Nondamaging, self-diverting acid stimulations revive Egyptian oil fields

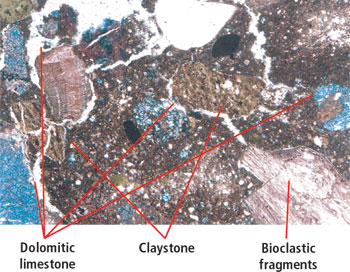

Production OptimizationNondamaging, self-diverting acid stimulations revive Egyptian oil fieldsA matrix stimulation solution developed for heterogeneous carbonate reservoirs was used to treat temporarily abandoned, heavy oil producers in Egypt's eastern desert, resulting in an unprecedented, four- to eight-fold increase in output from mature fieldsMathew Samuel and Depinder Sandhu, Schlumberger A new matrix stimulation solution has been developed for heterogeneous carbonate reservoirs that historically have presented challenges when stimulating with conventional methods. The tailor-made stimulation design uses an intensified, viscoelastic diverting acid (VDA) system in combination with a mud and silt remover (MSR). The intensified VDA system stimulates low-temperature dolomites and automatically diverts fresh acid into the unstimulated, low permeability sections. The system provides not only good dispersion of drilling-induced damage, but also helps in the suspension of formation silts out of the wellbore. Treating mostly temporarily abandoned, heavy oil producers with the VDA-MSR system created an unprecedented, four- to eight-fold increase in production from a cross-section of mature fields in Egypt's eastern desert area. STIMULATION CHALLENGE The main producing formations in Egypt's eastern desert fields are low-temperature, dolomitic carbonate reservoirs consisting of multiple layers with wide permeability ranges. While these layered, fractured formations typically must be stimulated for optimum production performance, their characteristics historically have hindered effective stimulation. Previous stimulation efforts have focused mainly on various conventional matrix stimulation treatments, with largely lackluster results. Hydrochloric acid (HCl)-based stimulation systems exhibit low reaction rates with dolomitic rock compositions, particularly at low temperatures. Achieving uniform zonal coverage during stimulation treatments, using conventional matrix fluidsand methods in carbonates, can also be difficult, given the heterogeneityand extremely high permeability contrasts among the formation layers.In this area, conventional chemical diversion techniques had been applied in the past. However, results were not encouraging because of damage associated with the use of polymeric systems. Recent stimulation treatments using a nondamaging, surfactant-based system have been found to be successful in achieving total zonal coverage and uniform stimulation in these low-temperature dolomitic formations with inherent permeability contrasts. CONVENTIONAL STIMULATION FLUIDS Generally,stimulation fluid diversion is recommended in carbonate reservoirs with payzones that exhibit different injectivities stemming from their varying permeabilities and severity of formation damage. Without diversion the acid seeks the path of least resistance and enters only a small portion of the interval being treated. During diversion, chemical diverting agents temporarily block these intervals, forcing the subsequent acid stages into the more damaged and/or less-permeable payzones. Conventional stimulation/diversion treatments use regular or retarded acids in conjunction with chemical diverters (including foams) to fully stimulate long, non uniformintervals. Historically, most conventional chemical diverters were polymer-based and had limited success. Polymers inherently have solids that often induce damage by leaving behind residue in the formation. Polymer-based fluids require a breaker and metal cross-linkers, such as iron or molybdenum. These additives, in turn, require close pH levels to activate presenting a narrow working window in which to achieve diversion. In addition, tubing iron can induce the polymer to cross-link prematurely, which can increase friction – and thus horsepower requirements – for pumping the treatments. NEW STIMULATION FLUID, METHOD A new VDA system that is free of damaging polymers and solids has been proven successful in diverting and stimulating large heterogeneous carbonate reservoirs. The non-polymeric fluid system is similar to the field-proven, ClearFRAC* technology, a clean and nondamaging viscoelastic surfactant used in proppant fracturing. Since VDA contains no polymers, the fluid system does not require metallic cross-linkers such as iron or zirconium, eliminating any potential damage from precipitation of metal hydroxides and sulfides. This system feature makes it the preferred fluid in sour wells. In addition, compared to other diversion systems, the surfactant system displays lower friction pressure during a job, meaning less horsepower is required. Less friction allows higher pumping rates and greater treatment effectiveness. Diversion pads and reactive fluids are required with conventional methods to uniformly treat large intervals and effectively stimulate individual payzones. However, the surfactant-based VDA system stimulates and then diverts automatically via in-situ viscosification, thus eliminating the need for other diverting materials like foams or particulates.The self-diverting nature makes the fluid system well-suited to creating large, layered intervals with high permeability contrasts. Its use has been found to significantly improve treatment effectiveness in historically challenging carbonate acid stimulation jobs performed around the world. TAILOR-MADE STIMULATION SOLUTION While VDA was identified as the preferred stimulation solution for mature dolomitic fields in Egypt's eastern desert, the fluid system had to be tailored according to specific formation properties and reservoir conditions. In-depth petrographic studies were undertaken to analyze the formation mineralogy for candidate wells. As shown in the photomicrograph, a typical rock sample contains differing types of rock fragments and bioclast debris, Fig. 1. Dolomitic (ferroan) limestone is the main component, with lesser quantities of claystone, glauconitic and carbonate cemented sandstone. Bioclast fragments are predominantly bivalve shell debris and minor forams. Rock and bioclast fragments are held together by detrital clay (dark brown) matrix. The mineralogy knowledge gained was used in the lab to tailor the stimulation fluid for each well treatment.

