Completions/ Stimulation Technology

Proppants raise the curve for coalbed methane production

Adding proppant in targeted completions can improve well profitability, according to public data from 100 wells in Alberta’s Horseshoe Canyon coalbed methane field.

Brad Rieb, BJ Services Company Canada Ltd., Calgary

As North American demand for natural gas rises, resulting in higher prices, unconventional gas resources become more economically attractive. This is driving the exploitation of coalbed methane fields.

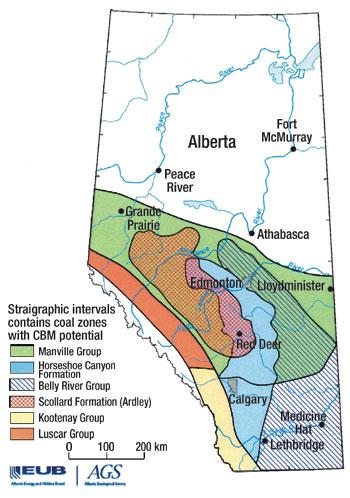

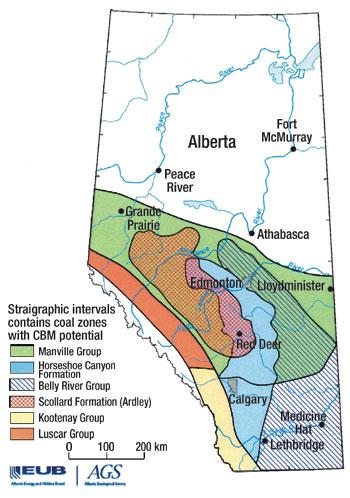

Drilling for coalbed methane in Alberta, Canada’s gas-prone basin (Fig. 1) has grown rapidly in the last two years, from 710 wells drilled in 2003, to 3,000 in 2005, and 3,500 wells projected for 2006. Most of this activity involves exploiting the pervasive, multiple seams of shallow coal beds. These gas-bearing coals are generally referred to as the Horseshoe Canyon family of geological formations. The Alberta Geological Survey estimates these formations contain more than 185 Tcf (5.2 Tm3) of dry, sweet methane.

|

Fig. 1. Horseshoe Canyon coals in Alberta, Canada, are a fast-growing target for gas well drilling.

|

|

A recent report estimates only 5% of Alberta’s coalbed methane resources (26 Tcf or 0.73 Tm3) are recoverable.1 Current reserve analysis suggests that recoverable, marketable reserves in the Horseshoe Canyon have significant variability and recovery factors range from as low as 10% to as high as 60% in some areas. Clearly, this low recoverability indicates a huge potential to increase recovery using advances in reservoir characterization and completion technologies.

Horseshoe Canyon wells are typically shallow (490 to 2,800 ft/150 to 850 m), which makes them quick to drill and readily accessible, but they are only marginally productive compared with conventional gas reserves.

Production varies considerably as wells commingle gas from up to 30 coal seams, each measuring 1.5 to 5 ft thick, with occasional seams up to about 10 ft (3 m) thick. Total wellbore production ranges from 35 to 635 Mcfgd (1 to 18 Mm3/d), with an average around 115 Mcfgd, or just under 42 MMcf/yr. With gas prices at $7/Mcf, that amounts to average annual gross revenues of about $295,000.

Rising gas prices have prompted a flurry of coalbed drilling activity, largely followed by status quo, proppantless completions. However, a recent study of coalbed methane wells completed in Horseshoe Canyon intervals suggests that including proppants during completion/ stimulation can significantly improve production.

COMPLETION AND STIMULATION

Completions in coalbed methane wells have historically run the gamut of completion techniques and hydraulic fracturing fluid systems. Because of their ultra-low water saturation and desiccated nature, the Horseshoe Canyon coalbed formations require dry, non-aqueous fracturing systems. This facilitates quick cleanup and evaluation, complete formation compatibility and easy treatment operations.

Historically, well completions in the study area employ three general strategies:

- Perforations targeting only coal seams, with a concentrated effort to contain fractures within the coal, Fig. 2a.

- Perforations targeting sandstone, with fracture growth expected in adjacent or nearby coal seams, Fig. 2b.

- Perforations covering both sandstone and coal, with fracture growth possible, Fig. 2c.

To evaluate these completion strategies and better understand reservoir production characteristics, BJ Services Company Canada analyzed public completion and production data for 98 wells completed in Horseshoe Canyon coalbed intervals northeast of the city of Red Deer in central Alberta, Canada.

