Increased oil recovery possible with CO2 EOR in low-pressure reservoirs

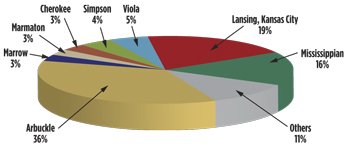

JYUN-SYUNG TSAU, Tertiary Oil Recovery Project The use of CO2 to energize and recover immobile oil in enhanced oil recovery (EOR) projects has been practiced for many years. However, application of this technique in shallow-depth oil fields with lower pressures, at which CO2 is at near-miscible conditions, has not been broadly investigated. With significant oil resources in the U.S. that could potentially be recovered with additional understanding of the near-miscible approach, it is obvious that this technique should be evaluated for future use. Presented below are results from an investigation of the feasibility of near-miscible CO2 flooding for EOR in a Kansas Arbuckle reservoir. The studies were performed to characterize phase behavior, the displacement process and oil recovery under near-miscible conditions. Additionally, the CO2 sequestration potential of the Arbuckle reservoir was investigated. Simulation results indicate that near-miscible displacement is achievable at current reservoir operating pressure, and incremental oil recovery generally increases with injection pressure. Oil recovery efficiency was increased by 1.3% to 4.8% as a result of CO2 injection STUDY SUMMARY Two study phases were performed: 1) an experimental study; and 2) a computational approach. In the experimental studies, phase behavior tests between CO2 and Arbuckle crude oil were carried out to define near-miscible conditions at reservoir temperature. Core flooding tests were conducted to evaluate oil recovery at near-miscible conditions, with pressures varying from 1,150 psi to 1,350 psi. Recovery of over 50% of the waterflood residual oil saturation was observed, when CO2 was used to displace Arbuckle oil from Berea sand, Baker dolomite and Arbuckle dolomite cores. At near-miscible conditions, extraction appears to be the primary mechanism for mass transfer between hydrocarbon components and CO2. However, the reduction of oil viscosity by a factor of five occurred, when CO2 dissolved in the oil. This suggests that some of the additional oil recovery may be attributed to reduction of the mobility ratio between CO2 and resident oil. In the computational study, a 47-acre lease containing four wells was extensively examined for the effect of CO2 injection pressure, rate and pattern on the oil recovery efficiency. Average reservoir pressure was maintained at near-miscible conditions during CO2 injection, since the pressure was supported by the underlying aquifer. In general, simulation results show that improvement of oil recovery at near-miscible conditions is achievable under the current reservoir operating pressure. Incremental oil recovery was increased with injection pressure. Oil recovery efficiency was increased by 1.3% to 4.8% as a result of CO2 injection. This improved recovery efficiency likely results from the improvement of relative mobility ratio of the CO2 and oil, and the efficacy of CO2 extraction. However, recovery efficiency is affected by reservoir heterogeneity as found in the pattern design, where the recovery results depend on the placement of injectors. The theoretical storage capacity of CO2 in this 47-acre lease was estimated to be 1.58 Bscf. With 1.45 Bscf of CO2 injected in ten years, the effective storage capacity of CO2 varied from 39% to 63%. A pilot field test based on these results is being designed. BACKGROUND Carbon dioxide injection for EOR is a proven technology. It is also considered as one of the most promising methods for carbon sequestration in geological formations. CO2 injection projects for EOR are normally operated at a pressure above the minimum miscibility pressure (MMP), which is determined by crude oil composition and reservoir conditions. However, many reservoirs in the U.S., and around the world, are at shallow depths or under geological conditions, such that they operate at pressures below MMP. In this case study, an Arbuckle reservoir in the Bemis-Shutts field, Trego County, Kansas, has a MMP of 1,400 psia, while the current maximum operating pressure is at 1,100 psia in a large portion of the field. Another part of the Arbuckle reservoir has a MMP of 1,350 psi, while it is operating at a reservoir pressure in the neighborhood of 1,150 psi. Arbuckle reservoirs in Kansas are a frequent target and significant resource for EOR. These reservoirs have produced an estimated 2.2 billion bbl of oil, representing 35% of the 6.1 billion bbl of total oil production in Kansas, Fig.1 (after Franseen, et al., 2004). Most Arbuckle reservoirs have active water drives, which have maintained reservoir pressure at 1,000 to 1,100 psig through nearly 50 years of production even though millions of barrels of fluid have been produced. Early studies of CO2 miscible flooding indicated that miscibility is not achievable at the reservoir operating pressure in most Arbuckle reservoirs.

