Handheld computer system reduces costs and increases data value

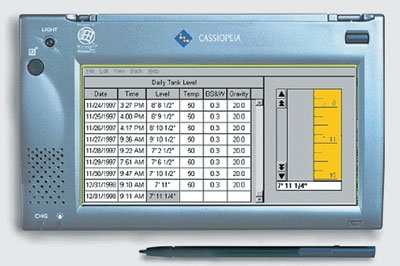

Handheld computer system reduces costs and increases data valueScott Daves, Markwest Resources, Englewood, Colo., and Wayne White,* IHS Energy Group, Englewood, Colo. Bottom line. Markwest Resources implemented IHS Energy’s FieldDIRECT field data collection system using Windows-based handheld personal computers and quickly realized cost savings through more efficient use of field personnel’s time. One-time data entry with access to current field data improved management decisions and realized efficiencies company-wide. Problem addressed. Like many companies, Markwest adds properties through acquisitions without proportionally adding people. This significantly impacts field operations. Production specialists collect daily production data using the standard seven-day gauge sheets, which requires filling out forms, plus 30- to 60-min. drive times to the office for faxing the reports. Data collection with handheld computers. Following a thorough investigation of the alternatives for low-cost electronic collection of field data, Markwest implemented IHS Energy’s Windows CE-based handheld computer system. Data is transferred by modem daily to a central web-based server and made available to anyone with the proper password through the Internet. Markwest selected a handheld computer made by Casio. Field personnel average less than 1 hr per day performing data entry. This device includes a black and white LCD screen that is easy to read in the sunlight. The device is 7 in. by 4 in. and has a large screen for the production specialist to see several days’ worth of data, Fig. 1. A full 30 days of data is stored in the device on a compact flash card.

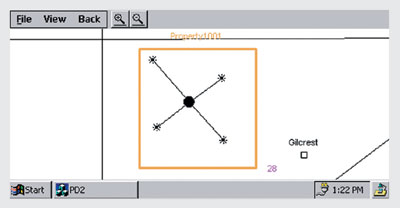

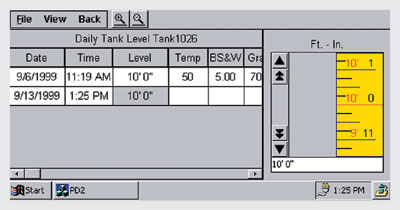

Properties were set up by IHS’s Customer Support Staff using an application called Builder. This application searches the 1.3 million wells in IHS Energy’s database for wells Markwest operates. After wells are located, wells, tanks and meters are graphically assigned to properties. All tanks, meters and wells are associated with production sites. Producing sites are associated with pumpers, foremen or other authorized users. These "routes" are available to anyone who accesses the system from one of the handheld computers. Once they sign-in, their "routes" are loaded onto the handheld computer. Typically, a production specialist gauges a tank or takes meter readings and then turns on the handheld computer. It displays a map of the specialist’s route or a list of all the wells and gathering points for which he or she is responsible. The production specialist uses a pen stylist to tap on a graphical representation of a tank / well / meter, Fig. 2. The screen changes to show a small spreadsheet of prior days data with the focus on the current date. The specialist taps on a cell to enter data and the appropriate graphical control is displayed, Fig. 3. If the value is a tank gauge, then a tape measure appears. The specialist then taps the screen on the tape measure that corresponds to the reading in feet and inches. A tap on the tank volume cell shows the amount of oil or water based on the tank strapping. Other values can be changed at this time (temperature, BS&W, gravity, etc). Many data fields do not change from day to day, so the values automatically carry forward. After all data fields are entered, the specialist taps on the Back button to return to the map or list. The handheld computer can be turned off, or if let alone, shuts off automatically.

Database management system. The system consists of a web-based central database managed by IHS Energy. Field data is sent daily through normal phone lines via an 800 number to the database. Data is entered into the system by a handheld computer, the keypad of a phone, or through an Internet interface. Production is allocated based on well tests in the central database and is immediately available for viewing through a Windows-based application called Production Explorer. This application allows staff to view daily production plots, as well as plots of values coming directly from tanks, meters and well tests. There are a number of production and test reports available. The pivot table feature displays production data in customized groupings. For example, summary or average production for each completion for the last week of the last month can be viewed. Production data and/or the pivot data can be copied quickly into common office applications. Users immediately see well-by-well and compressor trends, either on the handheld PC or an office PC. Graphs provide immediate feedback. Keeping a "pickup notebook" of hand-written reports is no longer necessary. The system eliminates the frustrations of faxing data or return trips to the office if the transmission was faulty. Production data is entered once and is available to everyone thereafter. This immediate pass-down of information has beneficial ripple effects throughout the company. Data can be posted on the Internet so that anyone can see, use or zip it to send electronically to outside customers or contractors, such as reserve reporting. More accurate and timely management decisions are made, since daily production is available immediately. Information flows seamlessly throughout Markwest – even the accountants can prepare accruals with a minimum of waiting for prior-months’ totals. The system saves time and energy. For example, the first day of viewing data in Markwest’s office coincided with a call from field personnel asking for advice on the location of a needed water-transfer pump. A quick review of the data indicated that the pump was to be installed at a different location. This decision required just a few minutes, but saved hundreds of dollars. The gas nomination process now is much more effective with the use of daily field data, thereby minimizing the potential for contractual gathering and transportation penalties. Monthly reporting from the production department to the accounting group has reduced the production technician’s workload from 3 to 4 days to about 3 hours per month. Economic benefits. The service costs $10 per well per month. This fee includes everything from support to 800 numbers and the service of the database. All that is needed to begin is the purchase or lease of handheld computers and the installation of Production Explorer. The investment was justified on the savings realized in the field operations based on effective decisions and increased production. Just as field operations benefit, office personnel that use the data for technical evaluations and reporting achieve significant benefits and efficiencies. This solution did not require a large investment in an internal database and hardware, or require additional people with skills to manage the system. PTD

|

|||||||||||||||||||||||||||||

- What's new in production (February 2024)

- Prices and governmental policies combine to stymie Canadian upstream growth (February 2024)

- U.S. operators reduce activity as crude prices plunge (February 2024)

- U.S. producing gas wells increase despite low prices (February 2024)

- U.S. drilling: More of the same expected (February 2024)

- U.S. oil and natural gas production hits record highs (February 2024)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)