A series of lab tests were conducted at the Schlumberger Client Support Lab utilizing the company's PowerSTIM* team expertise to developa stimulation fluid system that best suited this area's dolomitic reservoirs, given their low temperatures. To address the target formation's stimulation requirements, a specially engineered MSR stimulation fluid, which had been used previously in other successful field applications, was applied in conjunction with VDA. The VDA-MSR system was tested on formation samples using various additives in differing amounts under simulated bottomhole conditions to identify the optimal additive composition. Technical teams proved conclusively the specific percentages required to achieve the fluid system's desired properties, thereby providing the optimum rate of chemical dissolution while ensuring that nodamaging precipitates were created. Final lab demonstrations of the optimized systems were reviewed prior to their use in the candidates identified for well treatments,which were heavy oil producers, most of which had been temporarily abandoned for an extended time. These field applications utilizing the innovative stimulation system would mark the first use of intensified VDA technology. VDA STIMULATION TREATMENTS VDA systems are formulated with as much as 28% HCl mixed intoa zwitterionic, viscoelastic, surfactant base fluid. The normal additives required in acid treatments, like inhibitors, chelants or iron control agents, are compatible with VDA. Depending on the amount of acid present, the prepared VDA system's initial apparent viscosity (at bottomhole static temperature BHST) is about 2–3 cp. The viscosity remains low while pumping through the tubing and does not increase until it reacts with the carbonate formation. The surfactant and additives were mixed into HCl for the well stimulations. Treatment intervals for the candidate wells ranged from 30–40 ft.A summary of formation properties is provided in Table 1. Throughout a typical treatment interval, the permeability ranged from 20–100 md. Candidate wells initially treated with this technique had a low BHST of 110–130°F. However, the VDA system can be applied in reservoirs with temperatures as high as 300°F.

VDA can be pumped as a single fluid to stimulate and divert in one step. It also can be pumped in several stages, alternating with regularor retarded acid stages. The fluid's simplicity, coupled with the flexibility in treatment design, make execution easier and less cumbersome. Fewer holding tanks and surface equipment are needed and, therefore, less space is required for stimulation operations. In these treatments, the MSR and intensified VDA fluids were batch-mixed and administered in alternating stages. A typical stimulation jobs chedule is outlined in Table 2. One of the light oil producers was a dual completion, with the upper zone a sandstone and the lower zone the low-temperature dolomite. A dual injection technique was used to administer the VDA-MSR treatments in this well.

