Upstream companies enhance production at existing operations through the use of simulation models.

Sanjeev Mullick, Aspen Technology, Inc.

Simulation models have been extensively used in the downstream refining and chemical industry since the 1980s, lowering engineering and operating costs, maximizing throughput, improving reliability and increasing margins. Thus far, this technology has not been leveraged extensively enough in the upstream industry. However, leading upstream companies are successfully deploying simulation models and in the process “finding” new reserves and production.

INTRODUCTION

Traditionally, E&P firms have focused on achieving growth through discovering and developing new reserves to increase their production rate. Today, there is greater emphasis on economically maximizing production from existing assets.

Achieving production growth through subsurface modeling and by enhanced recovery techniques are some ways to do it. However, there are other processes that impact production and reserve growth: the proper engineering and efficient operations of the surface facilities. Oftentimes, surface facilities are constraints on production. A proven way to understand and relieve these constraints is through the modeling of these facilities.

With leading owner-operators and E&P companies leveraging real-time data to improve operations, an examination of innovative work practices and technologies used in the upstream industry shows how integrated engineering environments support best practices to attain new levels of enhanced operation.

TRENDS IN INTEGRATED ENGINEERING

Workflow consistency, from conceptual engineering through operations, lowers the effort required to design, build and operate facilities. Leveraging the models used to design a facility and applying them in operations further enables engineering knowledge to be shared throughout the lifecycle of the asset.

These benefits of lifecycle modeling, such as higher productivity, lower costs, reuse of models and data, are being delivered by today’s integrated engineering environments and their workflows. Integrated engineering enables multiple applications to easily work together, thereby delivering greater benefits, Fig. 1.

|

|

Fig. 1. Integrated process engineering workflow diagram.

|

|

CHARACTERISTICS OF UPSTREAM ENGINEERING ENVIRONMENTS

Today’s leading upstream engineering environments and workflows have the following characteristics.

Subsurface and surface engineering are coming together. While there remain significant differences between these disciplines, including the fact that they operate in different time-scales (years vs. hours or even minutes), innovative solutions are enabling appropriate asset-wide integration from the reservoir to the wells, to gathering networks and surface facilities. These integrated asset models are now being successfully deployed for intelligent field operations, supported by greater amounts of available data.

Real-time data utilization. Large volumes of real-time data from production are represented visually so operators can quickly make fact-based decisions to optimize performance, but this is not enough. As with refineries and chemical plants, the complexity of the large volume of data is too great for an operator to process quickly. Using the process models that were the source of the design parameters for the plant in conjunction with the real-time data gives the operator actionable information on performance and best operating practices.

These evolving business trends around integrated engineering and workflows are supported by greater utilization of process simulation, model deployment and IT infrastructure. The focus is now shifting to model deployment in real time and the IT infrastructure that enables it.

Models to support and optimize operational performance. Once an asset is built and operational, owner-operators are increasingly utilizing models to support and optimize performance. Examples of applications include steady-state and dynamic models to guide operating decisions; performance and equipment monitoring; offline and real-time optimization; and improving planning models for asset lifecycle.

Common information management systems and easy availability of plant data. In the last decade, IT infrastructure has evolved rapidly. Today, in many organizations, operational data is commonly available on every desktop across all disciplines and locations. This fosters common understanding of operations; facilitates collaboration between disciplines; enables remote monitoring and performance improvement based on best practices, and by leveraging the expertise across the organization.

MODELS AND REAL-TIME DATA ENHANCE OPERATION

Over the last several years a number of successes have been reported on the use of models, both steady-state and dynamic, in engineering and model-based decision support for operations. Selected examples are discussed below.

Asset-wide production optimization. BP uses asset-wide models for daily optimization to predict the operating conditions and available safety margins of the entire asset from wellheads to tankers. Such asset-wide models utilize process simulation integrated with in-house and commercially available software tools.

The system displays the best selection of well production schedules and process facility parameters to the operations staff, thereby maximizing profit, while respecting actual asset constraints and the economic inputs to the model. Cross-disciplinary knowledge is shared during the construction and deployment of the asset model, leading to a better understanding of the interaction between the petroleum wells and the facilities on the platform.