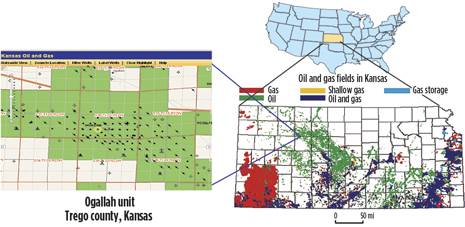

Currently, over one hundred small producers are operating in Arbuckle reservoirs. Unless an alternative technology and approach are introduced, many of these fields in central Kansas will be abandoned with substantial, remaining oil left in place. The target oil field is operated by Carmen Schmitt, Inc., Fig. 2. The unit produces from the Arbuckle formation (3,950 to 4,060 ft), as well as other formations above the Arbuckle (Marmaton and Lansing-Kansas City). The Arbuckle formation is associated with a structural high as part of the central Kansas uplift, and is thin-to-absent in parts of northeastern Kansas (after Franseen, et al., 2004). Reservoir temperature ranges from 92°F to 130°F, with an average temperature of 110°F. An active water drive has maintained reservoir pressure at about 1,150 psi.

Primary production of the Ogallah began in 1951. Well production history shows that no water was produced before 1960. Water breakthrough in producers began after 1960, and due to the high water production, wells were worked over by plug-back operations and recompletion at higher intervals. At peak of production in 1969, the Ogallah field had 85 wells producing wells 1.07 million bbl of oil per year, with cumulative output of 11.37 million bbl by 1969. After 1969, the field commenced commingled-production with the Lansing-Kansas City formation. The Ogallah field was unitized in 1991, and the number of active producers since then has been reduced to 18. The study’s goal was to demonstrate that near-miscible CO2 injection can substantially increase oil production with CO2 injection pressures below the MMP. Success with CO2 injection at near-miscible conditions may lead to development of CO2 projects operated by small producers in reservoirs, where the MMP is not attainable at current operating reservoir pressures. The net result could be significant additional oil recovery in the U.S. Results from experimental and computational studies to characterize and demonstrate the phase behavior, the displacement process and the oil recovery potential under near-miscible conditions are summarized. The experimental approach was conducted in four parts: 1) slim-tube experiments; 2) swelling/extraction tests; 3) phase behavior modeling; and 4) core flow tests. In the computational studies, the methodologies of developing a reservoir model, and assessment of the potential recovery processes at near-miscible condition by numerical simulation, were conducted. The simulation results of oil recovery at near-miscible conditions in a 47-acre oil field lease were assessed. Readers are directed to the comprehensive final report (see references), available by request. The experimental work included fundamental studies of phase behavior for the CO2/crude oil system, and the displacement process at near-miscible conditions. Swelling tests were performed to determine the relationship between saturation pressure, swelling factor and CO2 volume injected. Extraction tests were conducted to examine extraction of liquid hydrocarbon into the CO2 -rich phase and the effect of pressure on extraction. A phase behavior model, based on the Peng-Robinson equation of state, was used to characterize the experimental phase behavior interaction between CO2 and oil. Core flow tests were performed at pressures at near-miscible conditions, in which the effect of CO2 injection pressure and water saturation on oil recovery was evaluated. Completion of these experimental studies allowed development of a representative flow model to simulate near-miscible displacement physics and extend it to simulate CO2 injection process in a reservoir model of the oil field.

