Intelligent Well Completions

JIP seeks to identify value of intelligent well systems

Funded by industry sponsors, a university-led project is developing methods for recognizing, quantifying and increasing the added value of intelligent well systems technology.

Dr. David Davies, Institute of Petroleum Engineering, Heriot Watt University, Edinburgh, Scotland

The upstream oil and gas industry is being called upon to increase hydrocarbon supply, while, at the same time, raising the level of ultimate recovery. In addition to increasing activity levels, there is a continuing drive to reduce costs while efficiently using scarce (manpower and capital) resources.

Many, separate technical initiatives have taken place over the last few years that have supplied the separate parts of the jigsaw that is being assembled to meet the above objective. A new generation of measurements, technologies, processes and workflows is being developed to provide the necessary hardware, communication and software tools to provide information and analysis for timely, informed, decision-making.

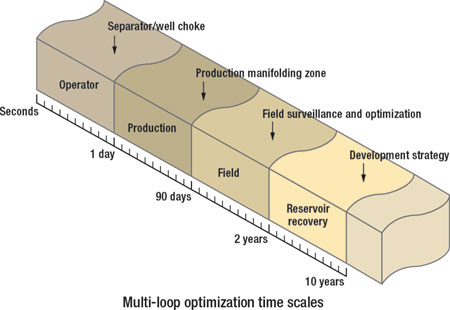

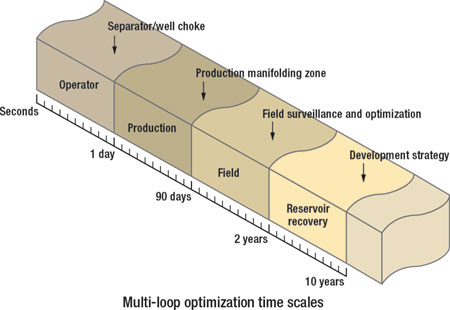

The immediacy of such decision-making has been captured in widespread use of the terms “real-time”, “(just) in-time”, “relevant-time,” etc. These all hint that decisions are made at a series of times that are appropriate to the particular process cycle being considered, Fig. 1.

|

Fig. 1. The multiple optimization loops and their time scales.

|

|

Intelligent Completions is one of these technologies. Increasingly, it is used widely in many field developments, due to its ability to rapidly identify events and to reconfigure the production network – at a completion zone or well or production network/ facility level – as appropriate. Implementation is driven by its perceived ability to improve field and well economics. One example is by generating cost-effective increases in ultimate field recovery (reserves) with improved, overall well performance (increased flowrates, plus reduced unwanted fluids) through timely, high-performance reservoir/ well monitoring and optimization.

Some years ago, a project was started at Heriot Watt University, Edinburgh, UK, under the author’s direction, to develop tools required to recognize, quantify and increase the “added value of intelligent well systems technology” (IWsT). This initial work, originally part of a European Union-funded project, has now developed into a Joint Industry Project (JIP) supported by a number of sponsors. The original project scope has been extended to include the majority of the application (i.e. non-hardware) aspects of the production and reservoir management areas. These are areas frequently associated with the initiatives being implemented by many, large oil companies under the banner of “intelligent-field,” “i-field,” “e-field,” “digital oil field,” etc.

THE MANUAL

The Manual is the project’s main reporting vehicle. It summarizes the progress and project achievements presented to the Steering Committee meetings. It covers the following subjects:

- A brief description of IWsT hardware – what IWsT is and how it works, Interval Control Valve (ICV) selection and operation criteria, sensors, etc.

- A checklist or “showcase” of the opportunities in a variety of field situations to create value with IWsT

- Screening techniques, parameters and processes to aid decisions on whether to install IWsT and, more specifically, what type of IWsT equipment for particular cases of different reservoir and/or well situations

- Techniques for evaluating the incremental revenue and cost – the value creation from IWsT implementation. It can be carried out using various financial techniques of differing levels of complexity

- Reservoir/ well simulation is used to compare the base case (conventional well) production forecast with one employing IWsT

- Identifying generic reservoirs where IWsT is the preferred technology. The interaction of an intelligent completion and the geological model is evaluated here. Generic, geological models have been constructed and systematically used to study the impact of geological heterogeneities on the recovery

- Sponsor real field case studies of potential value creation by IWsT. These are used to explore techniques available to maximize production and take advantage of the flexibility offered by IWsT and ICVs

- Role of IT systems for efficient handling and management of downhole information. Thought has to be given as to how the large volumes of high-frequency data that will be generated by the monitoring system will be managed (data monitoring, data storage, validation, archiving, data analysis and subsequent transmission to Engineering staff). Changes in workflow, job description and organization are required, if the full value contained in the data is to be derived.