In this area, standard industry practice is to complete all coal seams identified by neutron-porosity cased-hole log response. Therefore, typical wells can include 10 to 30 potential gas-bearing targets. The most common completion technique has been sequentially stimulating each coal seam with high-rate nitrogen (and no proppant), using a simple coiled tubing cup tool assembly to isolate each seam for treatment, Fig. 3.

|

Fig. 3. The most common completion technique for Horseshoe Canyon coal seams is sequentially stimulating each seam through coiled tubing.

|

|

Because no proppant is involved, these treatments never run the risk of sanding off, eliminating the risk of a wellbore clean-out operation. Furthermore, the extensive wellbore stimulation of these discrete multiple coals allows the operator to immediately assign volumetric reserves to each completed zone. However, they do have some significant technical pitfalls.

First, high-rate nitrogen stimulation depends upon developing adequate net pressure at the coal face and in the cleat system to create fracture width and length. Inherent nitrogen gas characteristics of compressibility and extremely high leak-off make it difficult to achieve sufficient net pressure to affect poorly developed cleat systems, such as those found in Horseshoe Canyon coals. Additionally, because of the required high treatment rates, erosion will promote coal fines generation that can impede production.

Second, because the treatment does not use proppant, its success relies on residual permeability created when high-rate nitrogen at high pressure disrupts the naturally closed cleat face and structure. This tendency further complicates an effective stimulation, since most of central Alberta’s coals are in compressional stress, so, stimulation without proppants can result in rapid closure of the cleat system.2

A possible alternative to this completion strategy is the use of conventional or lightweight proppants with fracture fluid systems that are completely compatible with coal. This option exploits the long-understood and much publicized benefits of fracture sand conductivity in fracture stimulation.

The downside of this option is the relatively higher cost of transporting proppant (compared with pumping N2 only) into 10 to 30 coal seams. Grading seams by their likely gas production would enable a more cost-effective completion strategy, reducing costs by targeting only high-graded intervals. This option trades the booking of volumetric reserves against improving long-term permeability in a few high-graded coal seams.

The key to designing a stimulation plan, then, is to learn more about the producing mechanisms of coalbed methane.

COAL AND SANDSTONE

In a pilot study of Horseshoe Canyon wells,3 we examined completion and production data for 37 wells whose completion technique include coal seams (i.e., resembling Figs. 2a or 2c). Fracture stimulations on these wells included proppantless N2, 80% N2/20% CO2 with proppant, and water/ methanol CO2 emulsion systems with proppant.

The data showed that wells completed with water/ methanol/ CO2 systems produced much less gas than the other wells, possibly because of their high (80% or more) CO2 volumes. One issue with using CO2 in this region is that the dry coals adsorb pure (100%) CO2, impeding methane production. Reducing the percentage of CO2 in a mixture significantly reduces the problem, but the benefits require reductions to 25% CO2 or less.4,5 The initial study also indicated that sandstone might contribute to production from some N2-stimulated wells originally believed to have been stimulated only in coal seams. Although all wells in the pilot study included coal seams in their perforations, many also had perforations in neighboring gas-bearing sandstone.

These findings prompted an expanded study, including wells whose perforations do not cover coal seams but whose fracture stimulations might have fortuitously reached those coal seams (and their captive gas) through fracture-height growth.

Under normal fracturing pressures, fracture-height growth has been known to reach coal zones 15 ft from the perforations. Radioactive tracers have indicated that height growth, although uncommon, can develop to 30 ft. The role of ineffective zonal segregation (from poor drilling and cementing practices) on these results is unclear. Additionally, the complex lithology of coal, shale, siltstones and sandstone will affect fracture dimensions.

Based on this understanding of fracture growth, we examined production data from wells with proppantless N2 fractures in coal, and those with CO2/ N2 proppant stimulations whose perforations were within 10 m of coal seams, Fig. 4.

|

Fig. 4. First-year production data for wells with Horseshoe Canyon coal seams show higher average production from proppant-stimulated wells than from proppantless completions. See Fig. 5 legend.

|

|

PROPPANT ADVANTAGE

The proppantless N2 fracture stimulations targeted dry coal seams in the well, using coiled tubing to deliver that treatment to, typically, 10 to 30 perforated seams. The CO2/ N2 propped fracture stimulations targeted one to three high-graded zones and used conventional completion techniques of wireline perforating and bridge plugs to segregate targeted intervals.

Although they produce from fewer zones, the high-graded CO2/ N2/ proppant completions produce more gas in total, on average, than the proppantless N2-only wells. The propped wells come online with average initial production at 177 Mcfgd (5 Mm3/ d) compared with unpropped wells at 141 Mcfgd (4 Mm3/ d), then both types of wells decline with similar slopes and stabilize to constant rates within 7,000 hr, as expected for coal-dominated production. Throughout this production decline, CO2/ N2 propped stimulations continued to produce at a significant premium over those completed with only N2.