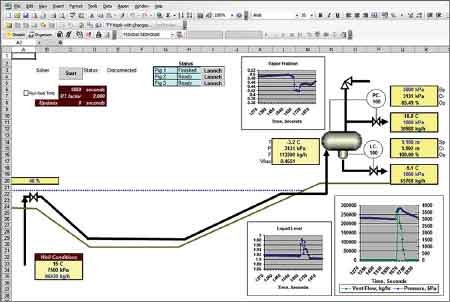

This model-centric approach has been utilized in the business lifecycle of the BP Harding Daily Optimizer. The BP North Sea Harding asset (Fig. 2) consists of three types of fluid contained in 15 wells, producing heavy, high-viscosity crude oil. The Daily Optimizer, using the simulation model, receives information from the data historians, reconciles data for the rigorous asset-wide simulation model, and generates optimized recommendations for operators via a convenient Excel based interface. The system reported benefits of an additional average gross oil production of 4,300 bpd, with very low incremental production costs.1

|

|

Fig. 2. BP’s Harding asset.

|

|

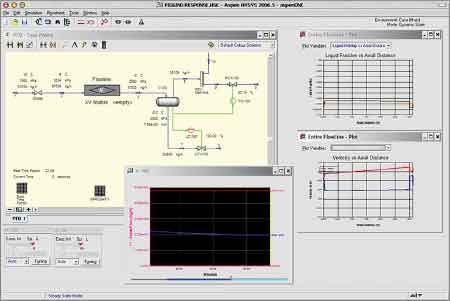

Accelerated commissioning with integrated engineering and controls analysis. Genesis, an engineering and consulting firm serving the E&P industry, recently reported a creative application of dynamic modeling to accelerate the commissioning of a compression train for an offshore FPSO in the North Sea.2 The FPSO was being redeployed to a new field with different production composition and GOR. This required installing new compressors for which the FPSO was brought into drydock to retrofit the new equipment and its controls. The client wished to accelerate the project while simultaneously mitigating project risk.

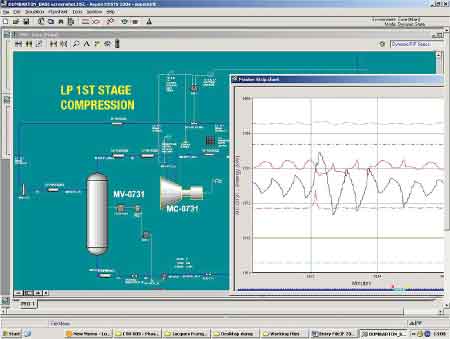

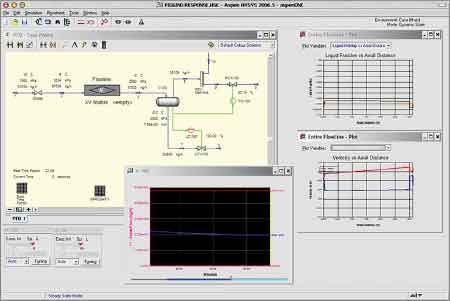

Genesis evaluated the situation and developed Aspen HYSYS Dynamic simulation models (Fig. 3) and connected them to the actual control systems through data and communication gateways. This solution replicated real-world conditions and variables enabling rigorous testing and pre-commissioning of the compressors and their controls while still in drydock. This onshore effort uncovered critical errors and other problems in the control system and its logic-all of which were easy and far less expensive to remedy while still in drydock. This removed a major project uncertainty and risk. The integration of the control system was no longer on the project’s critical path, and all issues were resolved independently for an early and seamless deployment. The net result was an offshore startup that was safe, two weeks ahead of schedule, with no additional expenditure for specialists to travel offshore for expensive troubleshooting and correction, and faster time to first oil. The reported savings was more than $3 million. Since then, the customer has installed a replica of this system at their onshore training facility, which allows them to train operators and help with trouble-shooting.

