Drilling Report

US mid-continent operator tests deep Oklahoma potential

Customized tools make HPHT completion possible.

Kenny Bennett and Jerry Heimer, Smith Services, Darren Seagrest, GHK

During the 1960’s, US land operator GHK began pioneering efforts to explore the deepest areas of the Anadarko Basin. By the late 1970s, the company had extensive experience in deep drilling and had accumulated over 400,000 net lease acres. In 1981, GHK entered into a joint venture with Mobil to drill a series of ultra-deep exploration wells. One of those wells was the Robinson 1-1 well.

The expansive Hunton natural gas field was thought to be split into two distinct producing zones at 23,000 ft and around 29,000 ft. In 1981, drilling began on the Robinson 1-1 well near southwest Elk City, Beckham, OK. By late 1982, the well reached 29,241-ft TD in the Devonian Hunton formation. It was then cased to 28,581-ft MD.

When gas economics turned negative in 1983, the deep Hunton well was plugged and abandoned, to wait for higher gas prices that would make re-entry cost effective. Prior to drilling this well, the formation had never been drilled to the deeper 29,000-ft zone.

REOPENING THE TREND

|

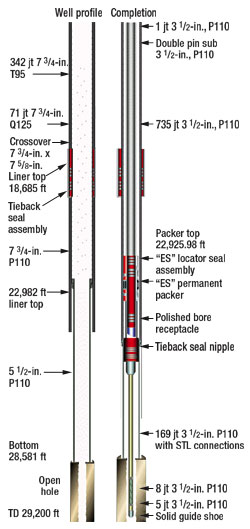

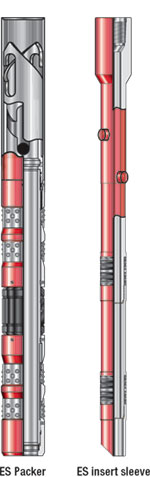

Fig. 1. Not much was known about the well’s condition after more than 20 years (right), so a tieback string was set prior to running the completion string (left).

|

|

Twenty-three years later in 2005, Robert A. Hefner III, GHK’s owner and founder, felt that the time was right to re-evaluate the play, so the company began a new exploration program. GHK’s landmen acquired 100% mineral rights to the land around the Robinson 1-1 well, preparing for a deep test in the Hunton.

Later in 2005, a snubbing rig was put into place, in case significant bottom hole pressure had developed. This rig would drill through the plug and re-enter the well. With the well opened and a drilling rig in position, GHK called on Jerry Heimer, Smith Services’ district manager in Piedmont, OK, to evaluate the project and determine a course of action to install a completion string and stimulate the well.

"GHK approached us with their goals for this well, and we spent a good three months planning the completion project before we ever went into the field," Heimer continued. "We looked at every angle to determine all of the variables beforehand. Aspects of the project that usually will make or break a job, like liner weight and pipe metallurgy, all take on critical importance when operating at these pressures and depths. We had a window for success."

Although GHK had complete well records, not much was known about the well’s condition. "Low natural gas prices in 1983 led to the well being drilled, but never tested," Heimer said. "We went in on faith, counting on 20-plus years old data to formulate a completion plan."

The plugging data was very sketchy at the time the operations began on the well. Drilling consultant Gary Hollis’ had originally drilled the well. His knowledge of the earlier plugging work was a critical component of the operational success of the project, especially as the workover went deeper in the well.

The workover went smoothly. There was some trapped pressure, but it was handled with typical circulation methods. The plug was drilled without incident and the well was re-entered to the original TD. Then, the snubbing unit was rigged down.

No additional footage was drilled and no casing surveys were run. Amazingly, after all those years, the open hole was just as it was left.

FRACING THE WELL

|

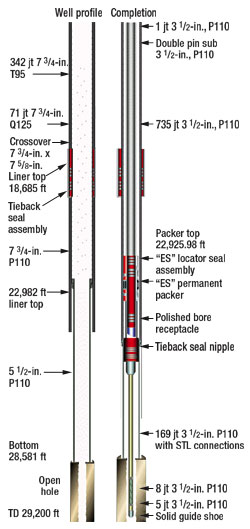

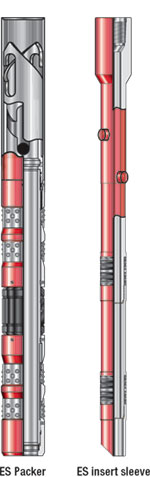

Fig. 2. The Extreme Service packer (left) and insert sleeve (right) were fitted with 13Cr components for reliability during acid-fracing.

|

|

Research between GHK and Halliburton led to the decision to acid frac the well. Casing quality became an issue early on in the project. The combination of the age of the tubulars and the unknown conditions they would be exposed to during production made the casing unsuitable for supporting a long, heavy completion string that would be exposed to significant pressures.

