Advances in MWD and formation evaluation for 2002

MWD/Formation EvaluationAdvances in MWD and formation evaluation for 2002Developments include well log scanner; wireline, memory and while-drilling logging methods; mud-log gas measuring system; and open- and cased-hole wireline test toolsDavid Patrick Murphy, Shell Technology EP, Houston The latest advances in formation evaluation, especially data acquisition while drilling, are improving quality and increasing the quantity of formation data, while reducing costs and making operations more efficient. Some of these recent advances discussed in the following presentation include:

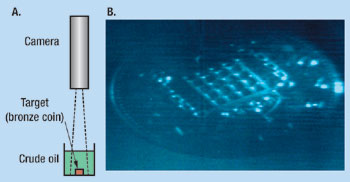

Wireline Logs Wireline logs typically provide more formation evaluation wellbore data for lower cost than other tools, except when rig costs are very high. Seven applications are discussed here. Microresistivity imaging. Computalog’s new Electric Micro Imager (EMI) provides high-resolution resistivity formation imaging.1 Applications include fracture identification / analysis, secondary porosity identification, thin-bed delineation and dip / structural analysis. EMI is based on Computalog’s Six Electrode Dipmeter technology utilizing six articulated pads, each mounted on an independent arm. The six pads contain a total of 150 calibrated microresistivity sensors which provide 63% circumferential coverage in a 200-m (7-7/8-in.) borehole. Detailed borehole-wall resistivity images are obtained by sampling each microresistivity sensor every 0.1 in. (2.5 mm) along the borehole length. EMI navigation data is acquired by three orthogonal fluxgate accelerometers and three orthogonal magnetometers providing tool position, motion, direction and orientation information. A speed-correction algorithm – using high-rate accelerometer measurements along the borehole axis – reduces image artifacts that occur when actual tool motion does not match uphole-measured wireline cable velocity. Optical imaging. In a feasibility study, Proneta Ltd. has applied aerospace industry technology to demonstrate high-resolution optical imaging through crude oil.2 In the lab, it was able to produce high-resolution images of a coin face contained in a beaker below about 4 in. of crude, Fig. 1. Proneta is currently developing a prototype wireline tool in a joint industry project (JIP) sponsored by Amerada Hess, BP, Chevron and Shell. The development will be in two phases: 1) construct a lab imager to work with real targets, e.g., damaged downhole equipment; and 2) re-package the prototype imager to operate in a downhole environment. The prototype imager will then be deployed for downhole trials in well-workover operations.

NMR fluid characterization. Schlumberger has introduced a new magnetic resonance fluid (MRF) multifluid-relaxation model to apply to field data acquired by a nuclear magnetic resonance (NMR) well logging tool.3 By simultaneous inversion of a suite of NMR data, the MRF method provides a detailed formation evaluation of the near-borehole region investigated by modern NMR logging tools, including:

*Even when brine and oil T2 distributions completely overlap each other. The MRF method is currently undergoing worldwide experimental field testing. Combinable Magnetic Resonance (CMR) tools operating in station mode are being used to acquire suites of MRF data. Station depths are selected by using CMR and other openhole logs to identify potential zones of interest. Directional permeability. An understanding of reservoir directional permeability anisotropy is pertinent information for the reservoir simulator. Joanneum Research and Baker Atlas have published their theoretical- and real-data permeability anisotropy computation, using multi-component induction resistivity data available from Baker Atlas’s 3D Explorer (3DEX) logging tool.4 Archie and Coates equations provide a simple petrophysical connection between resistivity anisotropy and permeability anisotropy, both of which are scale dependent. Joanneum and Baker Atlas also found that NMR-derived permeability data can be converted to vertical and horizontal permeabilities for finely layered anisotropic sands composed of layers of different grain sizes, porosity and/or sorting. It was necessary to use NMR T2 distribution data to determine fine- and course-volume fractions to partition porosity and bulk volume irreducible (BVI) between vertical and horizontal components. Permanent formation resistivity monitoring. Team Energy and Schlumberger have documented the first successful installation, testing and interpretation of measurements made by cemented-resistivity arrays in a producing oil field.5 Their experiment, begun during 1999, has established the feasibility of using cemented-resistivity arrays to monitor waterflooding. The effort demonstrated the following:

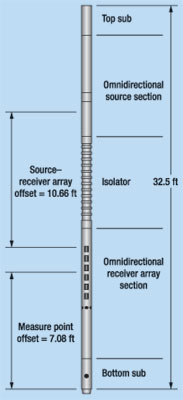

The main advantage of permanent sensors is that the fixed location of the voltage sensors enables detection of very small changes in fluid-front positions through analyses of differences in voltages between successive data-acquisition cycles. Spectral gamma ray. Lamont-Doherty Earth Observatory of Columbia University has developed a high-vertical-resolution, Multi-sensor spectral Gamma-ray Tool (MGT) for the Ocean Drilling Program.6 The aim and purpose is to: enhance vertical resolution over conventional logging tools; allow for finer resolution of thin-bed zones; provide better correlation among different logging runs; and improve comparison to core measurements. MGT uses an array of independent, self-contained gamma spectrometry modules with 2-ft spacing. Each module comprises an NaI detector, a programmable amplitude analyzer, and an individual spectrum stabilization system. The tool also includes an accelerometer to improve data stacking in real time using logging speed measurements. Results from MGT field testing achieved vertical resolution three to four times better than conventional logging tools, with equal counting effectiveness at common logging speeds. Well tractor. Smedvig is testing a prototype well-tractor pulling device, the Bulldozer, designed and manufactured by AaTechnology.7,8 This electromechanical device has a larva-like characteristic; it adjusts itself to shape and dimension of the available space using the entire radius in the pipe for grasping; and it can operate in diameters exceeding 50% of tool OD. The developer’s aim is to apply this tool in both open and cased hole for transport of equipment for: cleaning operations; setting and removing plugs; opening / closing sliding sleeves; and well logging. MWD Measurement-while-drilling formation-evaluation-tool suites are providing additional measurements, more accurate versions of existing measurements, and new deployment / telemetry options. Examples of five relevant technology developments are presented below. Acoustic log. Baker Hughes INTEQ has introduced its Acoustic Properties eXplorer (APX), while-drilling sonic logging tool, Fig. 2.9 APX is designed to provide quality acoustic slowness measurements in noisy drilling environments by applying the following attributes:

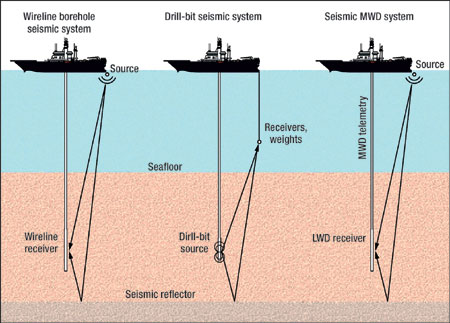

Seismic while drilling. Schlumberger has introduced SeismicMWD, a new technique which provides conventional borehole seismic measurements while a well is being drilled.10,11 Applications include locating the drill bit in seismic space, predicting pore pressure in undercompacted depositional environments, predicting target depth, and optimal landing of the well in a reservoir. The SeismicMWD system comprises an LWD tool with seismic sensors in the bottomhole assembly, a seismic source with control equipment at the surface, and an MWD system for real-time telemetry to surface, Fig. 3.12

The seismic energy is produced from a conventional source such as an air gun. Offshore, the source can be deployed from the rig or a boat for offset surveys. The seismic source is fired during pipe connections; seismic data is processed downhole; and check-shot information – time it takes the seismic wave to travel from surface to downhole tool – is transmitted to surface. All seismic data is recorded in downhole memory for further processing. SeismicMWD development’s initial focus is the check-shot measurement to obtain time-depth relation for locating the drill bit in seismic space. Nuclear magnetic resonance. NUMAR Halliburton has developed and commercialized its second-generation Magnetic Resonance Image-Logging While Drilling (MRI-LWD) tool.13 MRI-LWD operates in two modes:

MRI-LWD improvements include automatic mode switching, better vertical resolution, improved signal-to-noise ratio, real-time data transfer, built-in log quality control, increased battery life and extended environmental ratings. Wired composite tubing telemetry. Halliburton has introduced Anaconda Advanced Well Construction System.14 Anaconda’s digitally-controlled system uses a carbon-filler composite umbilical tubing with embedded conductors, called SmartPipe, and a downhole advanced Drilling, Evaluation and Propulsion Tool (ADEPT) assembly. SmartPipe’s embedded conductors provide the ability to transmit electrical power down to the tools and relay two-way data between surface and subsurface. Telemetry rate for the real-time data is several thousand times greater than is currently achievable with other commercial, while-drilling telemetries. Anaconda surface equipment includes a control center, SmartPipe injector and reel, a tower and pipe-handling system, blowout preventers, and a digital control and data-acquisition system. Fiber-optic telemetry. Sandia National Laboratories has developed and tested a disposable fiber-optics telemetry system for MWD.15 The fiber-optics cable is inexpensive and small enough to be used for a short time, then ground up and flushed out in the drilling mud. Operational tests at a Gas Technology Institute (GTI) facility were successful to depths of 3,000 ft, but Sandia does not expect any depth limitations. The researchers determined that the fiber-optic telemetry could transmit data at about one megabit per second, about five orders of magnitude greater than other commercial, while-drilling telemetries. Early research funding came from Sandia’s Laboratory Directed Research and Development program, while GTI has funded more recent research. Wireline Testing Formation testing provides pressure and fluid information. Three new developments described here illustrate tools for cased- and open-hole applications. Cased-hole tester. Schlumberger has introduced Cased Hole Dynamics Tester (CHDT), developed with support from Gas Technology Institute (GTI).16 CHDT has the unique ability to drill a small hole through casing / cement into the formation, perform multiple pressure measurements, recover fluid samples, and then plug the hole in the casing. The corrosion-resistant plug provides a metal-to-metal seal rated to a differential pressure of 10,000 psi. This 4.25-in.-dia. tool can be run in casing sizes ranging from 5-1/2 to 9-5/8 in. Up to six depths can be tested in one trip into the well. One-gallon, H2S-rated sample chambers, suitable for standard 5-1/2-in. casing, are available. Additional CHDT-compatible sample chambers are also available for operations in 7-in. casing, or larger. They include the multisample module with six 450-cc bottles; 250-cc single-phase multisample chambers; and 1-, 2-3/4-, and 6-gal sample chambers. Several chambers can be run simultaneously. CHDT is combinable with Schlumberger’s modular Formation Dynamics Tester (MDT) modules such as the Optical Fluid Analyzer (OFA). CHDT can also be combined with other through-casing formation evaluation tools such as the Cased Hole Formation Resistivity Tool (CHFR) and Reservoir Saturation Tool (RSTPro). NMR fluid analyzer. NUMAR Halliburton has developed a nuclear magnetic resonance (NMR) downhole-fluid analyzer, compatible with its Reservoir Description Tool (RDT) modular formation sampler and tester, Fig. 4.17 T1 relaxation times and hydrogen density (automatically converted to hydrogen index) can be measured continuously, whether the fluid is stagnant or flowing. This mode is most useful during the pump-out period to assess the amount of mud filtrate contamination. T2 relaxation times cannot be determined on a flowing sample, but are measured on samples that have been momentarily stagnated. Stagnation is achieved by closing a valve below the analyzer and diverting the flowstream around the sample chamber. The required stagnation time for a T2 measurement is almost entirely determined by the polarization time (or wait time) of 15 sec.

Operating at 4 MHz, the downhole-fluid analyzer provides near-laboratory, signal-to-noise ratios and operating speeds. And, the resonance frequency is still close enough to that of NUMAR’s wireline (MRIL) and LWD (MRIL-WD) tools to provide hydrogen index values for porosity correction, and to differentiate between mud filtrate and formation fluids in the measurement space of these logging tools. Compact pressure tester. Reeves Wireline Compact Repeat Formation Pressure Tester (MFT) is a 2-3/4-in.-dia. tool which can pass through restrictions as small as 3 in., Fig. 5.18 MFT is rated to 125°C and 12.5 kpsi. It can measure pressures in hole sizes from 3-7/8 to 11 in. This 13.3-ft-long tool only weighs 112 lb. Its small size allows its use in wells which have access restrictions due to small diameter or high dogleg severity.

Memory Logs Slimhole, memory openhole logging tools are available using several types of conveyance, one of which is discussed here. Drill pipe conveyance. Reeves Wireline has commercialized its Compact Well Shuttle, which conveys Reeves’ compact openhole memory logs inside drill pipe, providing an alternative to drill-pipe-conveyed wireline logs in high-angle, extended-reach wells, or wells with bad hole conditions.19 When running in the hole, the Well Shuttle and logging tools are protected inside the drill pipe while being tripped to total depth. At TD, a pumpdown device called the Messenger is pumped down the drill pipe until it engages the Shuttle. Further pumping locks them together and forces the memory logging tools out of the Shuttle and into the open hole. There is positive indication at surface when successful landing and deployment of the memory logging tools has occurred. As the drillstring is pulled to surface, the well is logged. Operationally, well control is available and the drillstring can be rotated and reciprocated at all times. The Shuttle system recently completed a nine-month trial program in the Reeves Large Flow Loop facility and the horizontal test well at the company’s Downhole Technology Centre. The first Shuttle system is now operational in Canada, and service will be commenced in the U.S., Europe and Australasia during early 2002. Mud Logging Mud logging provides nearly-real-time information concerning lithology and hydrocarbon presence. Gas measurement. Geoservices’ Reserval Service provides a constant-volume gas trap directly at the bell nipple, and a second gas trap in the suction pit, with total-gas and chromatograph analysis.20 The constant-volume trap is unaffected by mud flow variations or solids accumulation. The second gas trap allows for analysis of recycled gas. Geoservices uses a five-point calibration for its total-gas and chromatograph analyzer. The chromatograph is fast (C1 to nC5 42 sec) with 1-ppm sensitivity. The aim is to provide a more consistent set of gas measurements for comparison of mud-log data from well to well. General The new portable well-log scanner described here allows digital data acquisition anywhere. Portable well-log scanner. Neuralog has introduced the NeuraScanner, portable well-log scanner.21 This 10-lb device can fit into a briefcase or laptop case for transportation to rig, data room, etc., Fig. 6. NeuraScanner attaches to a PC USB or serial port and, optionally, can be used as a log copier by scanning to a well-log printer. Log print widths up to 12-in. and unlimited length can be scanned. A removable lid allows convenient start / stop at any point along a log print. Once the paper log has been captured as a log-image file, the company’s NeuraLog digitizing software can be used to convert that image file to usable computer data in LAS or other digital-log formats.