The project has focused on developing tools required to recognize, quantify and increase the added value of IWsT. Many factors are considered when deciding whether to install IWsT. These include the choice of the number and type of flow control and flow monitoring equipment to be installed in a particular case. They must meet the criteria of being both “cost-effective” and “fit-for-purpose.” Some of these are described in greater detail in the following passage.

LOOKING FOR ADDED VALUE

The first stage was to develop an “Evaluation Roadmap,” showing the important parameters that need to be considered during the process. This was supplemented by a screening list (the showcases) that will help an engineer screen his well/ field portfolio to identify whether a similar field or well has already benefited from field-proven application of this technology. The basics of IWsT modeling and its optimization has been developed and used in a series of real-field case histories, where the added value from IWsT application has been studied and quantified.

The screening process recognizes, evaluates and prioritizes candidate wells or fields for completion using IWsT. The screening process is based on a series of steps as illustrated in the Road Map, Fig. 2.

|

Fig. 2. The Screening Process Roadmap.

|

|

The first of these steps, asks, “Why is IWsT being considered?” This relates to defining and assessing the technical and economic objectives of IWsT. The objective may be to decrease intervention costs and delay water/ gas production. It may be to increase drainage efficiency (reserves/ well ratio). Or, the objective may be to improve oil recovery/ waterflood performance and/or manage geological risk, etc.

A particular IWsT installation may often have multiple, possibly contradictory, objectives. These objectives may have different requirements for the performance of the installed hardware. Checklists to aid this process have been developed.

The second of these steps is to analyze and survey existing field information. This includes looking at the geology, geophysics, well logs, historical production, etc., to understand how many objectives can be met in terms of technical feasibility and acceptable risk. Consideration will be given to several questions. For instance, “Can the optimum, long horizontal section be drilled without difficulty?” “Can the optimum borehole diameter needed for installation of ICVs be provided?” “How is the increased risk of more complicated completions to be balanced against the potential for enhanced value?” Finally, “What is the reliability of the ICV and/or the control/ measurement system and the impact of their failure?”

An economic and reliability evaluation package, which addresses all these issues, has been developed.

A third step is to identify and evaluate well design criteria and resulting alternative strategies. These include determining the well, field production and/or injection requirements. The degree of control must also be ascertained (Open/ shut or fully variable ICV, or an ICV with a limited number of pre-set valve opening settings). Engineers must also determine any artificial lift requirements and prescribe what types of sensors are required to provide the basic data for well/ field diagnostic functions.

Sensor capabilities have been evaluated and a check list to aid the sensor selection process has been developed. A spreadsheet has been devised for quantifying the value of the numbers and type of ICVs and sensors to be employed.

The fourth and final step is to evaluate the identified design options. For example, is the reservoir suited to IWsT? A checklist of the detailed parameters, which should be considered for decision-making with respect to a range of reservoir types, has been developed. The performance of IWsT in a range of reservoir types, using statistical geological parameters, has been evaluated. Alternatively, the preferred option of a long-term prediction of well and reservoir performance from a history-matched simulation, can be made.

Another design option is to predict the well/ field performance. A long-term prediction of reservoir performance from a history-matched simulation is the preferred option.

The next part of the equation is to estimate the costs. Costs for drilling, completion, production, intervention, etc., need to be calculated and compared with the equivalent costs for the conventional well design case. Reductions in costs for pipelines, surface facilities, numbers of wells, well interventions, platforms, etc., due to intelligent completion installation, must also be included, as these are all significant value contributors.

The risk related to each phase of the project must then be analyzed. Realistic figures for reliability are required, to ensure that proper life-cycle cost figures are generated in the estimation tool provided.