|

|

Fig. 3. Compressor dynamic model by Genesis for FPSO revamp.

|

|

Accelerated commissioning of an MEG system. Another interesting example of the use of dynamic simulation for verifying design and process control system prior to commissioning is the MonoEthylene Glycol (MEG) regeneration system for StatoilHydro’s Asgard B platform.3,4 This platform processes oil and gas from Midgard Field in the North Sea. MEG is injected at the wellheads for hydrate suppression in the subsea pipeline carrying gas and condensate. On the platform, the MEG is recovered, regenerated and reused. The MEG reclamation begins with a conventional process of inlet separation, heating and liquid separation, additional heating and degassing. This is followed by a novel two-step process: vacuum-flash separation for water removal, and crystallization for particulate and ion decontamination. The final distillation stage removes the remaining water resulting in a lean MEG product suitable for reinjection, Fig. 4.

|

|

Fig. 4. Monoethylene glycol regeneration process on Asgard B platform.

|

|

This system is one of the largest operating MEG recovery and regeneration units on an offshore platform. The simulation model was successfully used to test overall control strategies and startup procedures prior to commissioning. It was also used to train operations staff on how the new unit would work. As a result, the new unit was commissioned and brought online faster, with reduced commissioning costs, and reduced daily utility operating costs.

Once the unit was commissioned, an excellent match between plant data and model predictions was observed. This led to the model being used to train operations personnel and to share knowledge between disciplines to foster a better understanding of the interactions between the control system tuning parameters and the process.

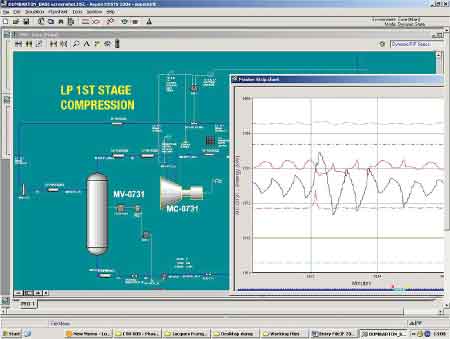

Gas production allocation and pipeline monitoring. A customer of Xodus, an engineering and consulting firm focused on E&P, was experiencing difficulty in monitoring the operation of two FPSOs that were linked by pipeline to a gas production platform. Further complicating this situation was the fact that the FPSOs could operate in mixed mode (import or export), had limited chromatographic data between them to properly allocate production, and there existed the potential for two-phase flow. This could trigger a potential process trip.

The customer sought a model-driven, web-based system for easy onshore and platform use for monitoring and critical decision-making support. Xodus developed such a system using dynamic simulation with real-time data links, and a web-based thin client application.5

The operator of this North Sea gas asset is now able to view model-generated data for insight into process and pipeline performance in real time (Fig. 5) perform accurate production allocation, and develop predictive data for future operating states.

|

|

Fig. 5. Platform phase envelope diagram.

|

|

Deploying models for occasional users. The types of successes described thus far have, over the years, established the value of simulation models in the E&P industry. This success has led to companies and users asking for tools to further ease the deployment of models quickly to occasional users who may not be familiar with the simulator environments. Aspen Simulation Workbook (ASW) addresses this need, enabling the company’s simulators to link with MS Excel. ASW does not require the user to know programming languages like Visual Basic, providing out-of-the-box integration with Excel with a convenient point-and-click, copy-and-paste mechanism for linking variables and graphics in an Excel spreadsheet with the underlying model. Model developers can now quickly put Excel-based interfaces on top of their detailed, rigorous models and deploy them in the field to non-expert users.