Acknowledgment The author would like to thank Shell Technology Exploration and Production for permission to publish this article. The author gratefully appreciates technical details and insight provided by companies whose technology is discussed. Literature Cited 1 Computalog, Electrical Micro Imager (EMI), www.computalog.com, January 2002. 2 Hother, J., "Imaging through crude oil with high resolution, optically," SPE Annual Technical Conference and Exhibition, Transactions, October 2001. 3 Freedman, R., et al., "Field application of a new nuclear magnetic resonance fluid characterization method," SPE Annual Technical Conference and Exhibition, Transactions, October 2001. 4 Schon, J., et al., "Imparting direction dependence on log-derived permeability," SPE Annual Technical Conference and Exhibition, Transactions, October 2001. 5 Bryant, I., et al., "Utility and reliability of cemented resistivity arrays in monitoring waterflood of the Mansfield sandstone, Indiana, U.S.," SPE Annual Technical Conference and Exhibition, Transactions, October 2001. 6 Goldberg, D., et al., "High vertical resolution spectral gamma ray logging: A new tool development and field test results," SPWLA 42nd Annual Logging Symposium, Transactions, June 2001. 7 AaTechnology, News from AaTechnology, October 2001. 8 Smedvig, The Bulldozer – New generation well intervention device, October 2001. 9 Joyce, B., et al., "Introduction of a new omni-directional acoustic system for improved real-time LWD sonic logging – Tool design and field test results," SPWLA 42nd Annual Logging Symposium, Transactions, June 2001. 10 Schlumberger, SeismicMWD, Brochure SMP-4049, September 2001. 11 Esmersoy, C., et al., "Seismic measurement while drilling: Conventional borehole seismics on LWD," SPWLA 42nd Annual Logging Symposium, Transactions, June 2001. 12 Bratton, T., et al., "Avoiding drilling problems," Oilfield Review, Summer 2001. 13 Drack, E., et al., "Advances in LWD nuclear magnetic resonance," SPE Annual Technical Conference and Exhibition, Transactions, October 2001. 14 Halliburton, "Halliburton pioneers revolutionary drilling and intervention system," www.halliburton.com, May 2000. 15 Burroughs, C., "Inexpensive disposable fiber optics can relay real-time information about well-drilling process," Sandia Lab News, March 23, 2001. 16 Schlumberger, Cased hole dynamics tester, Brochure SMP-5681, September 2001. 17 Prammer, M., et al., "The downhole NMR fluid analyzer," SPWLA 42nd Annual Logging Symposium, Transactions, June 2001. 18 Reeves Wireline, "Compact repeat formation pressure tester," www.reeves-wireline.com, January 2002. 19 Reeves Wireline, "Compact well shuttle completes trials and enters commercial service," www.reeves-wireline.com, January 2001. 20 Geoservices, "The Reserval Service," www.geoservices.com, January 2002. 21 Neuralog, "NeuraScanner Portable Well Log Scanner," www.neuralog.com, January 2002

|

|||||||||||||||||||||||||

- Quantum computing and subsurface prediction (January 2024)

- Machine learning-assisted induced seismicity characterization of the Ellenburger formation, Midland basin (August 2023)

- What's new in exploration (March 2023)

- Seismic and its contribution to the energy transition (January 2023)

- What's New in Exploration: Rocks can save or kill the planet (July 2022)

- Processing of a large offshore 3DVSP DAS survey in a producing well (June 2022)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)