UBCTD system uses Internet technologies to ensure reliable data handling

For a recent Underbalanced Coiled Tubing Drilling (UBCTD) job in Western Australia, it would have been possible for a directional driller to have steered the directional drilling assembly from the comfort of an office in the UK over satellite Internet. While this might not be desirable for a variety reasons, it shows the capability of modern communications and computing systems.

The same Internet technology that makes ecommerce and online banking possible can be applied to high-data-rate oilfield applications, because the fundamental requirements are the same. Namely, to provide timely, reliable, secure data to remote users. In place of static web pages, the most useful web applications that people are familiar with deliver data from databases. This mirrors what happens in high-data applications, such as UBCTD, so the same technologies can be used.

Another feature of the Internet is that servers in data centers are managed remotely, so there is software adapted specifically to configure, monitor and control hardware at a distance. This is exactly the capability that is beneficial in the oil field, where the field hands often don’t have advanced IT skills and, even if they did, they don’t have the time to put them to use, because that is not their primary task.

Most applications are not as data-intensive as UBCTD, so if high-data applications can be made to work effectively, the same technology can work for simpler applications. To get an understanding as to why UBCTD is so data-intensive, it is worth thinking for a moment about the measurements being acquired. In these systems, downhole data come up at electric wireline speeds rather than slow, mud pulse speeds—it also is transferring data from up to 200 sensors at any one time. These downhole data must be combined with surface data from the CT rig and the flowback equipment in real time. Add in the complication of these data points being controlled by different providers, and you start to understand the processing power required.

In short, it means that ad hoc methods of data transfer are no longer viable.

THE DEVELOPMENT OF WELLSITE IT OVER TIME

Before the advent of the PC, the most sophisticated piece of IT at the wellsite was the wireline logging truck. As PC technology became more widespread, PCs appeared on wellsites for reporting, email and data acquisition. From the first time that someone took a computer to a wellsite, the industry has always been keen to harness what technology has to offer. However, the evolution has not been without its problems and, in many cases, the solution has been an ad hoc fix rather than a high-quality strategy. Everyone has a tale to tell about IT at the wellsite.

There are the practical issues. Wellsites are rugged environments that require robust equipment. Consumer-grade equipment is so much cheaper and readily available than specialist ruggedized equipment, so it gets used in preference. But dust and other contaminants often shorten the useful life of consumer grade equipment.

It’s difficult to remember the day when not everything was WiFi-enabled. Cables were strung across the wellsite, and how many hours have been lost, repairing a communications cable that has been damaged by a truck driving over it?

When WiFi did become available, many of us can recall instances where the source of a slow-running communication link was tracked down to a crew member streaming video on their mobile phone. That was made possible, because the network password was shared more widely than intended.

Then there’s what happens at the end of a job. With data stored on desktop computers, it’s all inaccessible between the time it’s packed up and the time it arrives back at base, losing valuable post-job processing and reporting time. These delays create inefficiency and cost money.

These are all signs of an IT system under limited control with all the associated security risks and performance issues. This is not a desirable or efficient way to operate, and with readily available technology, things can be improved dramatically.

HOW INTERNET TECHNOLOGIES HELP

The Internet is an integral part of modern life. It has been able to become so pervasive because of its speed, reliability and ubiquity. Long gone are the days of dialling up over a phone line and logging into a single server, which would display static web pages. Now it is all about load-balanced server farms, redundant databases that power ecommerce, and network switches that efficiently and quickly connect New York to London and to Tokyo without any extra effort by the user.

A lot of time and billions of dollars have been spent to improve the technology necessary to enable companies to move their business online. For this to happen, the IT tasks that keep the system running have had to be automated. A feature of the way that the modern Internet is managed is that the person doing the managing is very rarely anywhere near the physical hardware being used, and the end-user needs almost no understanding of the technologies to be able to use its functions.

In oilfield terms, the wellsite crews are the equivalent of consumers who want to take advantage of IT, not run it. This has been made possible by having many applications run directly on the web through a browser, without having to download any extra programs to their device. These so-called web apps can be updated centrally, and all updates are available to end users at the same time.

This same concept can be applied to the wellsite by putting a mini-data center at the heart of the wellsite IT system and ensuring that there is reliable connectivity to it. With the mini-data center, on-site quality-of-service to local users is maintained and, with a good Internet connection, it essentially becomes another part of the cloud for the purposes of management and remote data processing.

THE WELLVAULT MINI-DATA CENTER AT THE WELLSITE

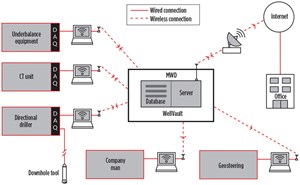

The journey to a better wellsite IT system is to treat it as an integral part of the wellsite, central to the way that the wellsite operates, rather than as an added productivity tool added later. In a UBCTD setup, the time between rig up and rig down is relatively short (a few days) and there is no existing installation, such as a rig communication system to plug into. Even if there was, it wouldn’t necessarily be configured for the large amounts of data that are part of an underbalanced drilling operation, Fig. 2.

What follows is a list of the essential and necessary features.