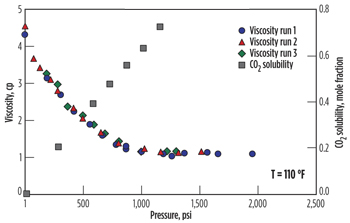

RESULTS SUMMARY Experimental studies. From experimental studies, MMP in the study area reservoir was estimated to be 1,350 psig at 110°F and 1,650 psig at 125°F. Miscibility is not achievable at the current reservoir pressure of 1,150 psig. The near-miscible pressure conditions investigated in core flow tests were from 1,100 to 1,350 psig. At current reservoir pressure of 1,150 psig, and a temperature range of 110°F to 125°F, the recovery efficiency of the original oil in place from slim-tube experiments varied from 78% to 83%, which is attributed to mass transfer mechanisms between the crude oil and CO2 during the displacement process. Carbon dioxide solubility increases with increasing pressure and decreases with increasing temperature. As a result of CO2 dissolution into the liquid phase, the liquid phase swells. The degree of swelling depends on pressure and temperature. The pressure at which CO2 begins to extract significant amounts of hydrocarbons rises with increasing temperature. Significant extraction started at a pressure of 1,150 psig and 110°F. Extraction or vaporization of hydrocarbons into the CO2-rich phase is the primary mechanism for oil recovery in the near-miscible region, from 1,100 psig to 1,350 psig at 110°F Tertiary oil recovery efficiency varied among rock types. For dolomite, from 65% to 80% recovery efficiency was measured. For sandstone, from 45% to 60% was measured in the near-miscible region (from 1,100 psig to 1,350 psig at 110°F). Recovery of more than 60% of the waterflood residual oil was obtained, using an Arbuckle reservoir core when CO2 was injected at the current average reservoir pressure of 1,150 psig at 110°F. Experimental work showed that presence of the water phase improved the relative permeability of CO2, which when coupled with the reduction of oil viscosity, reduced the mobility ratio between the oil and CO2; and therefore, recovery efficiency was improved. A nearly five-fold reduction in oil viscosity was achieved in the near-miscible region with CO2 injection, Fig. 3. The reduction of oil viscosity improved the total mobility ratio between reservoir oil and displacing fluid, which affects the recovery efficiency in a favorable way. Viscosity measurements are useful in tuning the phase behavior model.

Computational study. The computational study was conducted in two parts: 1) methodologies to develop a geological model; and 2) reservoir simulations to assess the oil recovery and CO2 sequestration potential through CO2 injection at near-miscible conditions. The geological model was developed by a well-log interpretation and cross-plotting method. Reservoir simulations were performed to investigate the pattern design of CO2 injection on oil recovery and carbon sequestration. The simulation results of oil recovery and CO2 sequestration at near-miscible condition in a 47-acre oil field lease were calculated and reported. The geological model was developed, based on well-log interpretation and a cross-plotting method. An in-house-developed correlation between resistivity log and porosity log was successfully applied to calculate porosity, based on microlog measurements. This approach was necessary, due to the vintage of available well log data. The primary production history of a 47-acre lease containing four wells was reasonably matched. This lease was extensively examined for near-miscible CO2 injection effectiveness. Simulation results indicate that near-miscible displacement is achievable at the current reservoir operation pressure. Incremental oil recovery generally increases with injection pressure. Oil recovery efficiency was increased by 1.3% to 4.8% as a result of CO2 injection. CONCLUSIONS Properties of Ogallah unit oil produced from an Arbuckle reservoir in Kansas were determined at reservoir temperature from a series of phase behavior and slim-tube experiments, in which CO2 was dissolved in, or used to displace, the oil. MMP at 110°F was 1,350 psig, and increased to 1,650 psig when temperature increased to 125°F. At near-miscible conditions (pressure greater than 1,100 psig but less than the 1,350 psig MMP), oil viscosity was reduced by a factor of five, due to the dissolution of CO2. Phase behavior data were used to develop an equation of state that correlated properties of CO2-saturated crude oil as a function of pressure at reservoir temperature. Recovery of more than 50% of the waterflood residual oil from Berea sand, Baker dolomite and Arbuckle reservoir rock was obtained, when CO2 was injected at the current average reservoir pressure of 1,150 psig, substantially less than the MMP (1,350 psig). Excellent agreement was observed between simulated and measured oil recovery from slim-tube tests for CO2 injection over pressures ranging from 1,000 to 1,500 psig. Significant extraction of oil by CO2 started at a pressure of 1,150 psig, which indicated that extraction/vaporization is the primary mechanism for oil recovery in the near-miscible region from 1,100 to 1,350 psig at 110°F. At near-miscible conditions, relatively high recovery efficiency in the slim-tube experiment supports extraction/vaporization as a principle displacement mechanism. REFERENCES

|

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)