New Bit Designs

Smith Tool/Smith Bits

Adaptive design maximizes hydraulic efficiency

As rock bit design becomes increasingly sophisticated, the ability to maximize the bit's hydraulic efficiency is critical to obtaining peak performance. Smith Tool addresses this issue with the Flex-Flo Adaptive Hydraulic Design system. Flex-Flo uses three separate hydraulic configurations to deal with formation types that range from very soft and/or sticky to extremely hard and abrasive. Multiple choices of nozzle length, nozzle diameter distribution and fluid jet trajectories on a hydraulically efficient body provide flexibility in flow regimes.

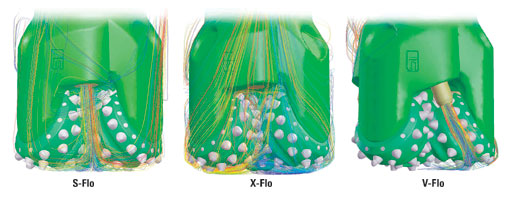

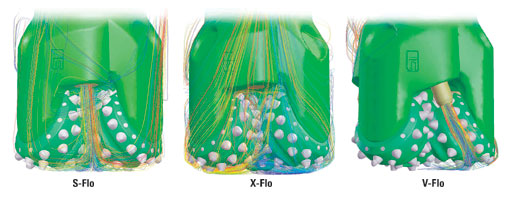

The three Flex-Flo configurations allow bits to be specifically tailored to the application in order to maximize hydraulic efficiency:

- S-Flo uses three similarly sized nozzles in a variety of lengths directed at the bottom of the hole;

- X-Flo has asymmetric, or significantly dissimilar, nozzle areas in a variety of available lengths directed at the bottom of the hole;

- V-Flo directs flow toward the leading side of the cones, typically using similar sized nozzles of various lengths.

|

To maximize the hydraulic efficiency of a rock bit, the Flex Flo system uses three hydraulic configurations (left to right), S-Flo, X-Flo and V-Flo.

|

|

Bit balling, the result of inadequate cleaning, causes premature cutting structure wear and limits penetration rate. Inefficient removal of the rock particles means that the bit's cutting structure must penetrate existing cuttings before it can drill new formation. Ideally, cuttings would be carried away from the bit in a uniform method, but the downhole reality is that there are regions of different flow velocity, dead zones where fluid energy is low, and recirculation zones where cuttings seem to “hover.” Flex-Flo helps select from a range of nozzle combinations and orientations to optimize the fluid system in each drilling environment.

|