsibility for follow-up/close-out of Hazop items (coordination of the “list” as well as of each individual item) is documented, understood and followed up on by project management to ensure issues are resolved satisfactorily and closed out in a timely fashion. The Hazop coordinator/team leader should agree with actions to ensure that the recommendations have been addressed.

After completion of the Hazop, it is a prudent policy to mandate that no changes be made in engineering, design, construction or operation that materially affect the results of the Hazop without a thorough re-analysis. This should be rigorously covered under the project Management Of Change (MOC) plan, including appropriate approvals for initiation, evaluation and acceptance of changes.

All issues and action items stemming from the detailed design-phase Hazop must be ultimately resolved, and all affected project deliverables should be upgraded before the completion of detailed design. For a pre-commissioning Hazop, all issues and action items stemming from the Hazop must be resolved and all impacted deliverables upgraded before the facility is signed off for operations.

EXECUTION RISKS

The construction risk assessment is conducted before construction commences. Its scope can be very broad, covering all aspects of the construction phase. These include government/regulatory approvals and interfaces, contractor/subcontractor performance, component integration, weather window implications, interfaces and issues associated with the final construction plan. The construction risk assessment does not usually address very specific project details such as individual yard safety programs, welder qualification or detailed contractor procedures. These detailed issues are covered by specific risk assessments as identified in the RMP.

Detailed design documents and drawings, construction contracts, supplier quotations, cost estimates, long-lead item schedules and contractor plans are examples of input documents to be used when conducting the construction risk assessment. The purpose of the assessment is to identify project-level issues, hazards and plans to mitigate the risks and/or eliminate the causes of events that could have material impacts. The CRA also often develops into a valuable communication tool, in conjunction with its input to the risk register, for identifying and documenting project risks to management before starting project construction.

While we have here focused on only a small subset of project execution risks, in practice we recognize that execution risks cannot be considered in isolation from the full spectrum of asset risk and uncertainty.

Additional pre-commissioning risk assessments. Other areas of the project subject to specific risk assessments will be defined in the PEP and RMP. These areas may include, but are not limited to: special design details; contracting strategies; fabrication and loadout activities; heavy lifts; installation activities; early construction work; hookup and commissioning activities; and pre-commissioning Hazop.

CONCLUSIONS

All projects suffer exposure to vulnerabilities and uncertainties. These are often encompassed by a project’s or company’s definition of “risk.” Properly managing this risk requires a structured, systematic and holistic approach involving open communication, transparency, accountability from experienced personnel and flexibility to adjust responses to risks and opportunities as they become identified and more clearly understood.

One of the keys to success is the early identification, assessment, evaluation and resolution of risk in all phases and at all levels of an energy project. The scenario-based approach is a solid, tried and tested method for successful project execution. In all phases of a project, regardless of the source or which party has liability, there must be an effort to work together to manage the risk and share information related to it.

|

THE AUTHORS

|

|

Dr. David Wood is the principal consultant of David Wood & Associates, UK, specializing in the integration of technical, economic, risk and strategic information to aid portfolio evaluation and management. He has more than 25 years of oil and gas experience spanning technical and commercial operations, contract evaluation and senior corporate management. Industry experience includes Phillips Petroleum, Amoco and Canadian independents. From 1993 to 1998 he was UK managing director for Lundin and then for Morrison Petroleum. He is based in Lincoln, UK, but operates worldwide. He can be contacted at woodda@compuserve.com.

|

|

|

Greg Lamberson is the principal consultant of International Construction Consulting, LLC, USA, with over 25 years’ experience in business, project, engineering and construction management for upstream and midstream oil and gas. He is accomplished at working within integrated environments with multidisciplinary and multicultural staffs to ISO, US and various foreign standards, procedures and specifications in a variety of geopolitical climates.

|

|

|

Saeid Mokhatab is currently consulting for multinational oil and gas companies and research organizations in the upstream and downstream energy sectors on a domestic and international basis. His areas of expertise include technical and commercial areas learned while working in senior technical and managerial positions at several international oil and gas EPCM projects, partnerships and joint ventures as a solution integrator and key source of expertise.

|

|

| |

|