Using a new biological option to repair polymer-induced formation damage

Using a new biological option to repair polymer-induced formation damageScott Bailey,* Micro-Bac International, Inc.,

Round Rock, Texas, and

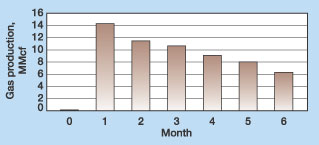

Stan Atnipp, SLA, Inc., Midland, Texas Bottom line. Treatments with biological stimulation fluids effectively repaired reservoir damage caused by polymer fluids in two wells. Production from a gas well in southwest Texas (which produced about 1,500 Mcf per month prior to being essentially shut-off by damage from copolymer fracturing fluids) initially increased to more than 14,000 Mcf per month after biological treatment. And, the well stabilized at about 3,000 Mcf per month six months later. A similar biological stimulation treatment to remove polymer damage in a West African oil well increased production more than 40%. Formation damage from polymer fluids. Hydraulic fracturing often is used in new completions, and favorable economics with today’s oil and gas prices have caused many producers to pursue re-stimulation programs in mature fields. However, hydraulic fracturing is an inexact science, with as many as 20% of treatments having unfavorable results. Both water and non-Newtonian fluids, such as complex polymers and gels, are used in hydraulic fracturing treatments. Polymers and gels often are the fluid of choice. Unfortunately, these gelling agents can cause formation damage. In many cases, when a well is blocked, it is simply abandoned. Treatment with biological stimulation fluids, applicable to both oil and gas wells, is a relatively new solution option for repairing formation damage caused by polymers. SLA, Inc., worked with an operator on a well in southwest Texas, which after an acid frac, did not produce back the polymer injected. Data also are presented for a West African oil well, in which polymer damage was identified as a suspected cause of reduced productivity. Micro-Bac’s engineering services group recommended treatments using their recently developed biological stimulation fluids to repair the suspected formation damage from polymer fluids. Gas well, southwest Texas. Prior to fracture stimulation, this well produced about 1.5 MMcf per month. After fracturing with a copolymer, the well (Fig. 1) would not produce. To repair damage caused by the polymer and restore productivity, the well was treated with a combination of biological stimulation products. The primary component was Gum-Bac, which is designed to break down the polymer base in the frac fluid and allow water to be removed from the formation in order to enhance production rates.

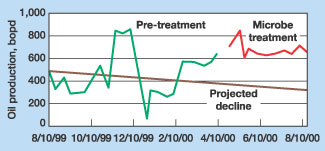

Additional biologicals were used to enhance overall treatment effectiveness. The treatment was done using 200 bbl of freshwater pumped at an average of 2 bpm at 1,000 psi. The well was shut in for 12 days after treatment to allow the microbes to migrate to the damage and break down the polymer in the near-wellbore region. After the shut-in, the well was opened and swabbed to recover enough fluid to allow it to commence flowing. During swabbing, 300 – 400 bbl of water, heavily laden with partially broken polymer, was recovered before the well kicked off flowing natural gas. The well flowed essentially dry gas for seven months, with production rate declining slowing from 400 – 500 Mcfd to 100 Mcfd. Eight months after treatment, the rate dropped to 60 – 80 Mcfd, and the well started to produce one bpd of "slick" water (this indicates that polymer is still being removed even eight months after the job was performed). The well produced over 14 MMcf of gas the first month. Payout occurred within three weeks. Through March 2001, Micro-Bac has performed a handful of similar treatments worldwide, with all but one (and that one had operational problems) considered successful. Oil well, West Africa. Although it had not stopped completely, oil production (Fig. 2) in this West African producer was erratic and declining. Residual damage from accumulated polymer fluids was suspected. The treatment program was designed based upon well characteristics and production goals. Biological stimulation products were selected to metabolically degrade residual high-molecular-weight compounds that were causing damage and reducing flow.

An injection program was designed to squeeze biological stimulation fluid into the formation to remove damage and increase produced fluid flow. Biological stimulation products were mixed on site with strained sea water. The treatment solution was approximately 650 bbl, at a dose concentration of 20,000 ppm active biological stimulation agent. Injection was performed through the production tubing, and injection rate was maintained below fracture pressure. After injection, the well was shut in for five days to give the biological stimulation fluid time to degrade the residual compounds. In the reservoir, the microbes migrate to the damage, and can invade channels that may have been blocked and, thus, bypassed during injection. Because the biological stimulation products are all-natural and non-hazardous, no special precautions were needed to handle produced fluids when the well was returned to production. When opened to production, rates increased 44%, as the well unloaded accumulated viscous material described as "garbage." Fluids produced from the well were analyzed and found to contain heterogeneous amounts of viscous material for up to two weeks after production resumed. In the first month following treatment, the well produced an incremental 7,000 bbl of oil. Some nine months after treatment, production is still near 600 bopd, which represents an increase of more than 40% over pre-treatment rates. Payout occurred within less than one month. Worldwide, several hundred analogous treatments have been performed with a success rate of about 90%. Conclusions. As with most technologies, the key to successful biological stimulation treatments lies in identifying that polymer damage is responsible for the reduced productivity. Knowing that, treatments can be sized properly, and treating procedures developed. These example treatments in a southwest Texas gas well and a West African oil producer illustrate how effectively the treatments can work. Treatments were relatively low-cost, straightforward and low risk. Economic results were quite attractive with payout occurring in one month or less. PTD

|

||||||||||||||||||||