The other wells were heavy-oil, open-hole producers. In these applications, stimulation treatments were pumped through the Jet Blaster tool deployed on 1.5-in. coiled tubing. Since this surfactant-based fluid viscosifies in the formation rather than in the tubing string, it can be pumped easily through coiled tubing in both open- and cased-hole completions. Unlike polymers, VDA fluids do not contain solids that can bridge when pumped through coiled tubing. In fact, in light of their lower friction pressures exhibited during pumping, VDA fluid systems provide the best results when used with coiled tubing for self-diverting and stimulating carbonate reservoirs. VDA MECHANISM OVERVIEW The surfactant-based acid formulation stimulates the highest permeability zones first, in a manner similar to conventional and retarded acids. After the VDA system enters a high permeability layer, it reacts with the carbonate rock matrix and creates wormholes through the formation. The reaction between the HCl and rock's calcium carbonate (CaCO3) produces calciumchloride (CaCl2) brine (spent acid). The presence of CaCl2, and a pH increase resulting from acidspending, are needed for the acid's in situ viscosification and gellation. When sufficient CaCl2 brine is generated, it reacts with the surfactant present in the diverting acid and forms long, worm-like or rod-like micelles, which entangle/aggregate to impart a higher viscosity to the fluid system. This viscous system temporarily plugs the wormholes and fissures, as well as existing high-permeability streaks and channels. Thus, the remaining VDA fluid system and/or subsequent acid stages are forced to divert into the untreated, less-permeable layers. While other diverting fluids can break as the pH approaches 3 to 4, the VDA viscosity remains stable at a pH above 2. This maintains viscosity control and eliminates the possibility of premature viscosity breakdown between job stages – or in the event of equipment failure or job delays. During flowback after job completion, either hydrocarbons or producedwater effectively break the surfactant microstructure and lower the viscosity down to that of water. Post-flush with solutions having diesel or mutual solvents will also enhance the VDA treatment fluid's breakdown and flowback. VDA-MSR TREATMENT RESULTS To date, the optimized system has been used for more than 20 treatments in this area's low-temperature dolomitic formations. Following the well treatments, field production has increased four- to eight-fold, significantly beyond expectations. The pressure responses that occurred during treatments indicated that marked diversions took place. This is illustrated by a well plot for a typical VDA-MSR treatment, Fig. 2. The wells cleaned up quickly after treatment. Most VDA-MSR – treated wells showed only a gradual production decline, compared to conventionally stimulated wells in which the production decline was far more rapid.

Moreover, high oil-producing rates of the treated wells paidback stimulation costs within a period ranging from one day to just over one month, with most treatments paying out in less than one week. This encouraging level of increased output has influenced the drilling and development plans for many fields, a fact substantiated by a marked increase in the area's drilling activity. Further, to duplicate these benefits of substantial production increases and quick payouts, the same stimulation fluids will be utilized for most future candidate wells. The recent, successful implementation of intensified VDA technology in Egypt has elevated it to one of the preferred matrix stimulation methods. An increasing number of operators are now willing to consider this specially engineered stimulation system as an effective tool to boost production and generate attractive return on investment. This system has shown that technological innovations can provide cost-effective solutions to past stimulation problems, and continue tochange the way operators approach stimulation challenges in Egypt and throughout the Middle East.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- What's new in production (February 2024)

- U.S. operators reduce activity as crude prices plunge (February 2024)

- U.S. producing gas wells increase despite low prices (February 2024)

- U.S. oil and natural gas production hits record highs (February 2024)

- Dallas Fed: E&P activity essentially unchanged; optimism wanes as uncertainty jumps (January 2024)

- Enhancing preparedness: The critical role of well control system surveys (December 2023)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)