April 2012

Supplement

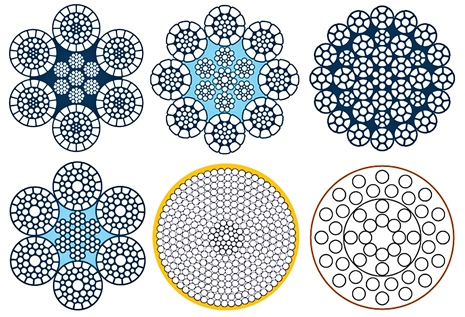

Longer, stronger ropes extend deepwater capabilities

International rope manufacturer Bridon is expanding the capabilities of offshore heavy-lifting systems. The historical challenge in deepwater operations has been to deploy 300 tonnes in 3,000 m (9,843 ft) of water. Now, as operators seek to reach greater depths, industry is increasingly demanding lifting systems that can deploy weights of 400 tonnes at depths up to 4,000 m (13,123 ft).

- Mixed outlook for activity on the UK Continental Shelf (December 2023)

- X80 heavy wall pipe solutions for deep/ultra-deepwater field developments in mild sour environment (November 2023)

- Wellbore seal control and monitoring enhance deepwater MPD operations (October 2023)

- Novel approaches to deepwater steel catenary production riser life extension benefit ESG (September 2023)

- Advancing casing drilling to deepwater: Rethinking top hole well construction (August 2023)

- Oil States’ Taylor sees pick-up in OFS business in deepwater and international sectors (June 2023)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)