Over the course of a year, the in-coal CO2/ N2/ proppant-stimulated wells produce an average of 54 MMcf (1,530 Mm3), 23% more gas than the 44 MMcf (1,245 Mm3) average from the proppantless wells. Thus at $7/Mcf, the average proppant-stimulated well produced $70,000 more gross revenue in a year than the average proppantless well – and the total stimulation cost was $15,000 less.

Production data for wells whose perforations are 5 or 10 m away from coal seams show higher initial production followed by a steep transient production decline and late-time stabilization: classic characteristics of tight sandstone-dominated production.

The production data also clearly show the effects of water migration into sandstone intervals in these low-pressure reservoirs. Average daily production of wells stimulated as far as 10 m from a coal seam shows higher initial production than in-coal stimulations, but around 6,000 hr of production time, production falls below the average for wells whose completions targeted coal seams.

Still, a high-graded combination of coal with sandstone can increase production and operator profit, especially if the stimulation treatment plan avoids areas likely to induce water production. An average well stimulated with CO2/ N2/ proppant within 5 m of a coal seam yielded $15,000 in stimulation savings and incremental production valued at $189,000 per well after one year, compared with the average proppantless stimulated well, Fig. 5. Incremental production over a propped well with stimulation confined to the coal seam is about $119,000. Clearly, the benefit of proppant and conductivity translates itself into profit.

|

Fig. 5. At the end of a year, proppant-stimulated wells produced as much as 50% more gas than those treated with N2 alone.

|

|

After reviewing these data, we decided to take the data analysis one step further. To account for individual reservoir variations, we normalized well production rates to gross pay (perforated pay for the in-coal stimulations and a best estimate of total stimulated pay for the sandstone-dominated stimulations). The general character and shape of the daily and cumulative production graphs correlated directly to the figures included here.

ACTING ON THE RESULTS

These wells are expected to continue stable (if low-rate) production for 20 to 40 years. Because Alberta’s coalbed methane reserves have only recently gained widespread interest as a production and exploitation target, the long-term impact of proppant versus proppantless completions has yet to be fully understood.

However, anecdotal evidence appears to support the theory that proppant fracturing results in improved production. Two years after stimulating multiple coal seams with proppantless N2 systems, some operators have shared post-completion flowmeter surveys indicating poor to non-existent gas production from some stimulated coal seams – including the thickest seams that had been expected to produce the most gas!

In some regions of the development fairway, operators have voiced the concerns that only 20% of the perforated and "stimulated" zones are producing gas. This could mean that up to 80% of the completed zones are under-stimulated or incorrectly characterized.

In our experience, the over-used term "skin damage" is becoming a catch-all for a host of complex flow dynamics including reservoir pressure, flow capacity and ineffective stimulation. This frustration has motivated some operators to pursue detailed reservoir characterization through unique petrophysical analysis and post-treatment production profiling.

Based on our data analysis and experience, and these anecdotes, we developed a stimulation treatment plan for three wells that were to be completed in the Horseshoe Canyon coals. In each well, we used CO2/ N2 proppant treatments to sequentially fracture three high-graded zones through coiled tubing. Although production data were being held confidential, the results from the first 100 days of production are very encouraging.

As a further step toward optimizing completion techniques for these coals, BJ has developed a proprietary technique of combining conventional and ultra-lightweight proppants in a high-rate N2 gas stream, with or without CO2. The company has completed operational trials, and field applications are pending.

LITERATURE CITED

1 Canadian Gas Potential Committee, "Natural gas potential in Canada – 2005," May 2006.

2 BJ Services Company Canada Ltd. and Rakhit Petroleum Consulting Ltd., Joint Venture, "Multi-client study: Stress analysis – Central Alberta," January 2006.

3 Rieb, B. A., and T. T. Leshchyshyn, "The production success of proppant stimulation on Horseshoe Canyon coal bed methane and sandstone commingled wells," SPE 96864, presented at SPE Annual Technical Conference and Exhibition, Dallas, October 2005.

4 Mavor, M. J. and W. D. Gunter, "Secondary porosity and permeability of coal vs. gas composition and pressure," SPE 90255, presented at SPE Annual Technical Conference and Exhibition, Houston, September 2004.

5 Mavor, M. J. and W. D. Gunter, "Alberta Multiwell micro-pilot testing of CBM properties, enhanced methane recovery and CO2 storage potential," SPE 90256, presented at SPE Annual Technical Conference and Exhibition, Houston, September 2004.

|

THE AUTHOR

|

|

Brad Rieb, P. Eng., is the regional technical manager for BJ Services Company Canada, Ltd., in Calgary, Alberta, Canada. He earned a diploma in Petroleum Technology from the Southern Alberta Institute of Technology in 1979 and a BSc in Petroleum Engineering from Montana Tech of the University of Montana in 1982. He has held senior technical roles in production, completion, reservoir engineering and business development. Mr. Rieb is a registered professional engineer in the Province of Alberta and a member of SPE.

|

|

|