The above factors are then all combined in a model of the economic performance of the well/ field. The appropriate risked, economic indices, e.g. Net Present Value, Real Options, etc., should be used. Various fields have been studied to evaluate the value creation potential through application of IWsT.

SHOWCASE OF WHERE VALUE HAS BEEN FOUND

Early experience with searching for IWsT added value indicated several things. First, a small fraction of the company asset portfolio delivered 80% of the value generation potential. Second, 50% of the IWsT value was in Ultimate Recovery Increase, but 80% of such wells were justified to management on Production Acceleration. This latter is easier to quantify and presents immediate, short-term benefit in increased production, speeding management approval.

Furthermore, many important aspects are identified that were difficult to quantify, e.g., reduced uncertainty for reservoir management decisions, selective zone stimulation and scale management and safety (less intervention and transport to the well site, reduced water and gas emissions, etc.). Early data gathering, combined with an ability to adjust well pattern (but it is necessary to take action), reduces downside risk during field development.

Also, the Operational Value of downhole data is significant. For example, this can bring new/ existing wells up to full production rate more rapidly than when using surface data alone. This can, at least partly, justify the cost of the IWsT installation, based on the more rapid well clean-up, the consequent saving in rig time and the reduced risk of damage to the well from produced sand.

Similarly, the unnoticed arrival of a gas cone could cause a well to be shut-in for days. Downhole temperature measurements, combined with a suitable model, would have identified the early stages of coning/ cusping, avoiding the loss of up to a week’s production.

The range of potential, economically justifiable opportunities has widened greatly in the last few years. This is based on a general acceptance of the robustness of the IWsT technology and the availability of lower cost (e.g. hydraulic) IWsT completion equipment. Mature, land field developments with limited reserves and low-rate wells or offshore platforms with easy well access have now become potential IWsT value opportunities, widening the market for this technology, driving the cost down further.

Generic screening parameters. Fig. 3 is part of a checklist developed using generic screening parameters for suitability of IWsTs.

|

Fig. 3. Generic reservoir screening parameters.

|

|

GEOLOGICAL RESERVOIR TYPES SUITED TO IWST

A methodology for identifying generic reservoir types, where IWsT is the preferred technology, has been developed, Fig. 4. The aim is to evaluate the interaction of intelligent completion with various geological models. Generic geological models have been constructed and were used in a systematic manner to study the impact of geological heterogeneities on recovery. The parameters were used to identify an added value from an IWsT envelope that was tested by choosing parameters within (and without) the envelope.

|

Fig. 4. IWsT Added Value Envelope (top) and how the “Added Value” is impacted by selection of reservoir parameters within the envelope (bottom).

|

|

An optimization technique is required to maximize the production and take advantage of the flexibility offered by ICVs. Examples studied include testing the following three optimization techniques on a real field case using:

- A reactive optimization technique (responding to the breakthrough of unwanted water or gas at the wellbore)

- A complete reservoir/ well system optimization with sensors that can image the flood fronts between the wells while managing the well injection and off-take profile

- An optimization model capable of predicting the well’s behavior.

ECONOMIC EVALUATION

IWsT has the potential capability to accelerate hydrocarbon production, and increase and extend the plateau, Fig 5. The value of implementing IWsT is the difference in Net Present Value (NPV) of the incremental (oil) revenue and the incremental costs resulting from IWsT installation. The required calculations are relatively complex, and some of the input data required contain a large uncertainty in their values. Deterministic NPV analysis underestimates the value associated with the technology. For example, how can an adequate description of geological complexity and risk be included? A further problem with the IWsT value calculation is that it has deterministic costs but a probabilistic income.

|

Fig. 5. IWsT has the potential to increase project by accelerating hydrocarbon production, increasing and extending the plateau, decreasing the decline rate.

|

|

Several methods are available to evaluate the techno-economic issues surrounding IWsT. One example is to identify potential value generation through greater oil production, reduced volumes of co-produced water and reduced uncertainty in the production profile. However, the magnitude of the value actually achieved is dependent on the functionality and reliability of the completion equipment, increased operating efficiencies due to reduced intervention, and, hence, deferred capital expenses. Inputs to consider in the evaluation process are summarized in Fig. 6.

|

Fig. 6. IWsT Economic Valuation Variables.

|

|

Software has been developed to quantify the stochastic added value of both ICVs and sensors. Hardware and sensor survivability profiles are captured via the Weibull function.