One such example application is for simulating pigging operations using the model and its hydraulics module, Fig. 6. This model aids in understanding the system’s response to a pig moving through the pipeline and its impact at the receiving end with respect to liquid levels, vapor fractions, pressure, vent flow, etc.

|

|

Fig. 6. Pigging simulation application.

|

|

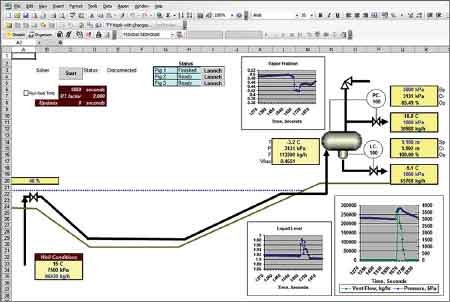

For end users this operations decision support tool is presented with an Excel front-end (Fig. 7) using ASW. The user simply uses a pointing device to click on the “launch” and “start” buttons on the screen to initiate the simulation of the dynamic response of the system to the pig traveling through the pipeline.

|

|

Fig. 7. ASW interface for pigging simulation application.

|

|

As shown in Fig. 7, the results are presented on dynamic trend displays and data fields. This helps operators understand how the setpoints of separator pressure and separator level impact the capability of the system to handle slugs generated by the pigging operation.

CONCLUSION

In the quest for new reserves and production, E&P companies are looking to optimize recovery from their existing assets. Running hydrocarbon processes at low cost, reliably and safely are the same business objectives refining and chemical firms have been achieving with model-supported decision making. This is helping E&P companies extract even greater value from their capital investments and subsurface assets. They can operate at higher levels of efficiency and agility, with greater transparency and accuracy in decision making.

The value creating modeling applications discussed above and their integration with other business functions point to the importance of the following three principles at the foundation of an integrated engineering and operations tool-set.

Model-centricity. Models used throughout the lifecycle from engineering to operations and business decision making need to be consistent with each other. Consistency is much more important than full reuse of the models. Consistency in the underlying models drives consistency in decision making across the enterprise in engineering, operations and business.

Data-centricity. Data entered once in the lifecycle must be reused throughout the lifecycle and across the organization. Data-centricity drives efficiency, accuracy and collaboration across the organization. Capturing real-time data and using it in models is a logical next step.

Concurrent engineering. The ability to simultaneously model, analyze and design results in rapid screening of the available options and identification of optimum designs early in the lifecycle, resulting in better project ROI.

In addition, the integrated toolset must also provide an open environment for in-house and third-party tools to be easily integrated. This is especially true as the worlds of subsurface well models and the surface production facilities come together.

Managing the lifecycle of assets in the future is not merely survival of the fittest and the fastest-but the ability to adapt and respond to business and engineering challenges and opportunities with agility is also becoming critical. Better-informed decision making is required to achieve optimum production in the face of rising costs, and in maintaining safe and environmentally sensitive operations at ever more remote and complex assets. Significant benefits can be achieved by transforming asset data into knowledge, from the control room to the boardroom, and to concurrently drive consistent decision making in engineering, operations and business.

LITERATURE CITED

1 Stenhouse, B., “The BP Harding daily optimizer,” Hyprotech 2000, Amsterdam, November 2000.

2 Robertson, I. and T. Baxter, “Accelerated dynamic compression train commissioning using HYSYS dynamics,” AspenTech User Group Meeting, Frankfurt, April 2007.

3 Billington, P. and D. Kroger, “Verification of the process control system for the Asgard B Mono-Ethylene-Glycol (MEG) regeneration module using HYSYS plant dynamic simulation software,” Hyprotech 2000, Amsterdam, The Netherlands, November 2000.

4 Howell, A., Hanson, K., Dhole, V. and W. Sim, “Engineering to business: Optimizing asset utilization through process engineering,” CEP, September 2002.

5 Jones, A., “The XPLORE pipeline monitoring and allocation system,” AspenTech User Group Meeting, Frankfurt, April 2007.

|

THE AUTHOR

|

|

|

Sanjeev Mullick is the director of product marketing for AspenTech’s Process Engineering business. He has over 20 years of experience in engineering, process automation, business consulting and marketing in the oil and gas, refining and petrochemicals industries. His background includes successfully delivering solutions in simulation, model deployment and real-time optimization. Mr. Mullick was previously with SimSci and the Pyrotec division of Technip. He has an MS in chemical engineering from the University of Michigan, Ann Arbor.

|

|

|