|

United Kingdom |

|

Unique downhole valve boosts circulating options

|

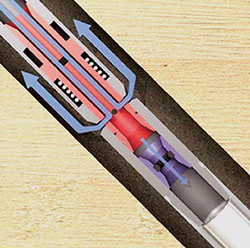

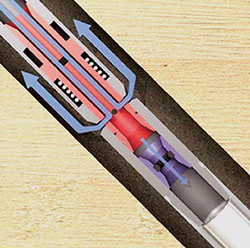

Clean up while drilling – boosting annular velocity with the downhole CCV.

|

|

SPS International, a supplier of pre-completion wellbore cleanup tools and services, has launched a new Centurion Circulating Valve (CCV), which extends the capabilities of previous drop-ball or flow-activated circulating valves through a series of technological advances. It has been developed for use primarily in drilling, when high circulating rates or an alternative flow path is required.

The tool’s unique features promote the effective removal of cuttings beds, as well as effective spotting of lost circulation-material pills without affecting sensitive BHA components. Flow splitting while drilling is another option that allows optimum flow hydraulics through the BHA while maximizing hole cleaning and minimizing the formation of cuttings beds in extended reach wells. For the first time, therefore, drilling can continue while maximum pump rates clean the well and the bit simultaneously.

The CCV is dormant until a steel activating ball lands on a seat and pressure is applied. While the valve itself is available in three different sizes, for a given valve, the same-size steel ball is used to close the tool, with the same pressure applied as that used to open the tool. While open, a small amount of fluid still flows through the bit, keeping the BHA lubricated. Wireline access can still be made through the tool in either the open or closed position, which is important if, for example, a radioactive source has to be retrieved. Additional applications and benefits include jetting wellheads and BOPs, allowing drill pipe to be pulled dry, displacing fluids at enhanced rates and various wellbore cleanup scenarios.

The downhole valve tool is designed to be an effective enhancement to drilling operations and is catching on quickly with operators. Although new, it has already been deployed by several operators in almost 50 operations worldwide. Previously, drilling had to cease when the drillstring picked up off bottom, while the annulus was pumped clean of cuttings. In many cases, one had to wait for a ball to drop to open a pressure relief valve above the BHA, and then still more time waiting for one to close it. The CCV eliminates all that, thus significantly reducing time spent.

|