RESERVOIR/ WELL MODELING AND OPTIMIZATION TOOLS

It is important to be able to model and predict well performance and the interaction of these complex completions with the reservoir to quantify the added value. Experience has been built up, and techniques developed, using commercially available reservoir and well modelling and optimization tools. These have been tested in generic studies and with history-matched real, full-field and sector reservoir simulation models.

FIELD CASE STUDIES COMPLETED

Based on sponsor data, five field cases have been completed, ranging from single well cases to a multi-well study with the production and injection wells employing IWsT, Fig. 7. The single-well cases include production from stacked gas sands, where zonal allocation is the issue; intelligent and multilateral wells to manage production from a thin oil column; and complex geology and fluid properties (a rich gas condensate). These studies concluded with an economic benefit analysis for IWsT based on the production constraints associated with the real-field case.

|

Fig. 7. Multi-well IWsT added value.

|

|

| TABLE 1. IWsT aids gas output from stacked sands |

|

|

The potential value of automatic optimization of a multi-well field case, using a commercial optimizer, has been calculated. This approach proved valuable when building a value statement for the implementation of IWsT. Other optimization techniques are also being researched. The benefit of using IWsT completions in producing a stacked gas sands reservoir was analyzed for an environment, where commingled flow without downhole flow control was not allowed. I-Well accelerated production through commingling the flow, increasing recovery significantly, Table 1.

| TABLE 2. Total oil production |

|

|

Rapid gas breakthrough resulted in a conventional, horizontal well located immediately under the gas cap. It reached the gas output constraint after 2.5 years of production. IWsT control extended the well’s life and increased oil recovery. Multi-lateral wells extended the well’s life by distributing the production rate drawdown between the laterals. However, it is known that random zones of high permeability are sparsely distributed throughout the reservoir; hence ICV control at the mouth of each lateral is likely to be justified, to manage for this geological uncertainty, Table 2. As the data show, conventional wells are no match for advanced well architecture.

IWST VALUE FOR OILFIELD SCALE MANAGEMENT

This is an example of one of the many IWsT applications for well treatments. The completion design and some of the issues that may affect the production tubing performance, such as sand accumulation, are illustrated in Fig. 8. This case illustrates how access to downhole information improves the ability to deliver flow assurance in a real Brent group reservoir situated in the Norwegian sector of the North Sea that is produced by five production wells.

|

Fig. 8. Problems that affect completion performance in an IWsT.

|

|

The field is a highly under-saturated, geologically complex reservoir. Seawater is injected to support reservoir pressure, so a moderate barium sulphate scaling risk was assumed. IWsT production wells with variable ICVs were installed. The study showed that:

- ICVs could be used to shut off the potentially scaling zone, rather than closing the complete well while waiting for the scale inhibitor squeeze treatment to be carried out

- Reconfiguring the downhole completion with ICVs during the scale inhibitor provides more effective, more economical inhibitor placement

- Use of intelligent wells reduced the scale inhibitor requirement by 38%, i.e. a $24 million saving at a treatment cost of US$0.17/bbl of water produced, while decreasing the likelihood that the wells will suffer from scaling.

FINAL WORD

Details of this project can be found by visiting http://www.pet.hw.ac.uk/research/iwst or by contacting: david.davies@pet.hw.ac.uk for the current sponsor list and other project details.

|

THE AUTHOR

|

|

Dr. David Davies has been a senior lecturer in Production Technology at Heriot Watt University’s Institute of Petroleum Engineering for 10 years. He is also project leader of the industry JIP, “Added value from Intelligent Well systems Technology.” He has a first degree in chemistry from Exeter University and a PhD in Theoretical and Experimental Chemical Physics from the same university. Dr. Davies’ initial experience was four years with Shell Chemical UK Ltd., where he was involved in process control and the solution of chemical engineering problems. He then spent the next 22 years with Shell Exploration & Production, working in Technology Development and Application, and leading theoretical and experimental groups in virtually all areas of drilling and production operations. Three of these years were spent in Brunei as a senior engineer, for drilling and production.

|

|

|