Pumping large water volumes revives "watered-out" gas zone

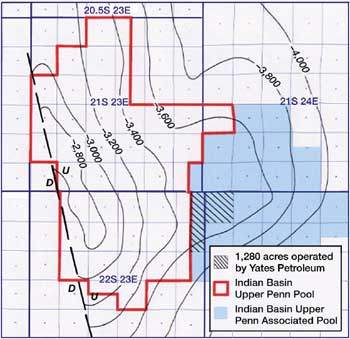

Pumping large water volumes revives "watered-out" gas zoneBrian Collins, Dave Boneau and Pinson McWhorter, Yates Petroleum Corp., Artesia, New Mexico Bottom line. Operators in the huge Indian Basin field have found that significant volumes of gas can be produced far behind the encroaching water front by pumping large volumes of water along with the gas. Yates Petroleum, one of the early users of this "secondary-gas" technology, is producing about 38 MMcfd from a two-section area where the carbonate reservoir lies 200 ft below the current water-gas contact. Field history. Indian Basin field in Eddy County, New Mexico, was discovered in 1961 and has produced 1.7 Tcf from a huge carbonate mound with an active water leg. The carbonate interval is about 300 ft thick on a structure where the original gas-water contact sat 1,000 ft below the crest. There are 17 wells high on the structure that have produced 40 Bcf or more. The best well has produced 51 Bcf. Over the years, the original operators simply shut in and abandoned wells as the water moved up the structure. A total of 26 out of the original 56 wells have been abandoned as the water has moved at least 700 ft up the structure during the past 30-plus years. Indian Basin has a relatively weak water drive – original reservoir pressure of 3,000 psi has declined to below 1,000 psi in the gas cap. In 1993, Yates Petroleum Corp. decided to explore near the base of the structure in hopes of finding a relatively small oil leg beneath the huge gas cap. Yates produced some oil and water from its first wells, but the oil production was disappointing. Then, Yates moved updip and re-entered a well that had produced 28.3 Bcf of gas before it was abandoned in 1986. Over the past few years, Yates discovered that gas production increased as more and more water was pumped out of the carbonate formation. The best Yates well produced 2 bopd, 9,460 MMcfd and 3,650 bwpd in December of 1999. Indian Basin produces from Canyon (Upper Penn) dolomite at depths of 7,000 to 8,000 ft. The original pool has been prorated since production began in 1965, with an allowable in recent years of about 6.5 MMcfd per 640-acre spacing unit. When Yates began drilling for hydrocarbon and water behind the water front, Yates and other operators sought approval of a new Indian Basin Associated pool with 320-acre spacing and a higher allowable to compensate for the extra costs of water handling. The allowable in the Associated portion of the Indian Basin field is about 9.7 MMcfd per 320-acre spacing unit, or approximately 19.5 MMcfd per section. The Yates project. Fig. 1 shows the structural contours on top of the Upper Pennsylvanian carbonate and locates both the original Upper Penn pool and newer Associated pool. The 1,280 acres redeveloped by Yates and its partners is located in E/2 of Section 1-22S-23E, E/2 of Section 12-22S-23E and all of Section 6-22S-24E.

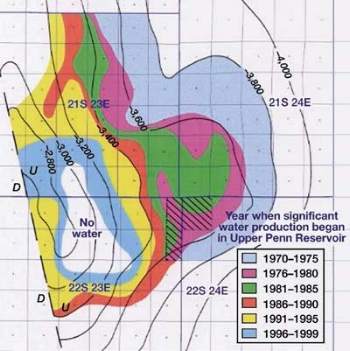

The contour map on page 1 roughly shows how water has encroached over the years at Indian Basin. Wells at the base of the structure began to water out in the early 1970s. Note from the map that the water has not moved uniformly up the structure. The eight wells that still produce no water actually lie 200 ft or so below the crest of the structure.

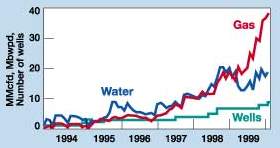

The only original well in the 1,280-acre Yates project is located in the NW/4 NW/4 of Section 6. It was drilled in 1965 by Amoco and completed in the top 100 ft of the dolomite. The well was abandoned in 1986 after producing 195,000 bbl of oil and 28.3 Bcf. In 1993, Yates re-entered the plugged wellbore and initially attempted to produce oil from deeper in the dolomite section. When this effort proved discouraging, Yates went back to the old Amoco perforations and completed the well in early 1994, with initial potential of 10 bopd, 1,740 Mcfd and 4,633 bwpd via electrical submersible pump. Yates was fortunate to have an extensive gas and water gathering system operating in the Dagger Draw field about six miles north of the Indian Basin project. This system was extended south into Indian Basin in anticipation of the Upper Penn redevelopment. Fig. 3 shows both gas and water rates, along with the number of active wells for the Yates project.

Progress was slow at the start. Yates added two additional wells at the start of 1995, and production gradually increased to about 4 MMcfd and 5,000 bwpd during 1996. Yates installed bigger lift equipment at the start of 1997 and added a fourth well at midyear. These actions set the project on the way to success; and production grew to 10 MMcfd by the end of 1997. With the project starting to work, Yates drilled additional wells until there were nine producers – five in Section 6, two in E/2 of Section 1 and two in E/2 of Section 12. Notice that the relative gas rate remained below 1.0 Mcf/bbl water until about April 1999. In the past year, the water rates have leveled off and the gas rates have increased until each 320-acre spacing unit is producing its gas allowable. Summation. Production from the 1,280-acre project to the end of 1999 has been 300,000 bbl of oil and 20 Bcf plus 20 million bbl of water. Each well costs about $900,000 to drill, complete and equip. These costs include $120,000 for a submersible pump and $50,000 for surface facilities. The significant monthly operating costs are $7,500 for electricity and $0.17/barrel of water disposal costs. The project paid out in 1999 and is generating additional income. The main lesson here is that carbonates are very heterogeneous and very complicated. Yates tried the same approach without success in the same formation at the McMillan Upper Penn pool further north in Eddy County. At McMillan, the structure is much smaller (25 Bcf) and the water drive is stronger. At McMillan, the water appeared to move uniformly up the structure. At Indian Basin, positive factors may be the dolomite reservoir, the partial water drive and the erratic water movement over the history of the field. Partners in the Yates project include Kerr-McGee and Santa Fe Snyder. Both Kerr-McGee and Santa Fe Snyder, along with Marathon, have installed submersible pumps at some of their own wells within the water leg at Indian Basin. It took four or five years for this project to prove itself; but now what started as a bold experiment promises to add substantial reserves for many operators at Indian Basin. The authorsBrian Collins is operations manager for Yates Petroleum Corp. He is a graduate of New Mexico State and worked as a completion engineer for Exxon before joining Yates in 1989. Dave Boneau is engineering manager for Yates Petroleum Corp. He is a physics graduate of Notre Dame and Iowa State Universities and worked at Phillips Petroleum before joining Yates in 1980. Mr. Boneau chairs both PTTC’s Southwest region and the New Mexico Oil and Gas Engineering Committee. Pinson McWhorter is supervisor of reservoir engineering at Yates Petroleum Corp. He is a petroleum engineering graduate of the University of Texas at Austin and worked for Tenneco in San Antonio before joining Yates in 1990. |

|||||||||||||||