"Operating at these depths was truly ‘wildcat’ territory, and so neither Smith Services nor GHK could be sure how the downhole environment might change once a stimulation operation was performed at 29,165-plus feet," said Heimer.

The decision was made to set a tieback string prior to running the completion string. The 7-3/4-in., 46.10-lb string was tied back to surface at a depth of 18,685 ft MD. The complete 7-3/4-in. string weighed more than 750,000 lb.

"GHK pulled out all the stops to make sure this completion run was a success, and the tieback string is a good example of this," Heimer said. "That string took a long time to run and set due to its weight. Once it was installed though, the quality through-bore these sleeves provided made tripping the rest of the completion system a much easier task. The string also eased concerns about casing performance during production."

In order to achieve the completion objective set, a customized suite of tools was tailored to the hostile environment. Downhole temperatures were expected to reach 400°F at 12,000 psi, with pressures rising to more than 18,000 psi during the planned acid fracturing operation to follow.

Heimer worked closely with Mike Roberts, Smith Services’ senior engineering manager in Houston, to put together a combination of HPHT packer and setting system that would meet the project’s requirements. The Extreme Service (ES) Packer was selected because of its combination of aggressive slip design (four sets of slips) and PEEK nitrile elements for HPHT performance. The packer was fitted with specially-fabricated 13Cr components to ensure reliability during acid-fracing.

Developing a setting tool for the ES packer required reinforcing components to endure the 50-plus hour trip to depth. A hydraulic setting tool was modified for this project, incorporating an upgrade to 235,000 lb shear from 50,000 lb, PEEK o-rings for high pressures and temperatures and a mechanical release system to separate it from the liner top packer.

"The setting tool was one of the most important components, because of the length and weight of the tail pipe, and the long distance we had to trip it," Heimer said. "If the packer had set prematurely, we would have had problems. There was always the outside chance that the packer could set prematurely and the 65,000 lb tail pipe could separate, causing it to hit the liner top below. With as much as 20,000 ft of freefall, that tail pipe could have caused an incredible amount of damage."

A 40-ft Polished Bore Receptacle (PBR) with a redesigned tieback stem was fitted below the packer to help support the weight of the completion string. Upgraded seals, rated to 450°F and 15,000 psi, were included on the 43-ft long seal assembly to ensure performance.

The rig crew tripped the ES packer with PBR, tieback stem, setting tool and 6,200-ft tail pipe to depth and set them without incident. The completion string was comprised of 3-1/2-in., 12.95-in. P-110 grade tubulars, with TSHD connections, and required 52 hr to reach the 29,165 ft MD target depth.

Once the completion string was set, an acid frac was performed on the formation. The frac was pumped down a 3-1/2-in. tubing string at a maximum 15 bpm and 18,513 psi. The job was a series of high temperature gelled fluid and Hot Rock Acid stages. Pressures of more than 18,500 psi were measured at surface during the operation as downhole temperatures reached about 400°F, while holding 4,000 psi on the annulus.

After stimulation, the well produced unsatisfactory levels of natural gas, carbon dioxide (80%) and water. The project was once again abandoned.

FUTURE

Has GHK given up? Certainly not. There are very few penetrations testing deep, high pressure horizons compared to shallower reservoirs. Therefore, future activity will be in newly drilled opportunities.

The deep, high pressure, high temperature horizons are America’s largest remaining source of undeveloped natural gas. GHK will continue exploring for and producing deep, high pressure onshore natural gas, targeting one of US’ most prolific natural gas regions: The Mid-Continent.

"While the end result for this well was certainly not what we hoped for, we made some significant achievements," Hefner commented. "By drilling and completing a well of this depth, temperature, and pressure, we once again extended the technology necessary for drilling the deep onshore regions of the world. We raised the bar for what are traditionally considered high-pressure, high-temperature environments, and expanded the possibilities for reaching challenging formations in the future."

|

THE AUTHORS

|

|

Kenny Bennett has 26 years of oil experience in sales, marketing and management. He worked for Cudd Pressure Control for 15 years and has been with Smith Services Completions Group for the past four years as senior technical sales representative. Bennett works in the Oklahoma City and Piedmont, Oklahoma offices.

|

|

|

Jerry Heimer has 37 years of operations experience in the oil and gas industry with Baker Oil Tools, Precision Oil Tools and Milcor Oil Tools. Heimer joined Smith Services Completion Systems in 1998 as district manager.

|

|

|