Environmental protection. Heat, cold, water, dust and vibration are the enemies of delicate IT equipment at the wellsite. These all can be addressed, but sometimes the measures conflict with each other. For example, one good way of combatting the effects of dust is to specify fan-less computers. But all computers generate heat, so the fan-less feature may have been made possible by slowing the computer clock speed with a knock-on effect on performance. So, if performance is critical, it will be necessary to provide dust protection and filtering for fan-cooled computers. Protective cases can isolate equipment from shock and vibration in use and during shipping.

Internet connection. Each location will have an optimum way of connecting to the Internet, be it via satellite, mobile internet and, in some cases, microwave link. What is essential is that the connection is planned and tested, rather than being considered as an afterthought or nice-to-have feature, as may have happened in the past.

Data interfaces and displays. Individual data displays are placed around the wellsite to provide the communication required for an integrated operation, such as UBCTD. These also serve as a connection to third-party data sources and the driver of the WiFi access points.

Long-range point-to-point WiFi. Specialist WiFi access points provide longer range than consumer items. The biggest challenge here is to be able to offer a range of secure fixing methods that can be placed, as required, preferably on the outside of cabins with reliable cable entry into the cabin.

Remotely configurable routers. To ensure equipment can be monitored and maintained remotely to avoid costly downtime, every device needs to be configurable remotely. Consumer products are readily and cheaply available, but they do not give the control of configuration or the feedback of data required for a remotely controlled industrial system. On the other hand, enterprise-grade devices do offer the level of configurability and data feedback required.

Redundancy. To ensure reliability, especially in situations where there is limited IT knowledge on-site, a robust redundancy setup is required. This means at least two servers operating concurrently—one of which serving as a backup—so that, in the event the first server goes down, operation can switch to the backup servers without a loss of data. Currently, the switch over is made with the intervention of a remote engineer, but newer technologies exist to enable the switch over to happen automatically, without any human intervention, potentially removing server failure as a cause of any downtime.

Encryption and access control. When it comes to information security, end-to-end encryption is essential, and each device has to have its own firewall and anti-virus software. To prevent the system being used by crew members for non-operational reasons, access should be limited, using IP address control.

CASE STUDY

In a recent project in Australia, UBCTD was used to drill a multi-lateral well with RockSense porosity log used for geosteering, Fig. 3. The objective was to drill two laterals in the reservoir section. It showed the advantages of the new WellVault mini-data center. The remoteness of the operation in Australia, 1,200 km (746 mi) north of Perth, and the fact that the support locations were in the U.S. and the UK, meant that travel times were up to two days to bring in equipment and support staff, if required. So, it was essential that equipment reliability was high and that it could be configured remotely. The requirement was to send real-time data and logs to the client’s office in Perth and back to the UK for interpretation. Also, the equipment maintenance data and inventory usage needed to be recorded in the cloud-based ERP system, to provide daily updates about cost and any pending spares or stock requirements.

This was the first operation, where it was not deemed necessary to send a dedicated IT engineer to provide pre-job setup. A satellite link from the wellsite provided an Internet connection. The WellVault data center was configured, so that it automatically provided a secure VPN connection back to the UK, and any further setup tasks were done remotely. WiFi access points were set up around the wellsite by the local crew to provide connectivity to the underbalance equipment and the coiled tubing unit. Their data were provided in WITS format, and these communication links had been tested before the job started.

Reliable, if slow, satellite Internet connection meant that the wellsite database could be replicated in the UK for job support, troubleshooting, and to create the RockSense log for geosteering. At the wellsite, the equipment had to endure extreme heat and pervasive dust. The value of a robust Internet setup was proven, when there was a server power supply failure on-site. Whereas a less-sophisticated setup might have stopped the operation for a few hours to swap hardware, and would have created data splicing problems later, the new redundant setup allowed the backup server to be activated remotely, minimizing downtime.

CONCLUSION

For advanced drilling applications, the era of ad hoc IT systems at the wellsite has ended. They do not meet the modern needs of functional capability, reliability, security or remote control required. Internet data storage and communications technologies have now developed to a point where it is possible to place a portable, Internet-connected, mini-data center at the wellsite. The benefit is that data security and equipment uptime can match the capability of larger systems. Suitable precautions need to be taken to physically protect hardware from the wellsite environment, in a way that is not required in clean room environments. With care, this is achievable without too much difficulty.

Most operations are not as data-intensive as UBCTD, but the era of integrated wellsite IT systems pulling in data from multiple sources and streaming it to town is definitely upon us. Wellsite crews are as busy as they have always been, without having to support another piece of equipment. In reality, most are employed for their willingness to do field work, rather than fix computers.

Implementation of the latest Internet technologies at the wellsite with remote control leaves wellsite crews to focus on their primary job roles. It helps reduce the need for people at the wellsite and puts control of IT hardware and data with the IT department, where it can be managed and kept secure. The Internet didn’t develop to where it is today without adapting to the ways that users interact with it. Oilfield IT needs to similarly adapt to reap the full advantage of the digital transformation.

- Digital transformation/Late-life optimization: Harnessing data-driven strategies for late-life optimization (March 2024)

- The reserves replacement dilemma: Can intelligent digital technologies fill the supply gap? (March 2024)

- Digital tool kit enhances real-time decision-making to improve drilling efficiency and performance (February 2024)

- Digital transformation: Digital twins help to make the invisible, visible in Indonesia’s energy industry (January 2024)

- Digital transformation: A breakthrough year for digitalization in the offshore sector (January 2024)

- Quantum computing and subsurface prediction (January 2024)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)