Hydrochloric/phosphonic acid combination improves well performance

Hydrochloric/phosphonic acid combination improves well performanceRichard Russell, St. James Oil Corp., Los

Angeles, California, and

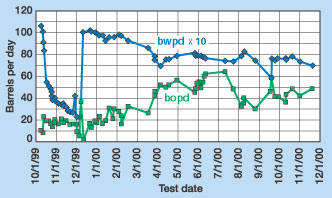

Walt North,* RMC Consultants, Inc., Tulsa, Oklahoma Bottom line. St. James Oil Corp. used a combination hydrochloric / phosphonic acid stimulation treatment in four wells in the Los Angeles Downtown oil field to improve well performance and inhibit calcium carbonate scaling. In the four treated wells, combined production response has averaged about 122 bopd, a 220% increase over production prior to acid treatment, and slightly higher than would be expected with conventional hydrochloric acid treatments. Post-treatment decline rates (3 to 16 months after treatment, depending on the date the well was treated) also have been measurably flatter than would be expected following conventional treatments. New approach for controlling scaling. Oil production from the 250-acre Los Angeles Downtown oil field is from the Upper Miocene Puente formation, a turbidite sandstone. The Broadway zone of the Puente is composed of thinly interbedded sands and shales at 2,900 – 3,500 ft. Wells producing from the Broadway zone have strong tendencies to produce calcium carbonate scale, and many are treated for scale control. For clean-out, best results have been obtained using minimum volumes of low-strength hydrochloric acid. However, decline rates after stimulation typically have been relatively high; and generally, within six months to a year, production rates return to pre-stimulation rates. To obtain longer-lasting treatment effectiveness, St. James employed phosphonic acid in conjunction with a conventional hydrochloric acid treatment. Many scale treatment programs, such as scale inhibition squeeze treatments, have demonstrated the effectiveness of phosphonic acid in the treatment of calcium carbonate scale. The addition of phosphonic acid to the treatment program primarily was designed to provide longer-term inhibition to the formation of calcium carbonate scale, following scale cleanup by the hydrochloric acid. In addition, the phosphonic acid reacts with the aluminum in the clays and other feldspars to form a temporary protective film, enhancing treatment penetration and reaction effectiveness from the hydrochloric acid, which reacts with and eliminates migrating fine particles that interfere with oil movement into the wellbore. St. James selected four representative wells, each exhibiting characteristically high scaling tendencies and substantial decline over the last few years, to demonstrate the effectiveness of the hydrochloric / phosphonic acid system. Well treating procedure. The two-stage acid treatment procedure was similar for each of the first three wells treated – a 10% hydrochloric acid wash treatment in the first stage, followed by a second stage of lease water containing phosphonic acid and other protective additives. The treatment for the fourth well was modified to a combined hydrochloric / phosphonic single-stage treatment to further enhance the penetration and effectiveness of the hydrochloric acid. In preparation for the acid treatment, the pump and tubing were pulled and a casing scraper was run to locate any casing restrictions, clean the casing walls and locate the top of fill. Any fill above the zone to be treated was cleaned out. Before treating, all chemicals were tested for compatibility with lease fluids. In the first stage, the interval was treated with 15 gal/ft of 10% hydrochloric acid, circulating and washing from the bottom up at a 2-bpm rate with maximum allowable pressure of 2,000 psi. In the second stage, the interval was washed with 15 gal/ft of phosphonic acid solution (roughly 15 gal of phosphonic acid per 1,000 gal of filtered lease water). Typical acid treatment additives, which included corrosion inhibitor, non-emulsifier / wetting agent, iron control agent and anti-sludge agent, also were used. Each well was returned to production about one week after stimulation. Treatment results. The first well selected for acid stimulation was the Venice Community No. 6 (Well VC6). Reworking of the well was conducted and a pre-treatment well test was performed, indicating 10 bopd and 1,060 bwpd. This high water cut is normal for this field when a well is returned to production after a brief shut-in period. Well VC6 was stimulated with the acid treatment on October 3, 1999. A well test three weeks after treatment indicated an oil rate of 17 bopd and 1,023 bwpd. Total fluid production then dropped significantly, and two months after treatment, fluid level tests indicated that the submersible pump was not operating properly. The pump was pulled and repaired on December 1, 1999, and the well placed back on production. The well began cleaning up (producing sludge) at that time, and the fluid level was being reduced. Well VC6 production went up gradually from an average of about 10 bopd prior to treatment. Following the pump repair, production rose from 17 bopd to a peak of 63 bopd eight months after the stimulation treatment, then settled to approximately 42 bopd, Fig. 1. Well VC6 currently produces 48 bopd with no observable oil production decline.

Similar treatment procedures were conducted on the remaining three wells, Venice Community No. 2 (VC2), L. A. Unit No. 8 (LAU 8) and Venice Community No. 3 (VC3), see Table 1. Some modifications were made to the treatment additives because of sludge forming in VC6 following treatment. No treatment or production problems have been encountered to date in any of the other three wells. Water production in these high water-cut wells has remained around 90 – 95% following treatment, about the same as pre-treatment rates.

As might be expected, treatment response varied considerably between wells. However, except for pump and sludge production problems in Well VC6, all four wells responded favorably to stimulation treatment and, thus far, have exhibited low-to-flat production decline characteristics. Well VC6 has the longest post-treatment production history (16 months). Prior acid stimulation projects in the field have experienced high decline rates following stimulation, and typically, in less than one year, production rates return to pre-stimulation rates. The decline rate of Well VC6’s production has remained relatively flat. This is very encouraging, and a good indication of lower decline rates to be expected for the other three wells, which have less production history. Combined, the production increase following initial treatment response was 160 bopd, settling to 122 bopd, a 220 % increase over pre-treatment rates, Table 1. Production increases of this magnitude are at least as high as are typically experienced with conventional hydrochloric acid treatments, and early indications are that post-treatment decline rates are significantly lower. Incremental treatment costs per well, including chemicals and well work, for the combined hydrochloric / phosphonic acid treatments are only about 16% higher than for conventional hydrochloric acid treatments. Payout for the combined hydrochloric / phosphonic acid treatments was less than four months. Certainly, the production response to the combined acid treatments has produced economic benefits that justify the extra costs. Conclusions. The combination hydrochloric / phosphonic acid treatment worked well in this turbidite sand reservoir. For the treated wells, initial response was higher and post-treatment decline rates shallower than experienced with conventional hydrochloric acid treatments. Although individual well results were quite variable, the results indicate that the Broadway zone can be successfully stimulated with the new acid system. Although it is too early to determine the long-range effects on sustaining lower decline rates, the initial results are very encouraging. PTD Acknowledgment This work was performed in a cost-shared project with the U.S. Department of Energy through the "Technology Development with Independents" program administered through the National Petroleum Technology Office in Tulsa, Okla. For more information, visit the www.npto.doe.gov website.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||